Sliding heat insulation pipe bracket with gradient

A technology of thermal insulation pipe and slope, applied in the direction of protecting pipelines, pipe components, pipeline protection through thermal insulation, etc., can solve the problems of insufficient precision and difficult slope, and achieve extended service life, pipeline protection, and compressive strength. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

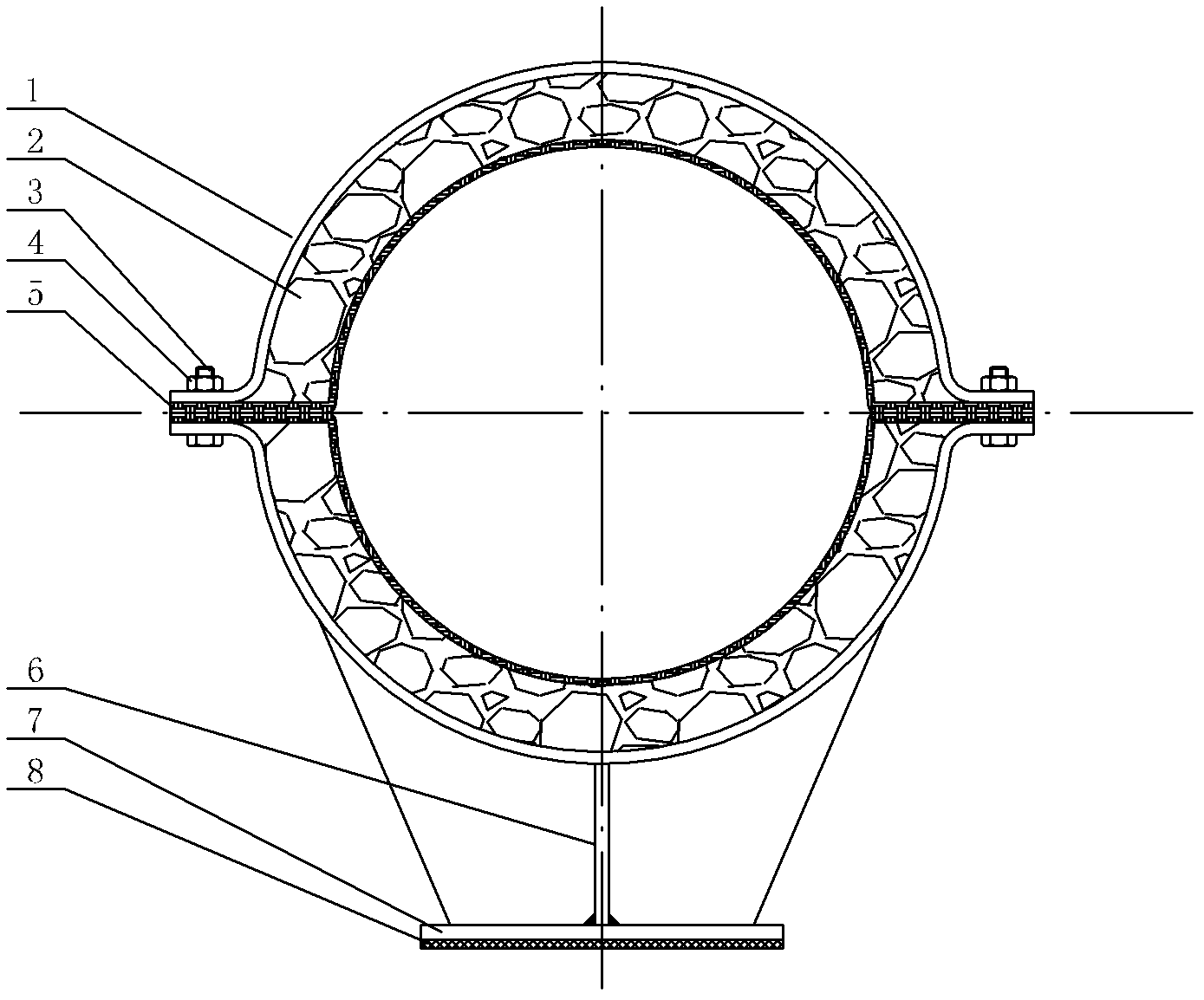

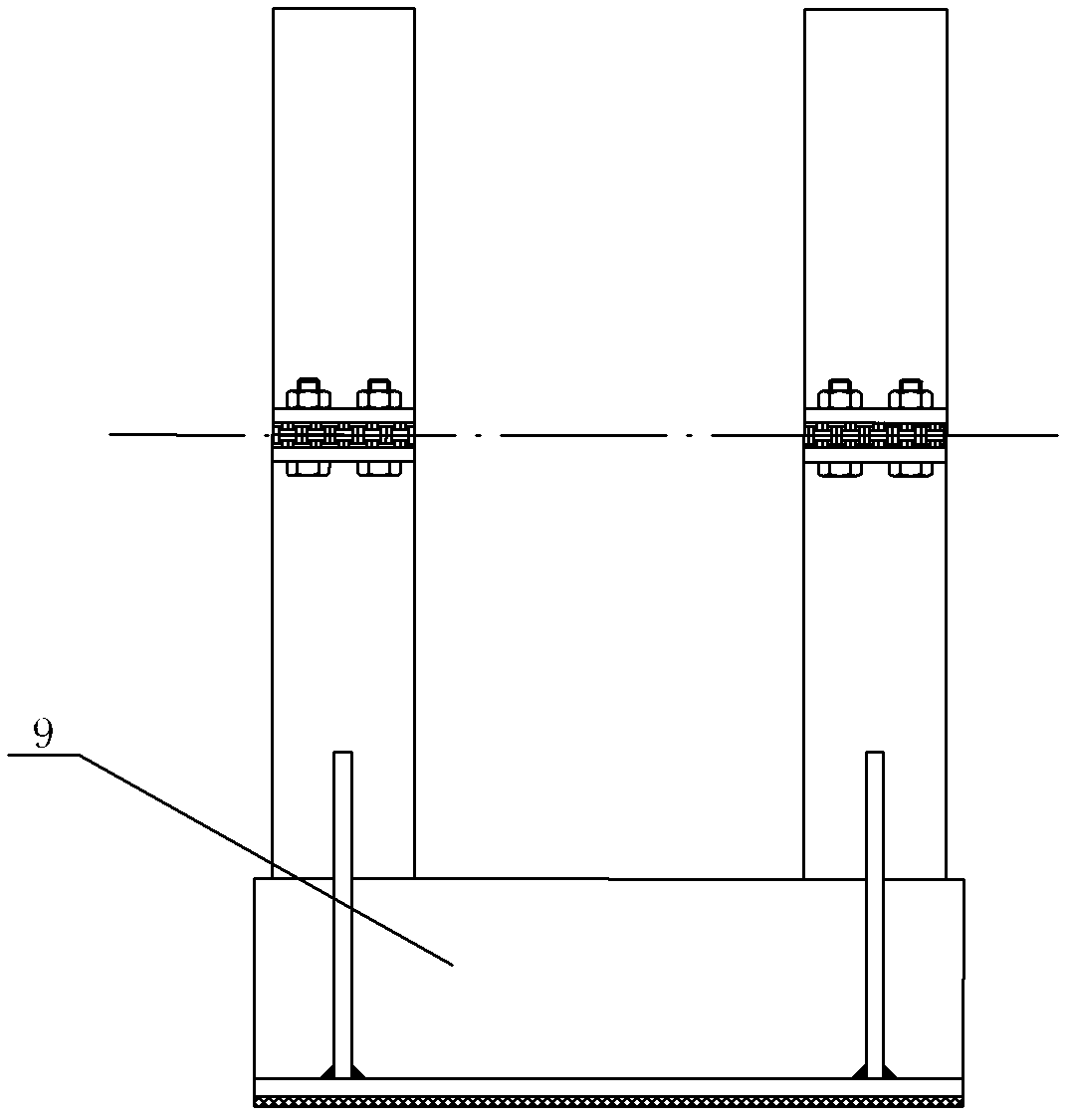

[0017] Such as Figure 1-Figure 3 As shown, a sloped sliding heat-insulating pipe support includes a heat-insulating pipe support and a base, and the heat-insulating pipe support is located above the base, and the two are integrated; The heat tile 2 and the heat insulation blanket 5, the two clamps 1 are semicircular, and there are fixed parts extending radially on the left and right sides. The shape of the two heat insulation blankets 5 is the same as that of the clamp 1, and the radius is smaller than that of the clamp 1. It is set inside the clamp 1 and spliced into a circle. The relative position of the clamp 1 and the heat insulation blanket 5 is fixed by the fixed parts extending from the left and right sides; the heat insulation tile 2 is filled between the clamp 1 and the heat insulation blanket 2 between;

[0018] The base has a rib plate 6, a support base plate 7, a slide plate 8 and a vertical plate 9; the sliding heat-insulating pipe supports are two, and are fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com