Wear-resistant and high-temperature-resistant butterfly valve made of full-forged steel material and manufacturing method thereof

A technology of high temperature resistance and material, which is applied in the field of butterfly valves made of all-forged steel wear-resistant and high-temperature resistant materials and their manufacturing fields. , Easy to operate, strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

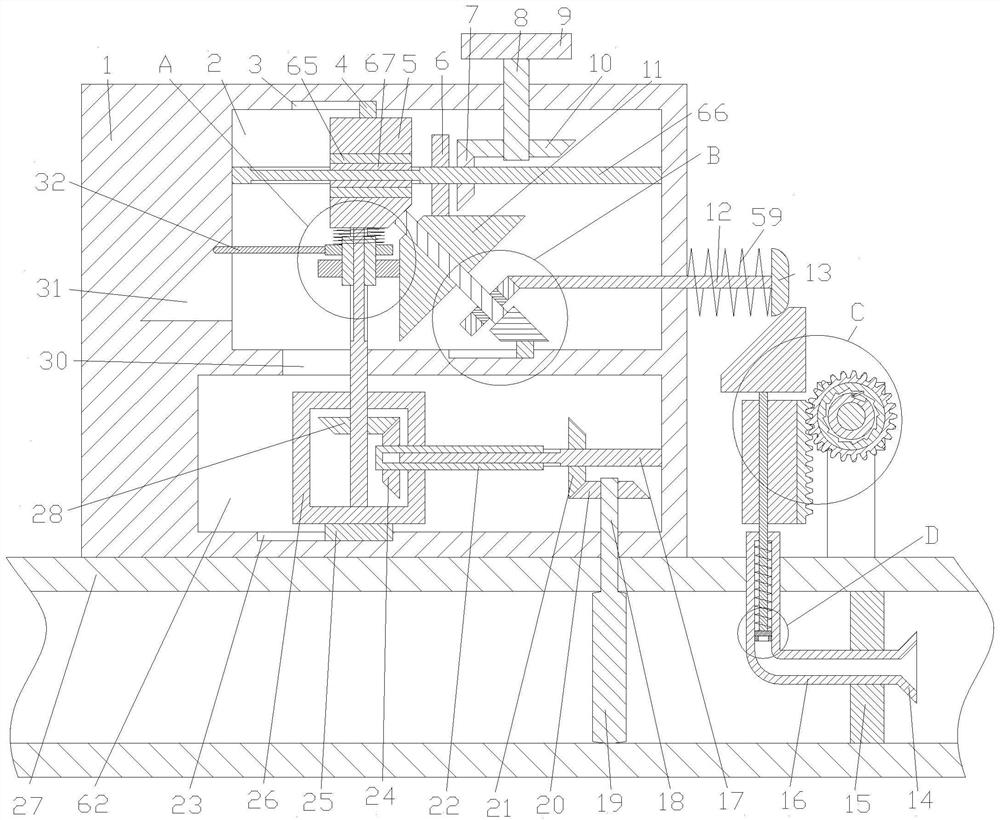

[0030] The present invention will be further described below in conjunction with accompanying drawing:

