Incoming water pretreatment device for constructed wetland system and method thereof

A technology of constructed wetland system and pretreatment device, which is applied in the direction of aerobic process treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc. Sufficient, high economic cost and other issues, to achieve the effect of improving water quality, avoiding water hammer effect, and reducing the occupied area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

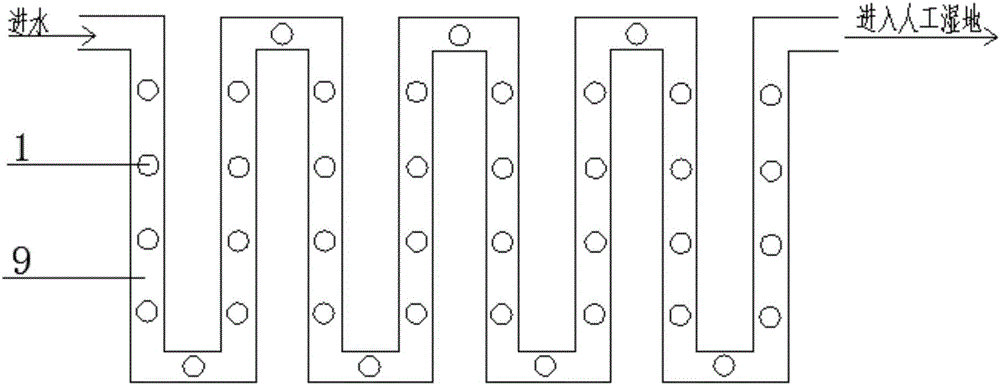

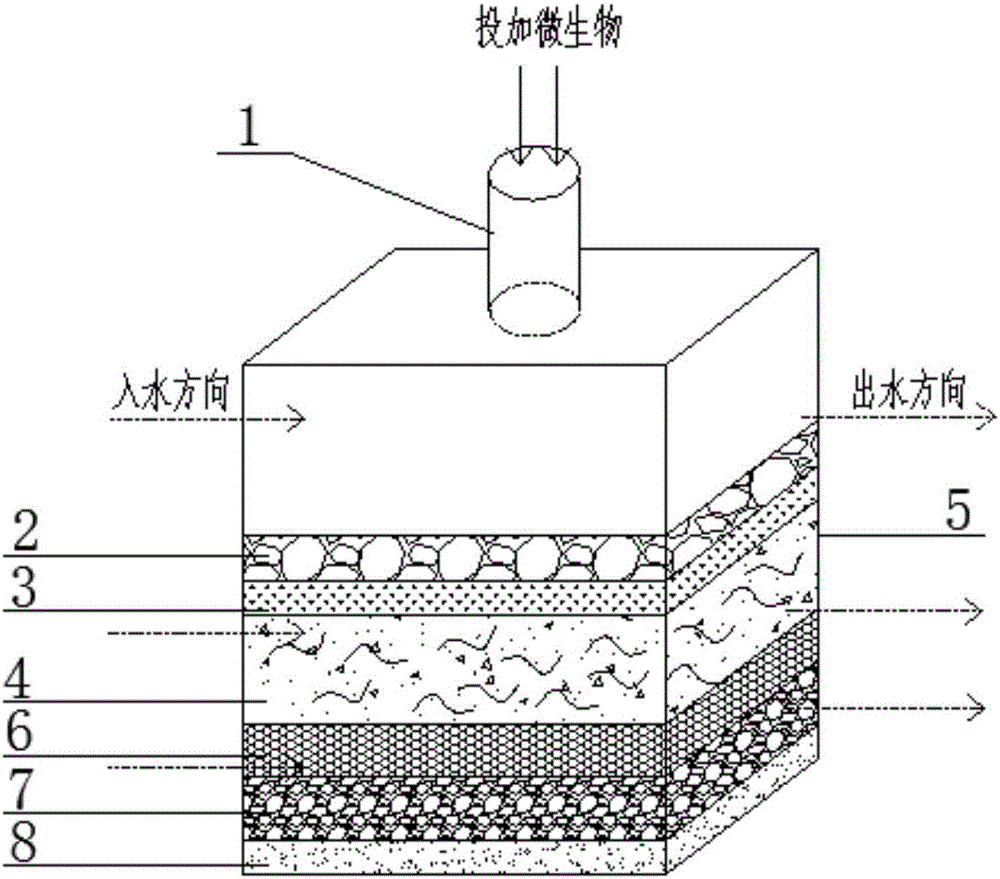

[0027] Embodiment 1, reference figure 1 and image 3 .

