Open hole gravel packing tool and open hole gravel packing method for horizontal well

A gravel-packed, horizontal well technology, applied in the direction of production of fluids, etc., can solve the problems of tool sand stuck, incomplete well wall, difficult to wash balls, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In order to clearly illustrate the technical features of this solution, the following two specific implementation methods are used in conjunction with the accompanying drawings to illustrate this solution.

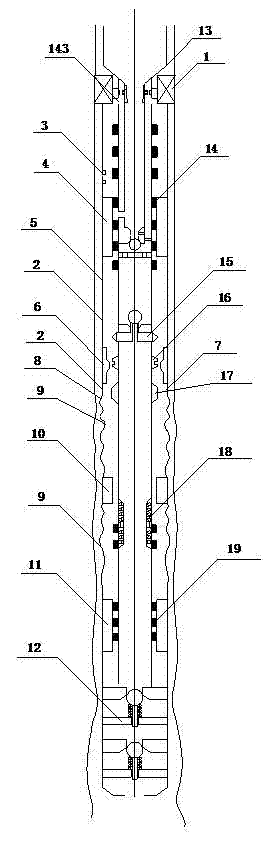

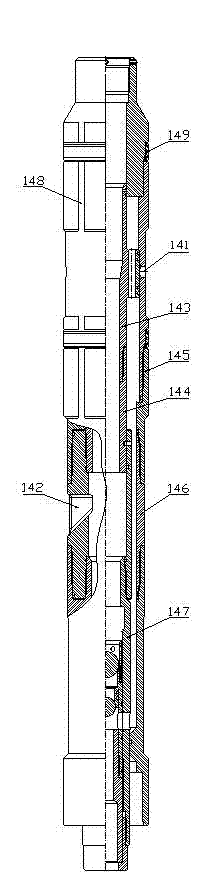

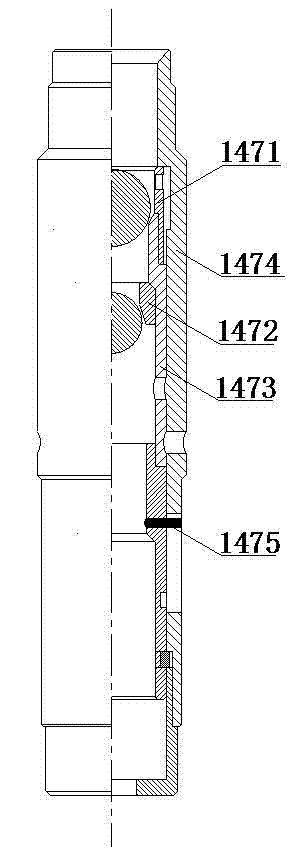

[0058] A kind of horizontal well openhole gravel packing tool of the present invention is as figure 1 shown. It includes an outer pipe string and a service tool. The service tool is located inside the outer pipe string. The outer pipe string includes a packer 1, an extension pipe 2, a packing sliding sleeve 3, a connection sealing cylinder 4, a connection collar 5, and an extension pipe connected in sequence. 2. Positioning collar 6, extension pipe 2, quick connector 7, blind pipe 8, screen pipe 9, screen pipe 9, screen pipe 9, liquid-proof lock pipe 11 and double-stage float shoe 12; service tools include The seat seal tool 13, the filling tool 14, the anti-suction valve 15, the sliding sleeve switch tool 16, the positioning tool 17, the classification screen valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com