Pipeline-type mixed heating equipment

A heating equipment, hybrid technology, applied in the direction of lighting and heating equipment, direct contact heat exchanger, heat exchanger type, etc., to achieve the effect of eliminating noise, original structure, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

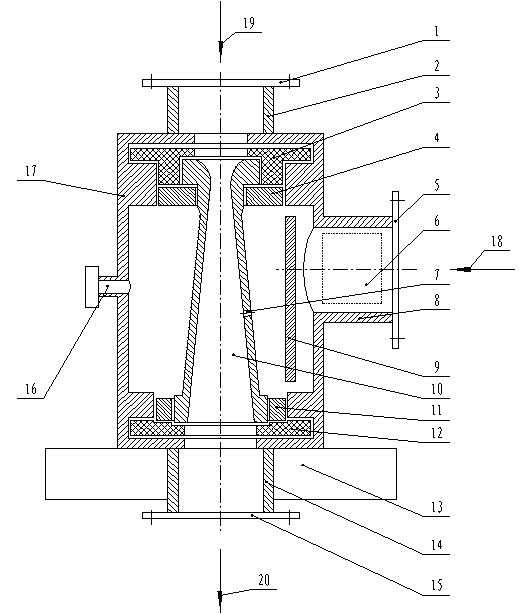

[0022] 1. The liquid flows through the inner core, and the steam in the cavity injects (or inhales, adds) into the liquid through numerous φ3—φ10 oblique small holes on the inner core wall, and directly contacts and mixes with the liquid to heat the liquid .

[0023] 2. Because the direct mixing of steam and water is easy to cause vibration, the vibration-absorbing devices A and B located on the outer circle of the inner core are absorbed and eliminated. The vibration-absorbing device is composed of vibration-absorbing materials.

[0024] 3. The generated noise, the noise in this section of the inner core is absorbed by the silencer A located on the periphery of the inner core. The sound-absorbing device is composed of multi-layer small-hole mesh panels and sound-absorbing materials with different arrangements of φ1-φ4 to achieve the effect of eliminating sound.

[0025] 4. The noise at the outlet of the mixed water is absorbed by the muffler B at the outlet of the mixed wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com