[0028] Including a square pipe 5, the bottom of the square pipe 5 is provided with a packing layer, the height of the packing layer accounts for 2 / 3 of the height of the square pipe 5, and the packing layer is divided into a physical filter layer and an earthworm filter layer from bottom to top , a circular air vent 1 is provided directly above the square pipe 5 .

[0029] The physical filter layer is a fine sand layer 8, a vermiculite layer 7 and a ceramsite layer 6 from bottom to top.

[0030] The earthworm filter layer includes humus layer 4, fiber layer 3 and gravel layer 2 from bottom to top.

[0031] The height*width of the cross section of the square pipe 5 is (0.8-1.2)m*(0.5-0.7)m, the height of the upper part of the square pipe 5 is 0.25-0.35m, and the thickness of the earthworm filter layer is 0.3- 0.5m, the thickness of the physical filter layer is 0.25-0.35m.

[0032] The thickness of the fine sand layer...

Embodiment 2

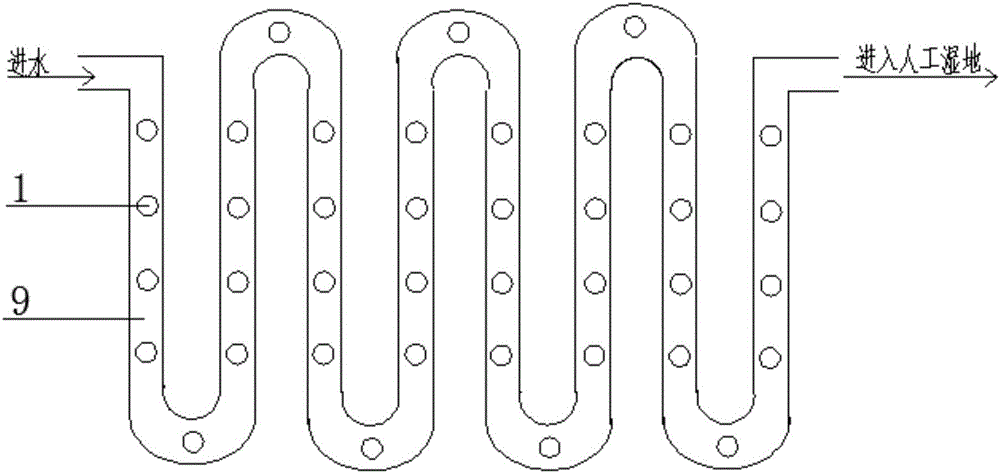

[0042] Embodiment 2, refer to figure 2 and image 3 .

[0043] Including a square pipe 5, the bottom of the square pipe 5 is provided with a packing layer, the height of the packing layer accounts for 2 / 3 of the height of the square pipe 5, and the packing layer is divided into a physical filter layer and an earthworm filter layer from bottom to top , a circular air vent 1 is provided directly above the square pipe 5 .

[0044] The physical filter layer is a fine sand layer 8, a vermiculite layer 7 and a ceramsite layer 6 from bottom to top.

[0045] The earthworm filter layer includes humus layer 4, fiber layer 3 and gravel layer 2 from bottom to top.

[0046] The height*width of the cross section of the square pipe 5 is (0.8-1.2)m*(0.5-0.7)m, the height of the upper part of the square pipe 5 is 0.25-0.35m, and the thickness of the earthworm filter layer is 0.3- 0.5m, the thickness of the physical filter layer is 0.25-0.35m.

[0047] The thickness of the fine sand layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com