A Stamping Die and a Method for Testing Its Strain Forming Capability

A stamping die and capability technology, applied in the field of stamping die and strain forming capability testing, can solve problems such as inability to detect material properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

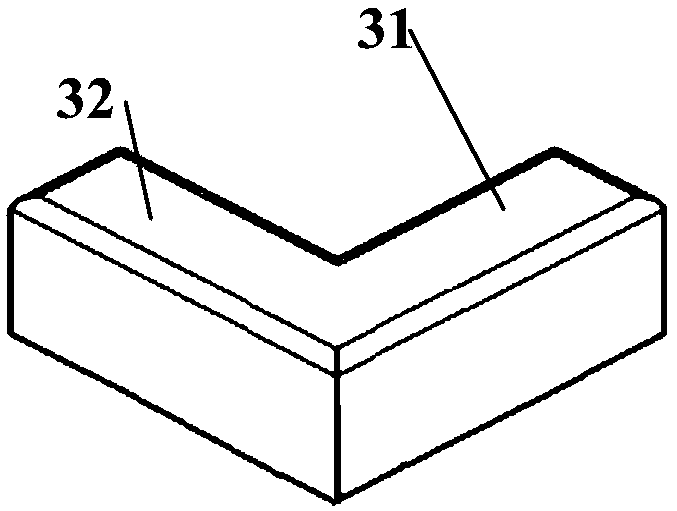

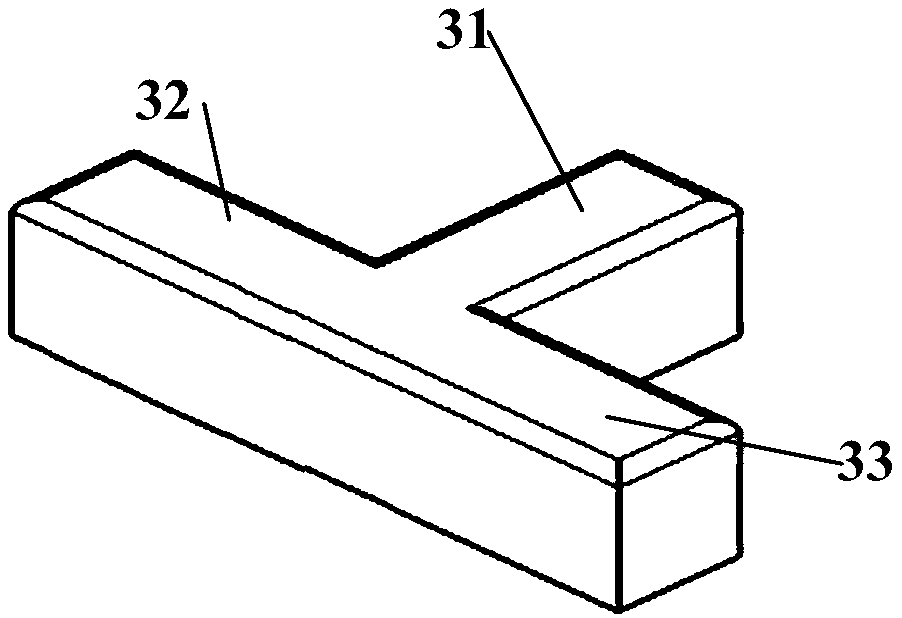

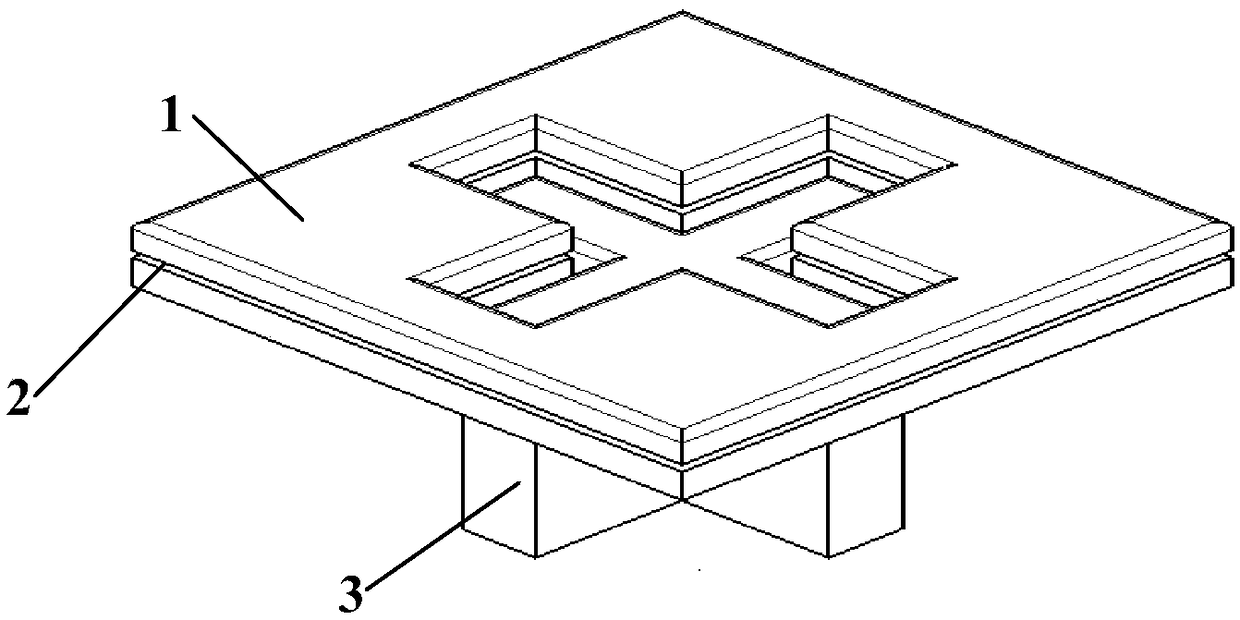

[0032] Such as Figure 1 to Figure 4 As shown, the embodiment of the present invention provides a stamping die, including: a die 1 , a blank holder 2 arranged on the die 1 , and a punch 3 matched with the die 1 .

[0033] Wherein, the concave mold 1 is also called the cavity, which is the main part of the outer surface of the molded plastic part. The concave mold 1 can be installed on the fixed mold or on the movable mold.

[0034] The blank holder 2 is arranged on the die 1 , and a ring-shaped pressing device is arranged on the edge part between the die 1 and the punch 3 . During the stamping process, the main function of the blank holder 2 is to prevent the edge of the workpiece from wrinkling due to instability.

[0035] The punch 3 is also called a punching needle, a punch, a male die, an upper die, etc., and is mainly used to form parts on the inner surface of the product. Wherein, the shape of the punch 3 matches the shape of the die 1 . Since the strain states of dif...

Embodiment 2

[0040] The first embodiment above introduces the stamping die of the present invention, and the following embodiment will further introduce and explain the method of strain forming ability detection using the stamping die in combination with the accompanying drawings and specific application scenarios.

[0041] Specifically, as Figure 5 As shown, the method for detecting the strain forming ability comprises the following steps:

[0042] Step 501: Stamping the board to be tested through a stamping die.

[0043]Wherein, the stamping die includes: a die, a blank holder arranged on the die, and a punch matched with the die; wherein, the punch at least includes a first punching end face and a second punching end face connected to each other, the first The first stamping end surface and the second stamping end surface intersect each other to form a first angle. In the production and manufacture of automobiles, 60%-70% of metal parts need to be plastically formed. Stamping is an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com