Integrated shoe moulding technology

A molding process, an integrated technology, applied in footwear, other home appliances, home appliances, etc., can solve the problems of shoes cracking, sutures easy to wear, fall off, etc., to prevent mold burns, low product defective rate, improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0032] The molding process of the one-piece shoe provided by this embodiment includes the following steps:

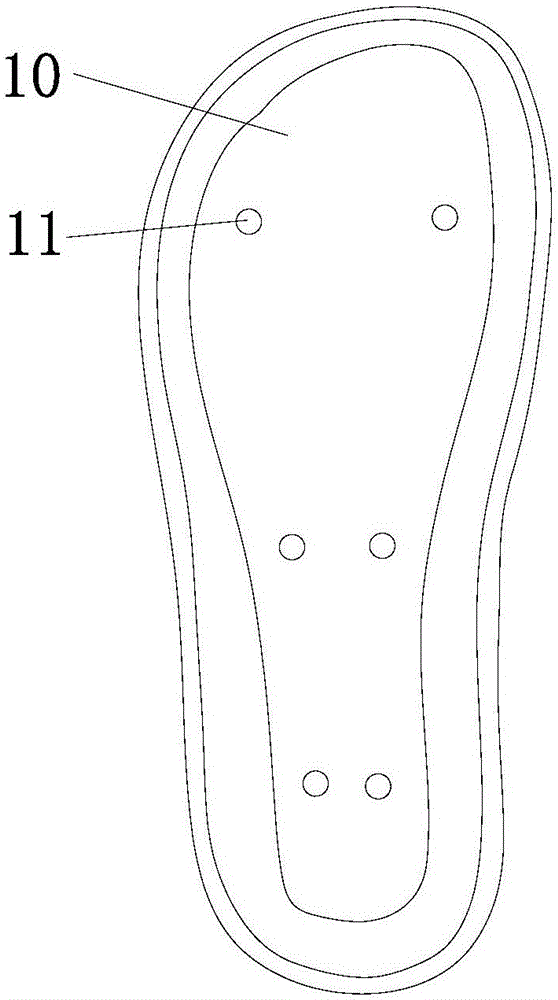

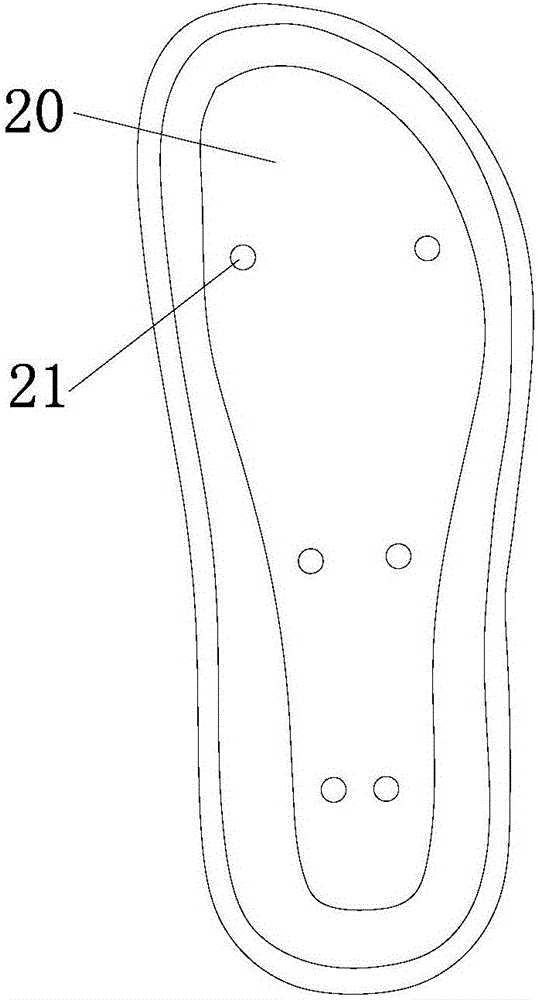

[0033] S1. According to the style of shoes, respectively obtain matching upper cold mold blanks, middle cold mold blanks and lower cold mold blanks by injection molding. The specific injection molding method is a conventional one-shot molding method, which is not the focus of this embodiment. No more details here. The upper cooling mold blank, the middle cooling mold blank and the lower cooling mold blank are preferably made of EVA material, and the specific shapes of the upper cooling mold blank, the middle cooling mold blank and the lower cooling mold blank need to be determined according to the shape of the one-piece shoe to be formed, In this embodiment, the one-piece shoes to be obtained are sandals or slippers, and the upper, midd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com