Plate spring and compressor

A technology of plate springs and substrates, applied in the direction of springs, springs/shock absorbers, leaf springs, etc., can solve problems such as the inability to freely adjust the width and gap of elastic arms, and achieve high natural frequency, low equivalent mass, and high stiffness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

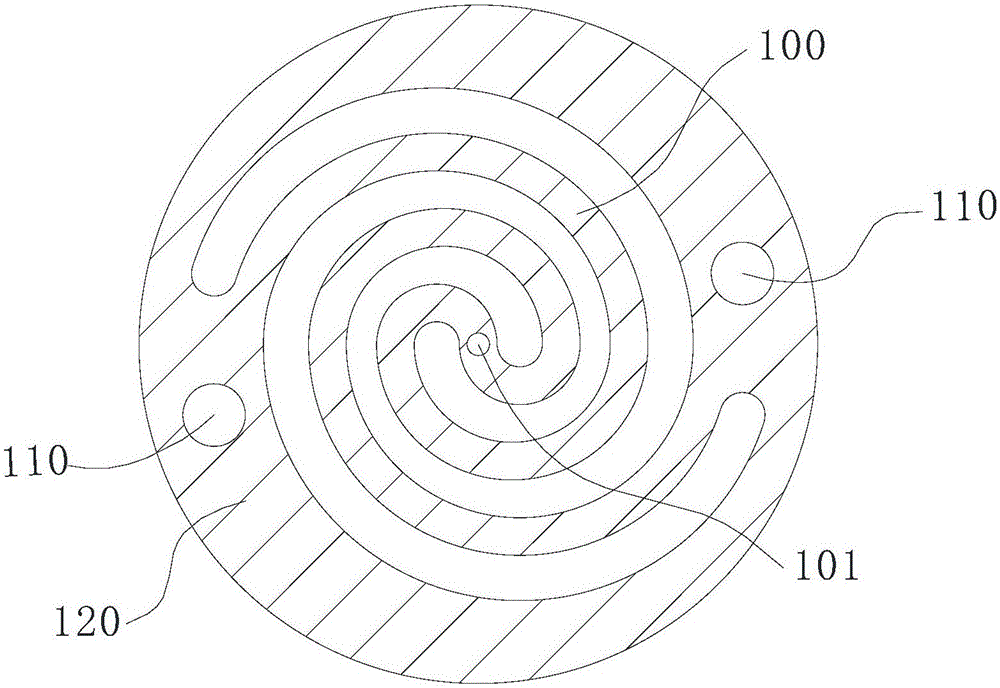

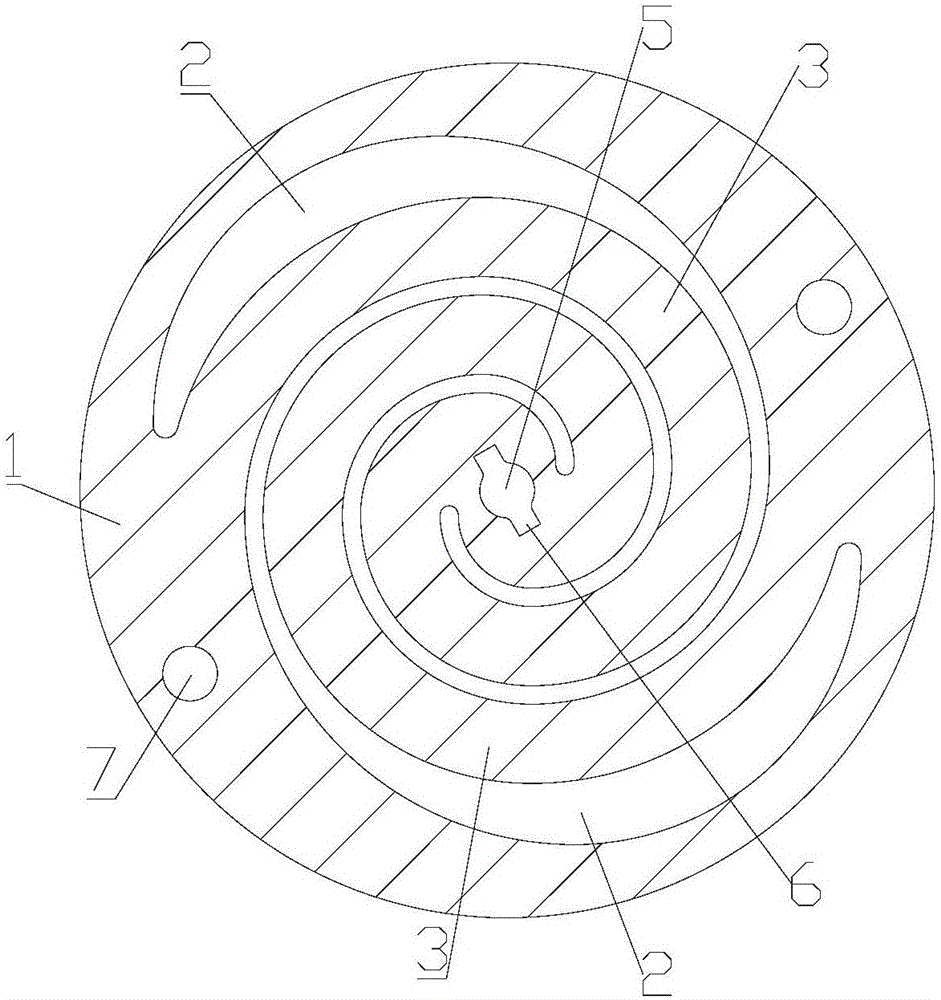

[0036] like Figure 2 to Figure 8 As shown, the leaf spring in the present invention includes a base plate 1, and at least two openings 2 extending in a spiral shape are formed on the base plate 