Filter for injection syringe and injection syringe

A syringe and filter technology, which is applied in the field of medical devices, can solve the problems of difficulty in sorting and recycling syringes, and the syringes have no filtering function and cannot be disassembled.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

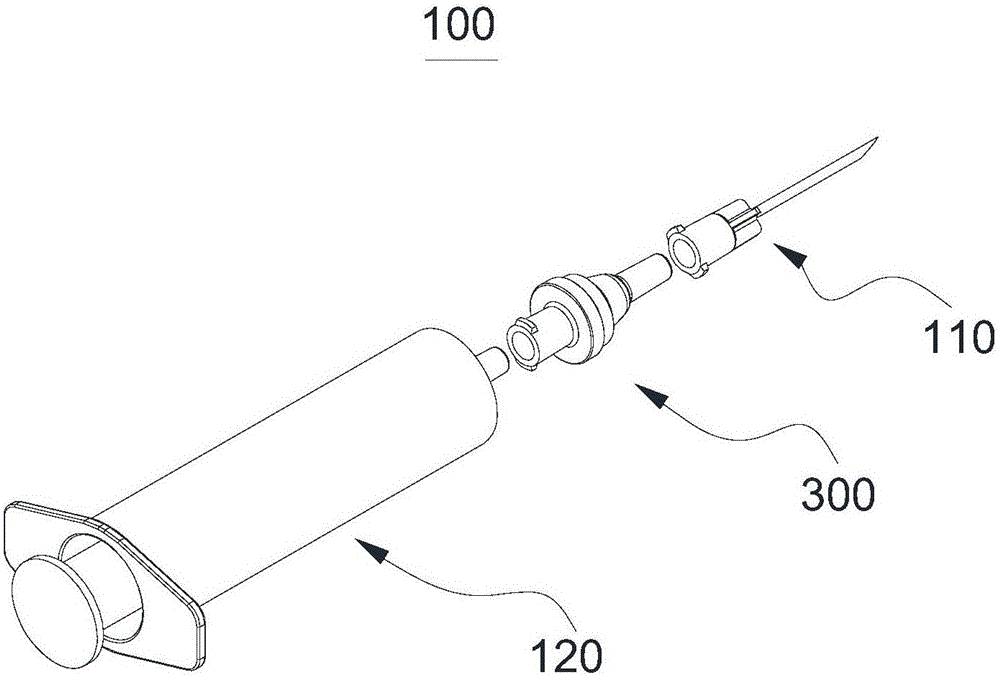

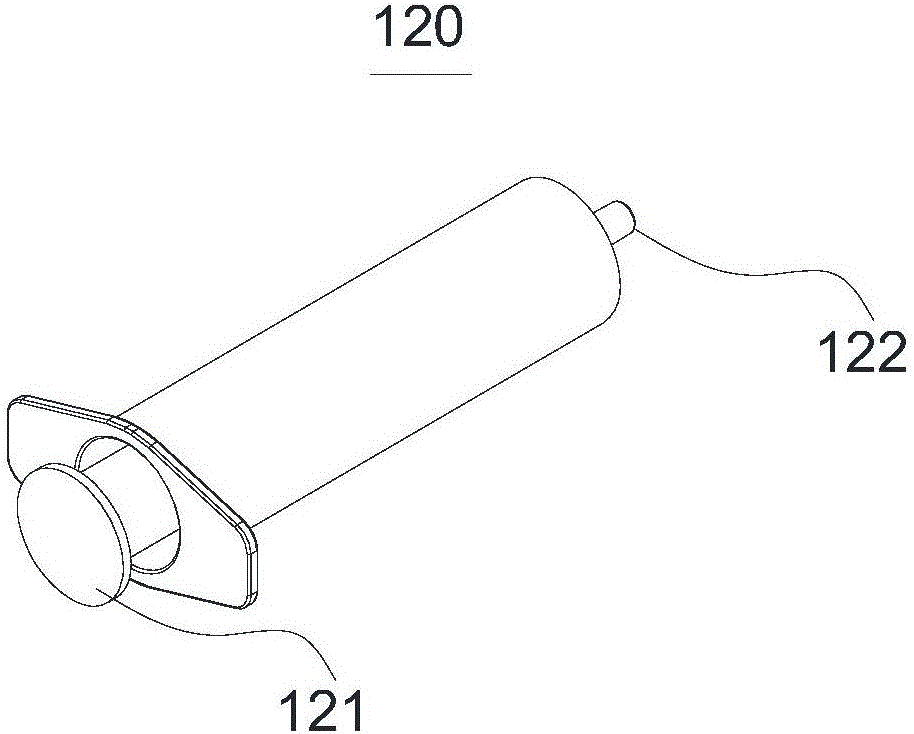

[0041] Such as figure 1 As shown, the syringe 100 includes a needle 110 , a barrel 120 and a syringe filter 300 . The opposite ends of the syringe filter 300 are detachably connected to the needle 110 and the syringe 120 respectively.

