Pouring sealing method and pouring sealing structure for explosionproof LED lamp

A technology of LED lamps and LED lamps, which is applied to the safety devices of lighting devices, semiconductor devices of light-emitting elements, lighting and heating equipment, etc. It can solve the problems of poor curing effect, long curing time, and high curing temperature, so as to facilitate installation and maintenance , Lighting structure is compact, the effect of lighting structure improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

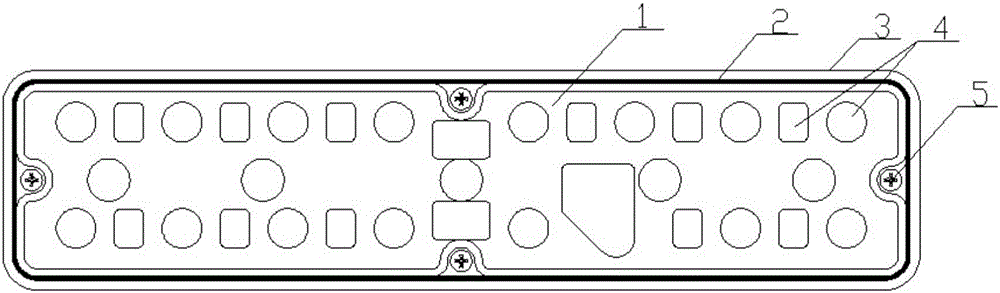

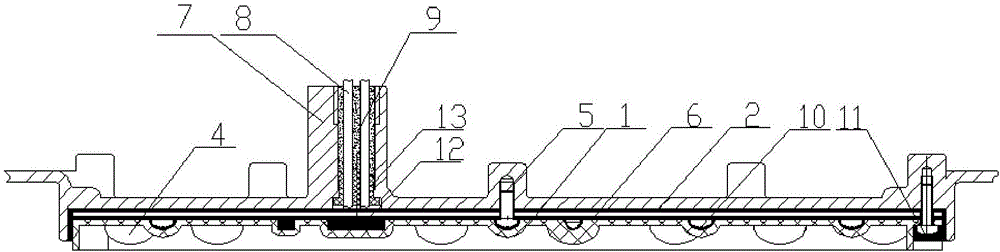

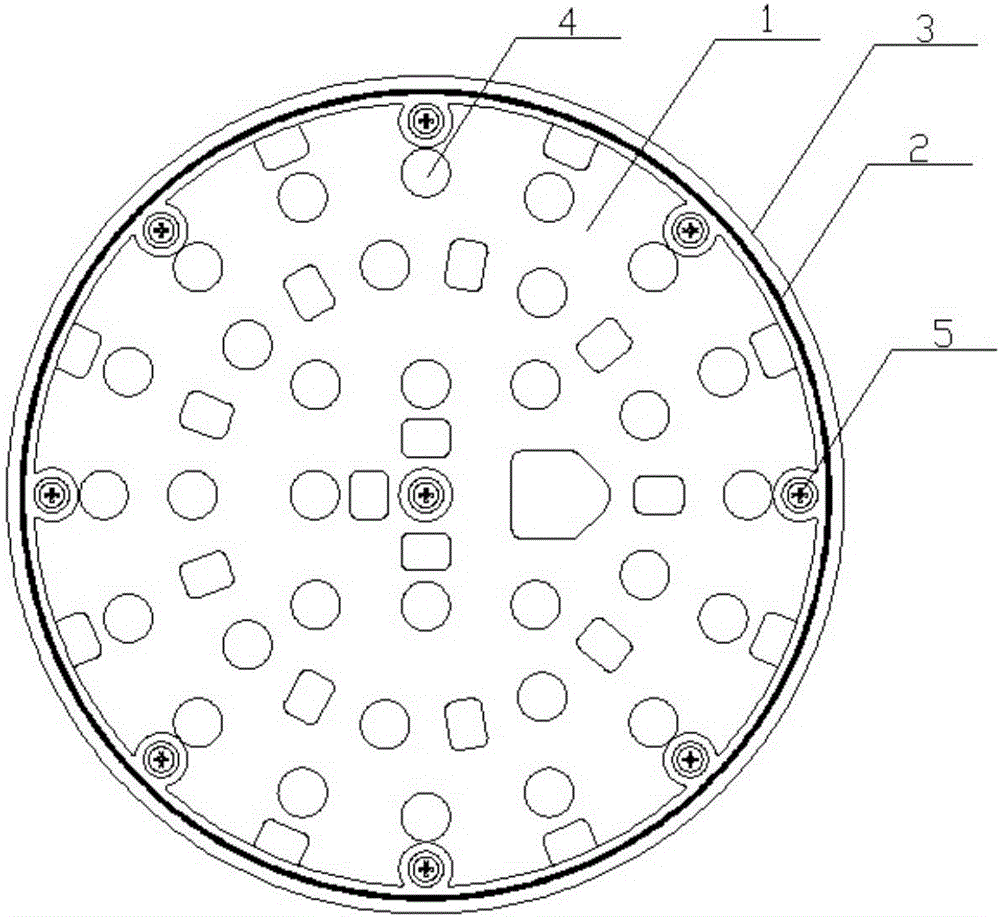

[0053] The present invention will be described below in conjunction with the accompanying drawings. Such as Figure 1-6 as shown, figure 1 It is a schematic diagram of the main viewing direction when the lens of the present invention is square. figure 2 It is a schematic diagram of the structure of the lens of the present invention when it is square. image 3 It is a schematic diagram of the front view direction when the lens of the present invention is circular. Figure 4 It is a schematic diagram of the structure of the lens of the present invention when it is circular. Figure 5 It is a schematic flow chart of the pouring method of the present invention. Image 6 It is a schematic diagram of the time and temperature control conditions of the curing process of the present invention.

[0054] The invention discloses a pouring method for an explosion-proof LED lamp, which includes the following steps:

[0055] A. Preparation of casting materials,

[0056] B. Stir and m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com