An on-line detection method for rolling direction offset of hot rolling mill rolls

A technology of rolling direction and detection method, which is applied in the direction of metal rolling, metal rolling, length measuring device, etc., can solve the problems that the shape of the plate cannot be accurately controlled, the quality of the hot-rolled steel plate is troubled, and the rolling control is difficult. Accurate and reliable effect, high promotion and use value, simple and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

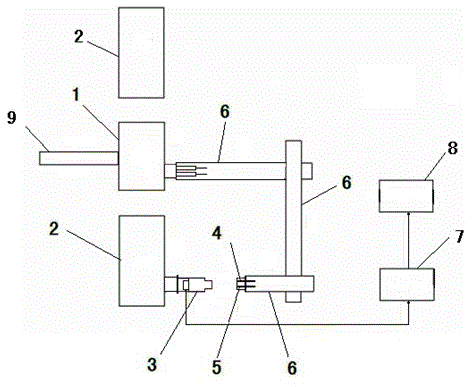

[0024] In the present invention, the archway of the hot rolling mill is used as a reference object, and the light intensity center of the light-permeable circular hole relatively stationary relative to the archway is used as the feature point of the archway position, and the position feature point of the archway is acquired by a CCD camera relatively stationary to the roll during the rolling process By comparing the image with the calibration distance, calculate the real-time physical coordinates of the center of the feature point of the archway, and determine the displacement of the camera lens relative to the rolling direction of the feature point of the archway, so as to obtain the offset of the roll relative to the archway in the rolling direction .

[0025] This approach takes the following steps in concrete implementation:

[0026] (1) Taking the rolling mill archway 2 as a reference object, set the light intensity center of a light-transmitting circular hole 4 that is r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com