Offshore and intertidal-zone amphibious wind electricity operation and maintenance trimaran

An intertidal zone and wind power technology, applied in the field of amphibious three-body wind power operation and maintenance ships in the offshore intertidal zone, can solve problems such as poor stability and seakeeping, relatively large problems in operability and work efficiency, and increased difficulty. Improve stability and speed, facilitate wind power maintenance work, and reduce its own weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

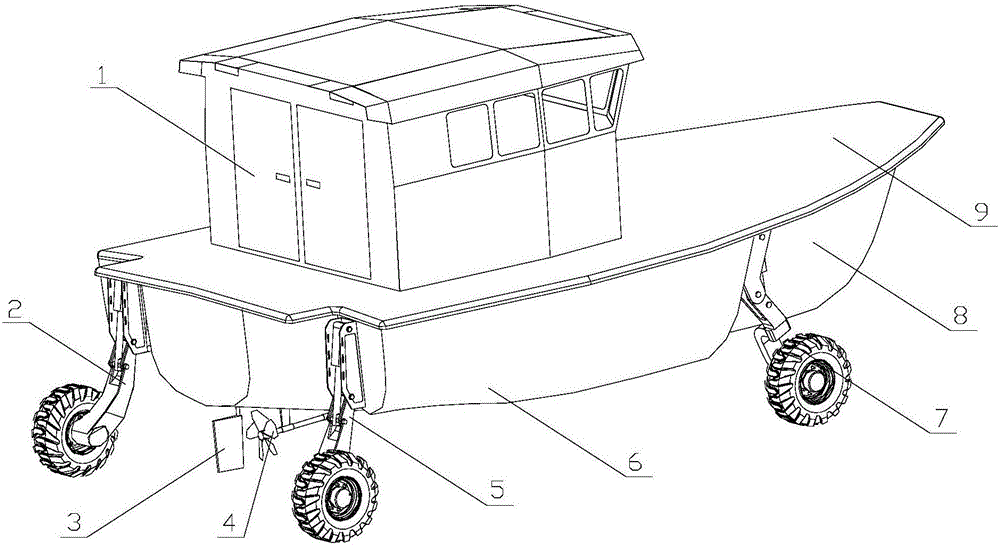

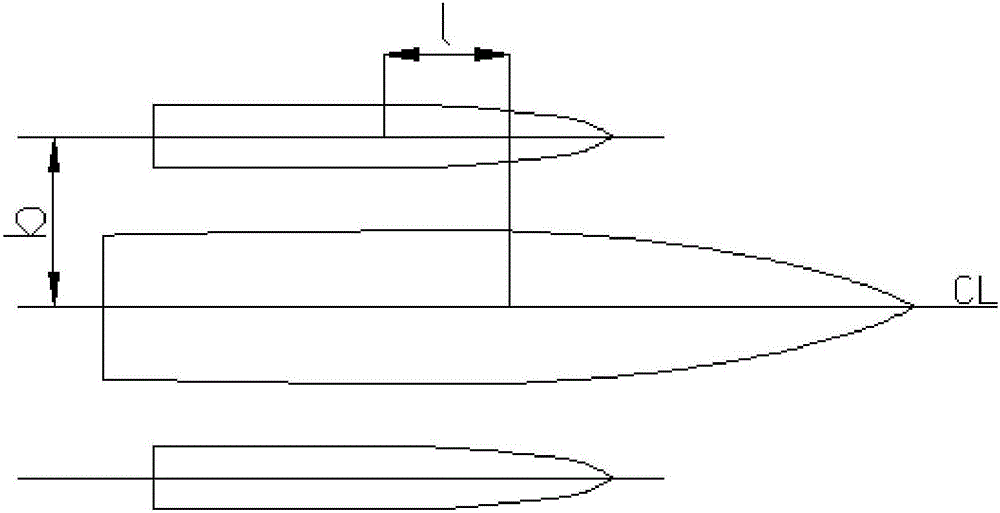

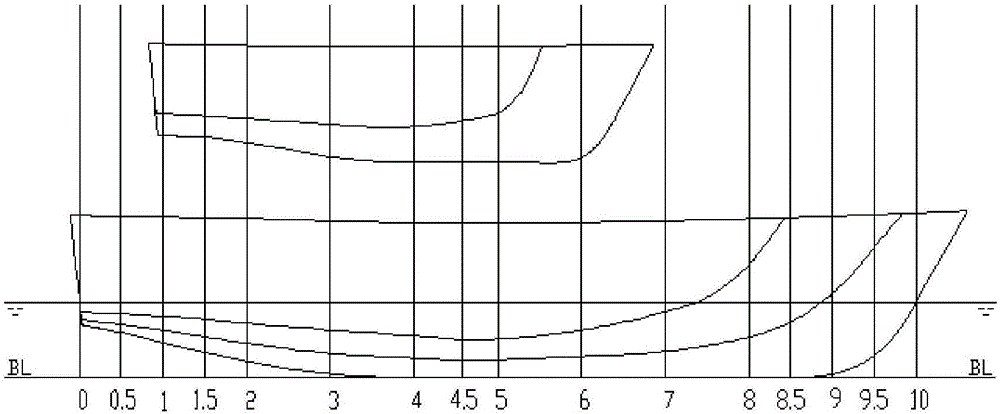

[0026] like Figure 1 to Figure 7 As shown, an amphibious trimaran wind power operation and maintenance ship in the intertidal zone of the present invention comprises an amphibious trimaran side body 6 and an amphibious trimaran superstructure 1 located above the amphibious trimaran side body 6, the structure The main hull is a three-body structure, consisting of a main body 8 and two side bodies 6 distributed on both sides. 6 is located at the middle rear of the main body 8, the side body 6 accounts for 10% of the displacement of the main body 8, the horizontal distance between the main body 8 and the side body 6 is 2 meters, and the longitudinal distance is 1.28 meters. Both sides of the front end of the amphibious trimaran side body 6 are provided with a left front wheel and a right front wheel, and the left front wheel and the right front wheel are provided with a front wheel retractable system 7, and the amphibious trimaran side body 6 Rear left rear wheel and right rear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com