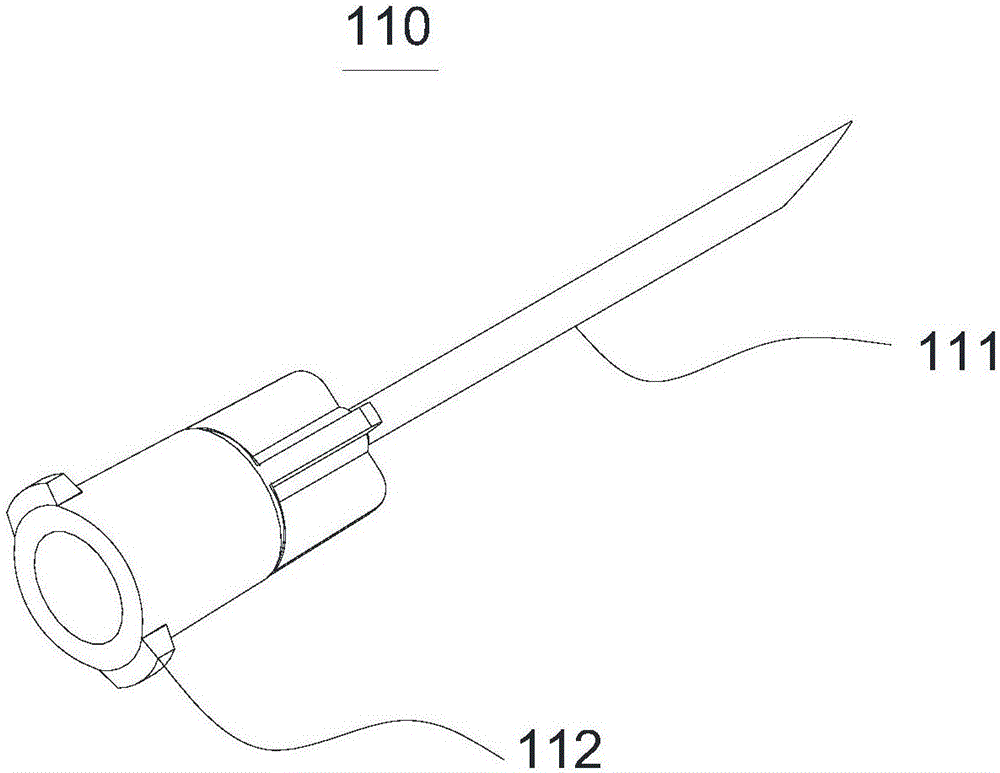

[0042] Such as figure 1 and figure 2 As shown, the needle 110 is sleeved on the syringe filter 300, the needle 110 is hollow, and the end of the needle 110 away from the syringe filter 300 is provided with a needle tube 111, and the needle tube 111 communicates with the syringe filter 300 through the hollow part of the needle 110.

[0043] The outer wall of the needle 110 is provided with first protrusions 112 , and the number of the first protrusions 112 is two, which are respectively arranged opposite to the outer wall of the end of the needle 110 away from the needle tube 111 . The first protrusion 112 acts as a force application point when the needle 110 is installed on the syringe filter 300 , making the installation operation more con...

no. 2 example

[0065] The syringe filter 400 provided by the embodiment of the present invention has the same realization principle and technical effects as the first embodiment. For a brief description, for the parts not mentioned in this embodiment, you can refer to the corresponding content in the first embodiment. .

[0066]Such as Figure 11 and 12 As shown, the end of the second liquid outlet chamber 421 away from the elastic non-return member 410 is provided with a second filter membrane 440 , and the second filter membrane 440 completely covers the opening of the second liquid outlet chamber 421 away from the elastic non-return member 410 .

[0067] When the liquid medicine is sucked, the liquid inlet 416 is opened, and the liquid enters the liquid inlet chamber 428, enters the liquid inlet hole 422 through the liquid inlet chamber 428, and finally enters the syringe. When the medicinal liquid is pushed out, the medicinal liquid reaches the second filter membrane 440 from the syrin...

no. 3 example

[0071] The syringe filter 500 provided by the embodiment of the present invention has the same realization principle and technical effect as the first embodiment. For a brief description, for the parts not mentioned in this embodiment, you can refer to the corresponding content in the first embodiment. .

[0072] Such as Figure 13-15 As shown, the first filter membrane 530 is arranged at the end of the plurality of liquid inlet holes 522 away from the elastic non-return member 510, and covers the openings of the plurality of liquid inlet holes 522, and the second filter membrane 540 is arranged at the second liquid outlet cavity 521 away from the elastic One end of the non-return member 510 covers the opening of the second liquid outlet cavity 521 , and the first filter membrane 530 and the second filter membrane 540 are integrally formed.

[0073] The advantage of the integral formation of the first filter membrane 530 and the second filter membrane 540 is that the producti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com