1, so that an elastic arm 3 can be formed at a part between two adjacent openings 2, Therefore, the number of elastic arms 3 is related to the number of openings 2 , if there are two openings 2 , two elastic arms 3 are formed. Preferably, each elastic arm 3 has the same structure. Preferably, the number of elastic arms is two or three.

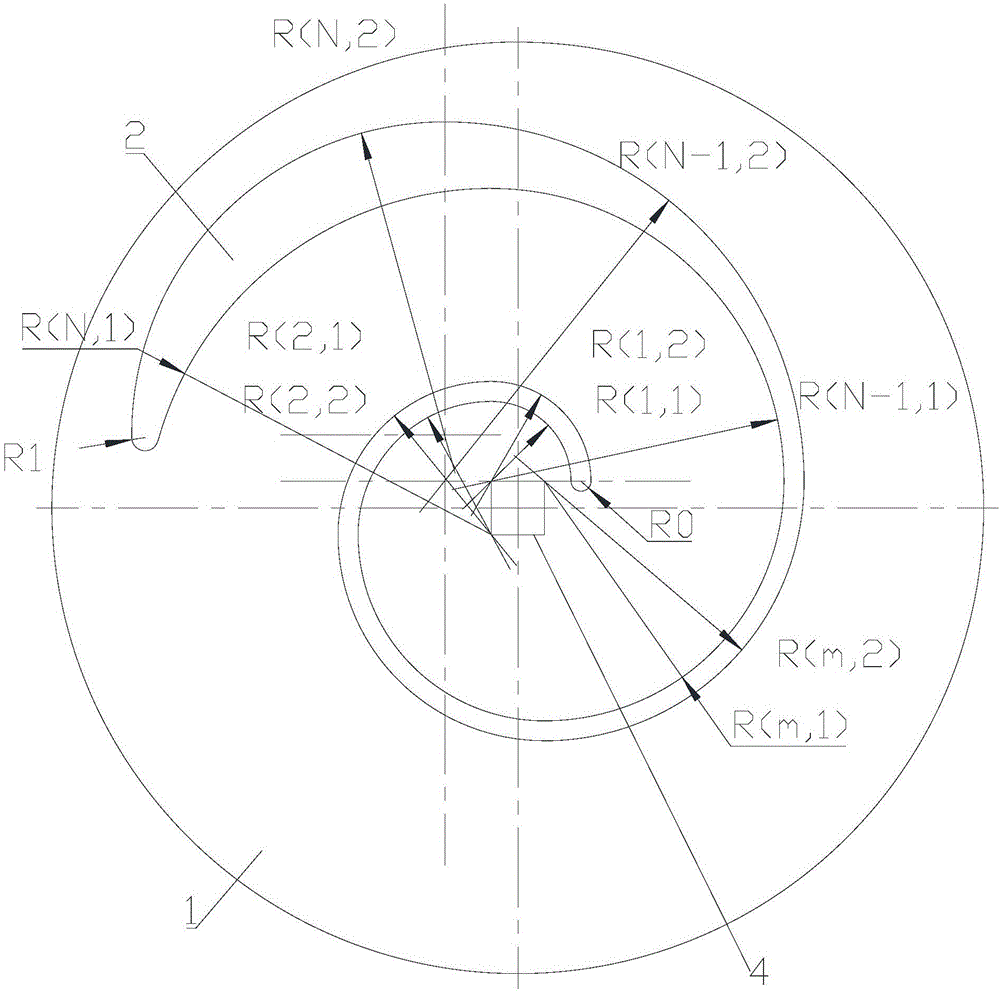

[0037] Different from the methods in the prior art, the opening 2-shaped line in the present invention is generated by using a reference polygon 4, which can be a regular polygon or a non-regular polygon. Wherein, each op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com