Intelligent Conveyor System

An intelligent conveying and conveyor belt technology, applied in the field of robotics, can solve the problems of small working range, working dead angle, slow handling speed, etc., and achieve the effects of accurate mobile positioning, large working range and strong snatch ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

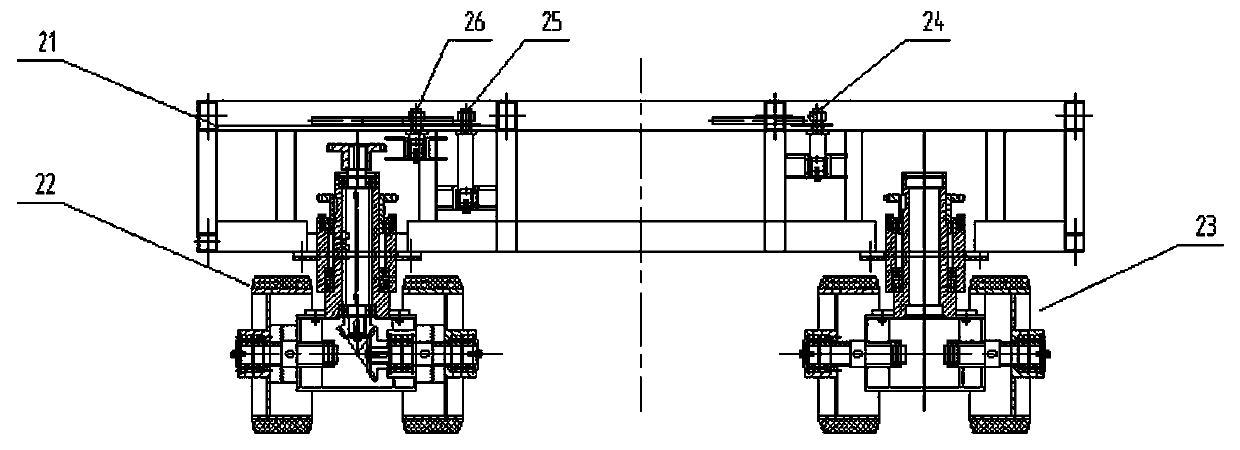

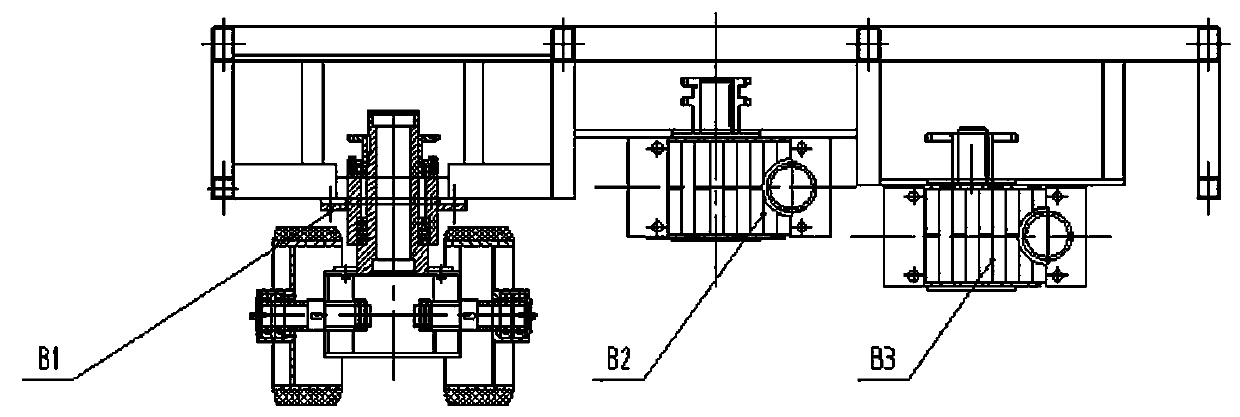

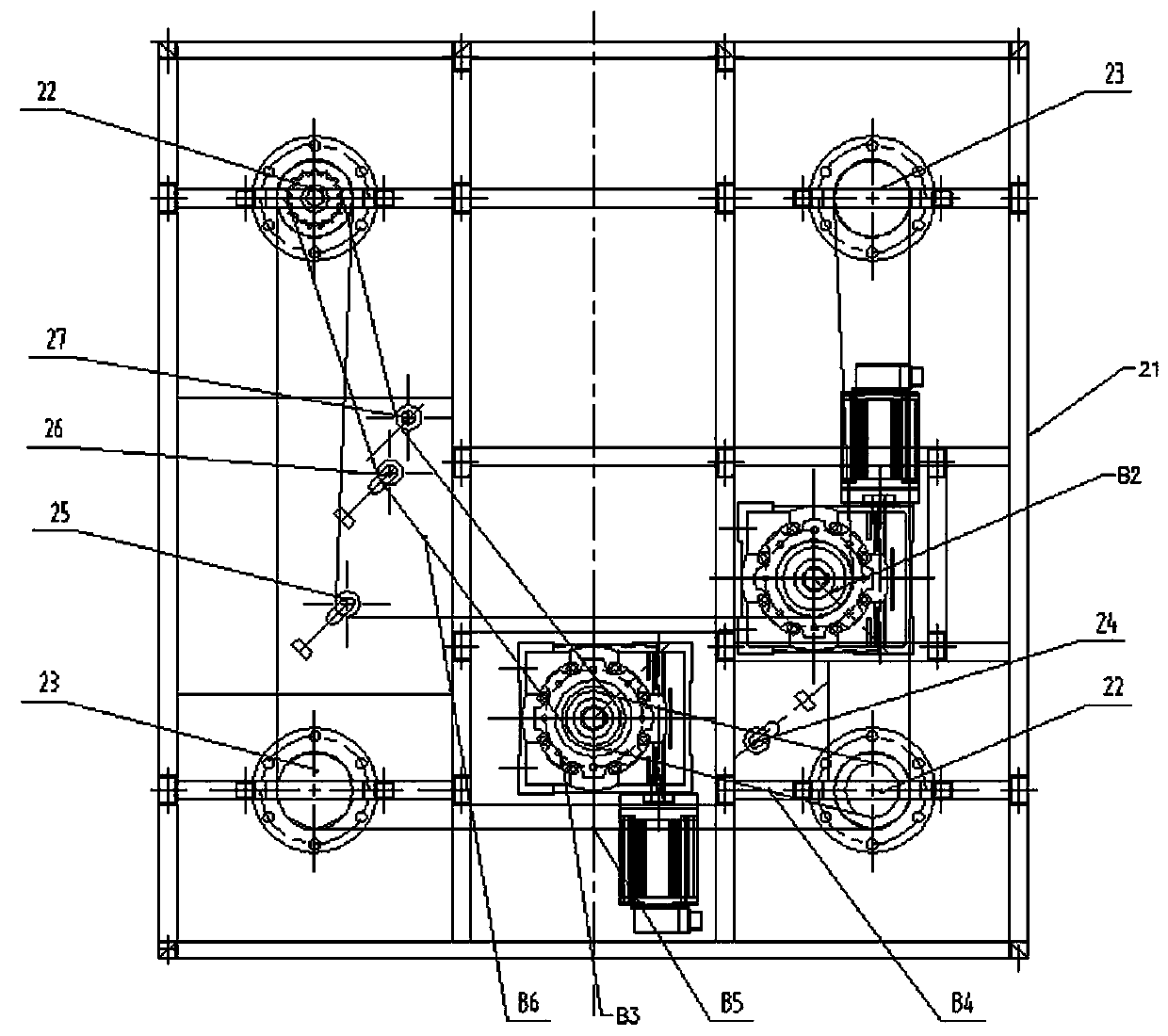

[0062] Examples such as figure 1 , figure 2 , image 3 , Figure 8 As shown, the intelligent conveying system includes a conveyor belt 12a,

[0063] It also includes a handling manipulator 29 for transporting goods on the conveyor belt. The handling manipulator 29 is connected to the moving seat 28, and the moving seat 28 can drive the handling manipulator 29 to move.

[0064] Described mobile base 28 comprises chassis 21, and chassis 21 bottoms are rotatably connected with two main driving wheels 22 and two driven wheels 23, and the connecting line between two main driving wheels 22 axes and the line between two driven wheels 23 axes Connection crossing settings between.

[0065] The chassis 21 is provided with a second reduction motor B3 for driving the main transmission wheel 22 to walk, the second reduction motor B3 is connected to one of the main transmission wheels 22 through the first chain B4, and the second reduction motor B3 is connected through the third chain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com