Storehouse fullness acousto-optical reminding device for grain storage storehouse of combined harvester

A technology for combine harvesters and storage bins, applied to harvesters, measuring devices, lubrication indicator devices, etc., can solve problems such as waste, prone to safety accidents, distracting drivers, etc., and achieve the effect of avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

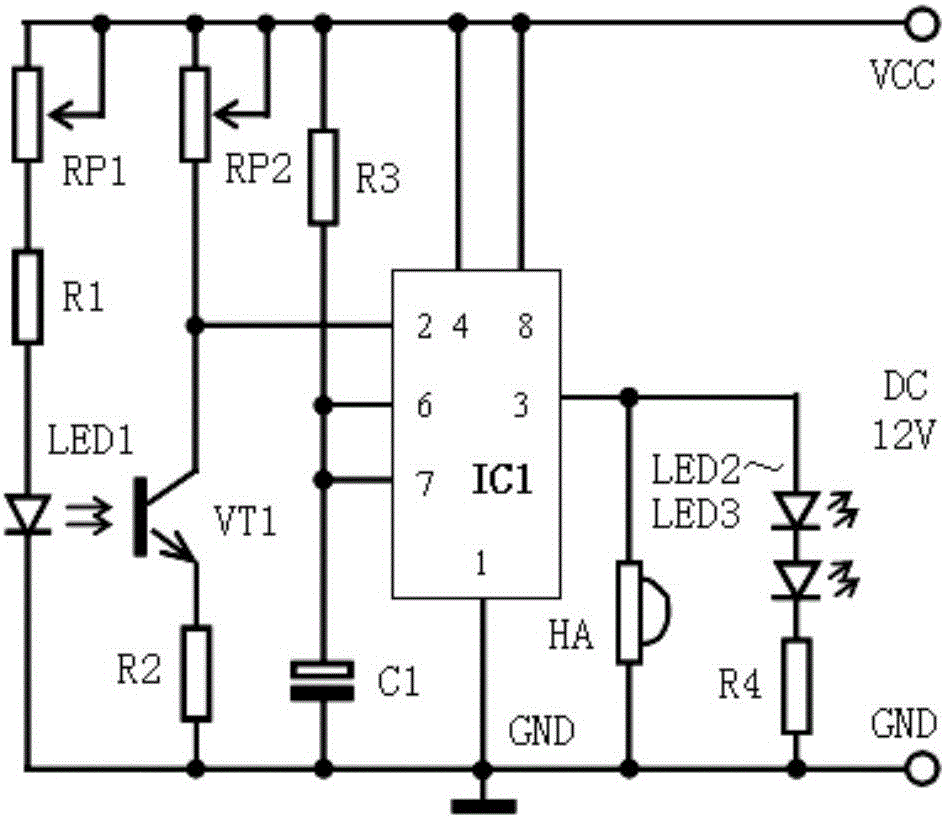

[0015] According to attached figure 1 The working principle diagram of the acousto-optic warning device circuit for the grain storage bin of the combine harvester shown and the description of the drawings, and the connection relationship between the components in each part of the circuit described in the summary of the invention, and the components described in the implementation mode The present invention can be realized by implementing the device technical parameter requirements and the key points of circuit fabrication. The related technologies of the present invention will be further described below in conjunction with the embodiments.

[0016] Component names and main technical parameter list

[0017] Part number

Component name

technical parameter

quantity

illustrate

IC1

Time base circuit

NE555, package form DIP

1

8 pins

LED1

¢5, HG505 type

1

VT1

infrared photot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com