Processing method of tooth cleaning brush head

A processing method and brush head technology, which is applied in the field of toothbrush manufacturing, can solve problems such as tooth surface damage and poor tooth cleaning effect, and achieve the effects of eliminating edges and corners, strong brushing force, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

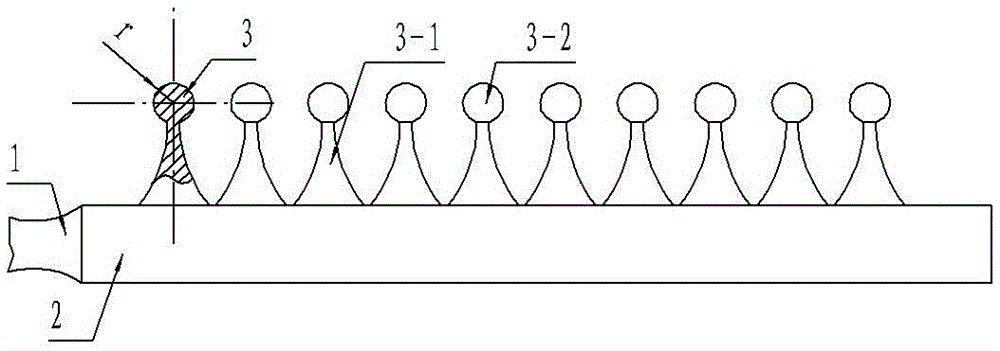

[0010] The processing method of this tooth-cleaning brush head comprises processing a kind of tooth-cleaning brush head, and this tooth-cleaning brush head is as figure 1 As shown, it includes the bristles 3 erected on the brush base 2, and the connection part 1 connected to the handle at one end of the brush base 2. The bristles include the lower brush body 3-1 and the brush body 3-1 connected to the brush base 2. Brush ball at the top 3-2. The brush ball 3-2 is a solid ball, which makes the bristles 3 have a stronger brushing force on the teeth, and at the same time eliminates the edges and corners of the top surface of the traditional bristles, and avoids damage to the teeth after long-term use; the radius of the brush ball 3-2 r= 0.2mm . The brush body 3-1 is a truncated cone with a large bottom and a small top, and the conical surface of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com