Cutting fluid foam performance testing device

A testing device and cutting fluid technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of large differences in simulation scenarios and unrepresentative test results, etc., to achieve foam performance test preparation, test results are true and reliable, and convenient The effect of turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below by means of specific embodiments and reference numerals:

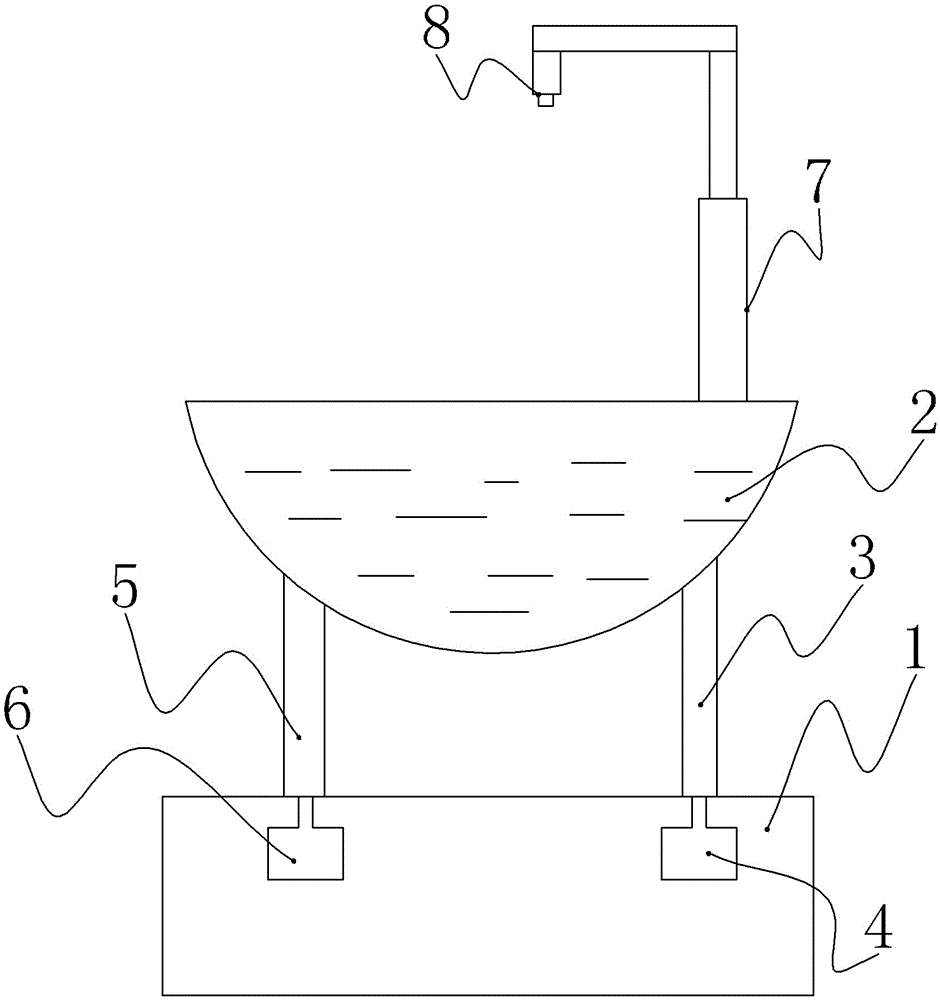

[0013] The reference signs in the drawings of the description include: base 1 , housing box 2 , first support rod 3 , first air cylinder 4 , second support rod 5 , second air cylinder 6 , delivery pipe 7 , and drain port 8 .

[0014] The embodiment is basically as attached figure 1 Shown: including the base 1, the base 1 is equipped with a transparent storage box 2 with an open top, the bottom of the storage box 2 is arc-shaped, a liquid pump is installed in the storage box 2, and a vertical delivery pipe 7 is connected to the liquid pump , the top of the delivery pipe 7 is provided with a drain port 8, a switch is installed at the drain port 8, and the drain port 8 is located directly above the opening of the storage box 2. The bottom of the housing box 2 is installed with a vertical first support rod 3 and a second support rod 5, both of which ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com