Test method for slag production amount and deformation of drilling hole of high-gas soft coal

A test method and gas technology, applied in the direction of volume measurement instrument/method, fuel test, capacity measurement calibration, etc., to achieve the effect of accurate test method, simple operation and reliable test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

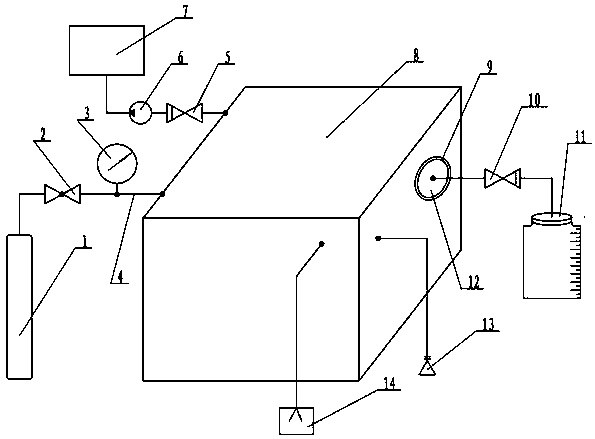

[0038] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0039] The idea of the present invention is to use the volume change of the fluid in the borehole as the measurement data of the borehole deformation, and to form a high-gassy soft coal body with a certain depth and diameter by preparing a sample of the soft coal body containing high gas and then drilling along the bed. Drilling, according to the deformation of high-gas soft coal samples under external loads, the dynamic variation law of drilling deformation and slag production in high-gas soft coal with gas content and gas pressure of soft coal is obtained.

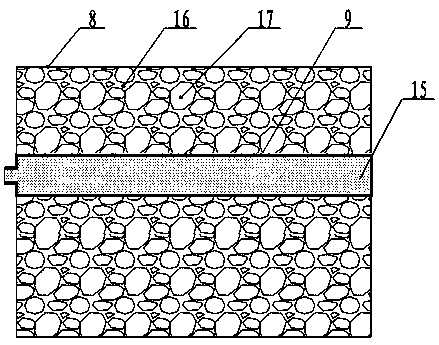

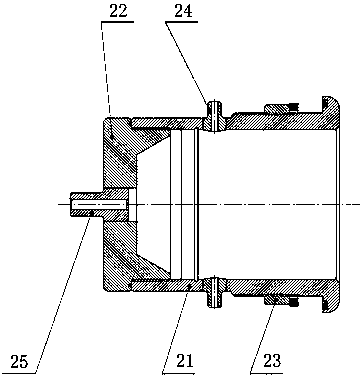

[0040] The test device used in the present invention is as figure 1 and figure 2 Shown: including reactor, drilling deformation simulator, water storage control and adjustment device, drainage measurement device and confining pressure control and adjustment device;

[0041] The reactor includes a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com