Measuring device and method for liquid permeability of compressed rock in reservoir conditions

A liquid permeability and tight rock technology, which is applied in development experiments and oil and gas field exploration, can solve problems such as difficult to judge the steady state, long stable time in tight rock permeability testing, and difficult micro-flow measurement, so as to achieve reliable and good test results. The effect of applying the foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0020] Example 1

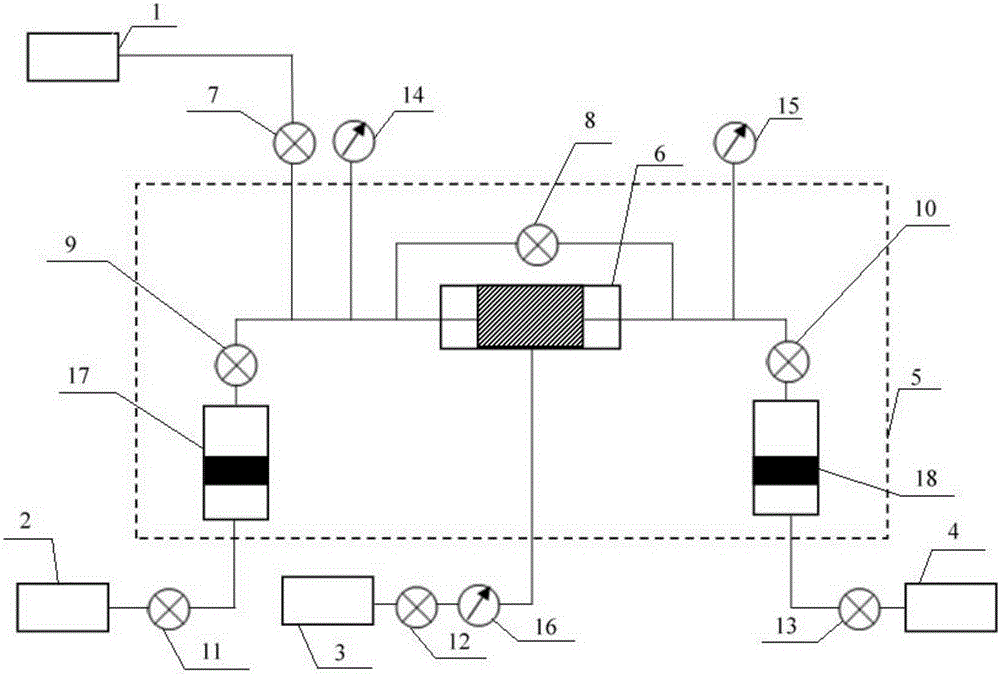

[0021] like figure 1 As shown, a device for measuring liquid permeability of tight rocks under reservoir conditions according to a specific embodiment of the present invention includes a constant temperature box 5, a first piston container 17, a second piston container 18, a core holder 6, a surrounding Pressure pump 3, vacuum pump 1, injection pump 2 and back pressure pump 4. Wherein the first piston container 17 and the second piston container 18 are in the incubator 5, and the first piston container 17 and the second piston container 18 are used to contain test fluid. The rock core holder 6 is also arranged in the thermostat 5, and the inside of the rock core holder 6 is used to clamp the rock core sample. Liquid end connection. The temperature of the constant temperature box 5 of the present embodiment can be set, and during specific measurement, it is ensured that the rock core sample in the rock core holder 6 and the test fluid in the first piston c...

Example Embodiment

[0032] Example 2

[0033] A method for measuring the fluid permeability of tight rocks under a reservoir condition according to a specific embodiment of the present invention, comprising the following steps (combined with figure 1 Be explained):

[0034] (1) select the rock core sample for experiment and pack the rock core sample into the rock core holder 6;

[0035] (2) Utilize the confining pressure pump 3 to add the confining pressure to the initial value for the rock core sample;

[0036] (3) Utilize the vacuum pump 1 to vacuumize both sides of the rock core sample;

[0037] (4) Utilize the flow pump to apply the same pressure on both sides of the core sample, and set the confining pressure pump 3 to the tracking mode at the same time, so that the loaded confining pressure is always 3MPa greater than the fluid pressure. perform fluid saturation;

[0038] (5) Increase the pressure applied to both sides of the core sample to the reservoir pressure, repeat the fluid satur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com