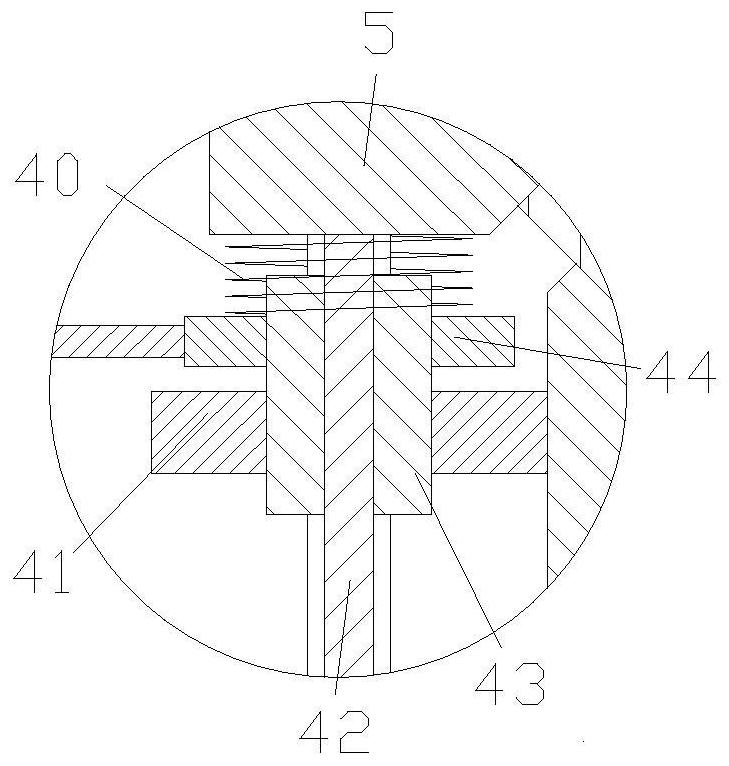

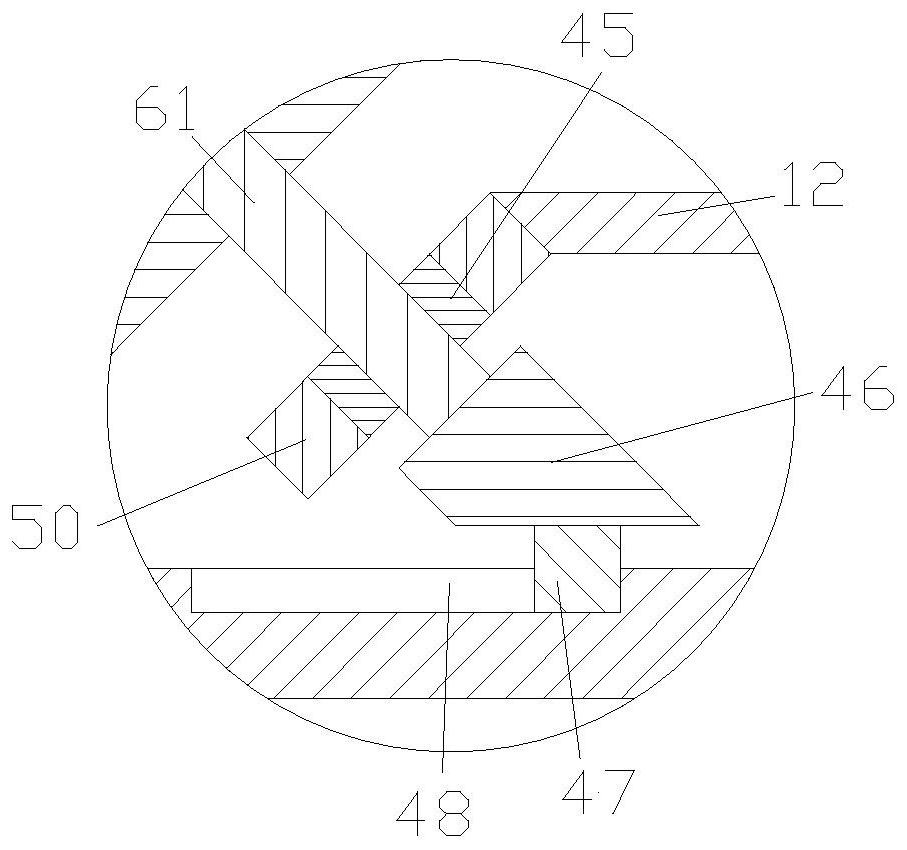

[0031] Refer to attached Figure 1-10: The butterfly valve of this all-forged steel wear-resistant and high-temperature-resistant material in the present embodiment includes a pipeline 27, a butterfly valve 19 is installed inside the pipeline 27, and a box body 1 is fixedly installed on the top of the pipeline 27, and the inside of the box body 1 There is a transmission chamber 2 and a working chamber 62 below the transmission chamber 2. The top of the butterfly valve 19 is provided with a first rotating shaft 18 passing through the pipeline 27 and the bottom of the working chamber 62. The top of the first rotating shaft 18 is fixedly installed with a The first bevel gear 20 inside the cavity 62, the inside of the working cavity 62 is provided with a return-shaped frame 26, the bottom of the return-shaped frame 26 is fixedly installed with a first guide block 25, and the bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com