Integrated retarder switch

A retarder, integrated technology, applied in electrical switches, electrical components, circuits, etc., can solve problems such as lack of safety and inconvenience, and achieve the effect of fast function switching, convenient operation process, and compact layout between structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

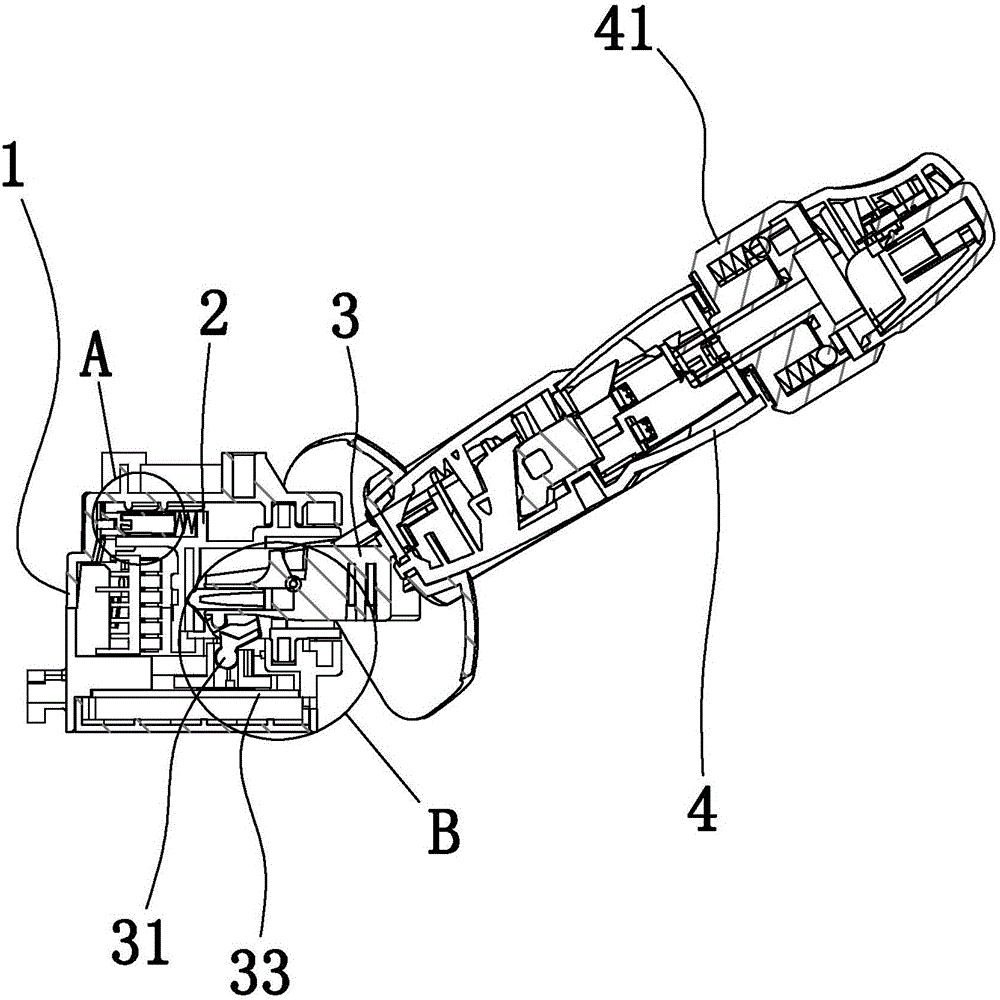

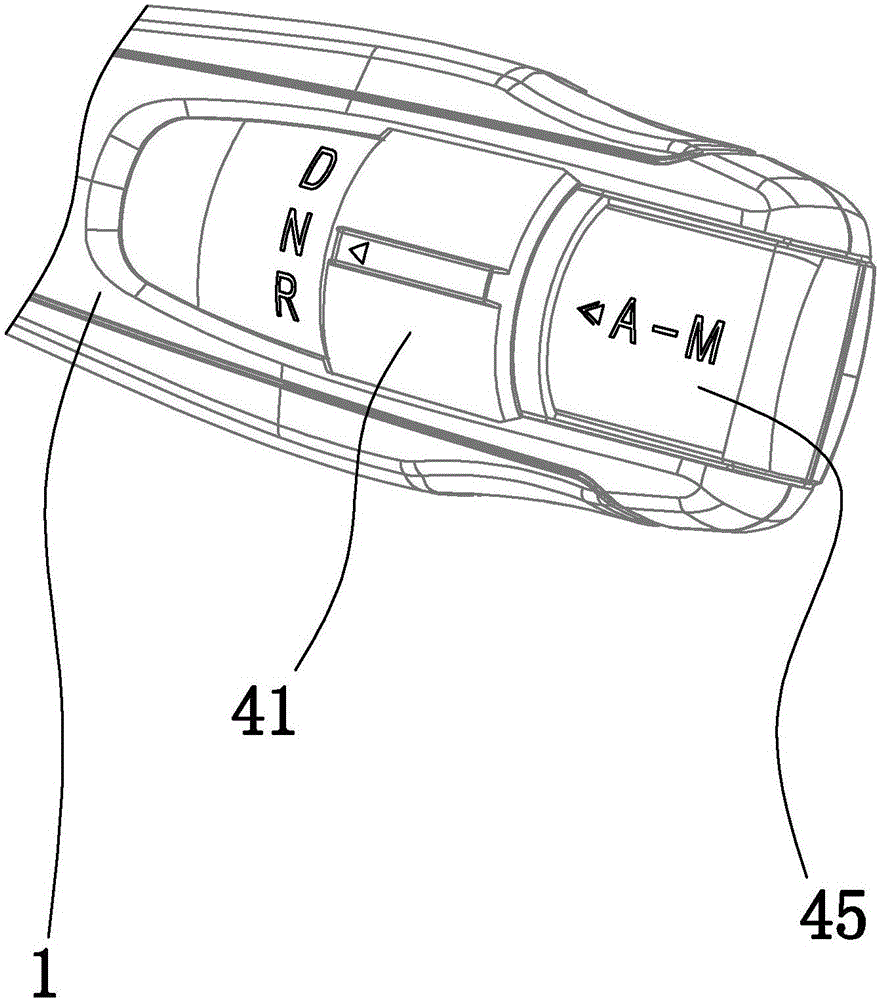

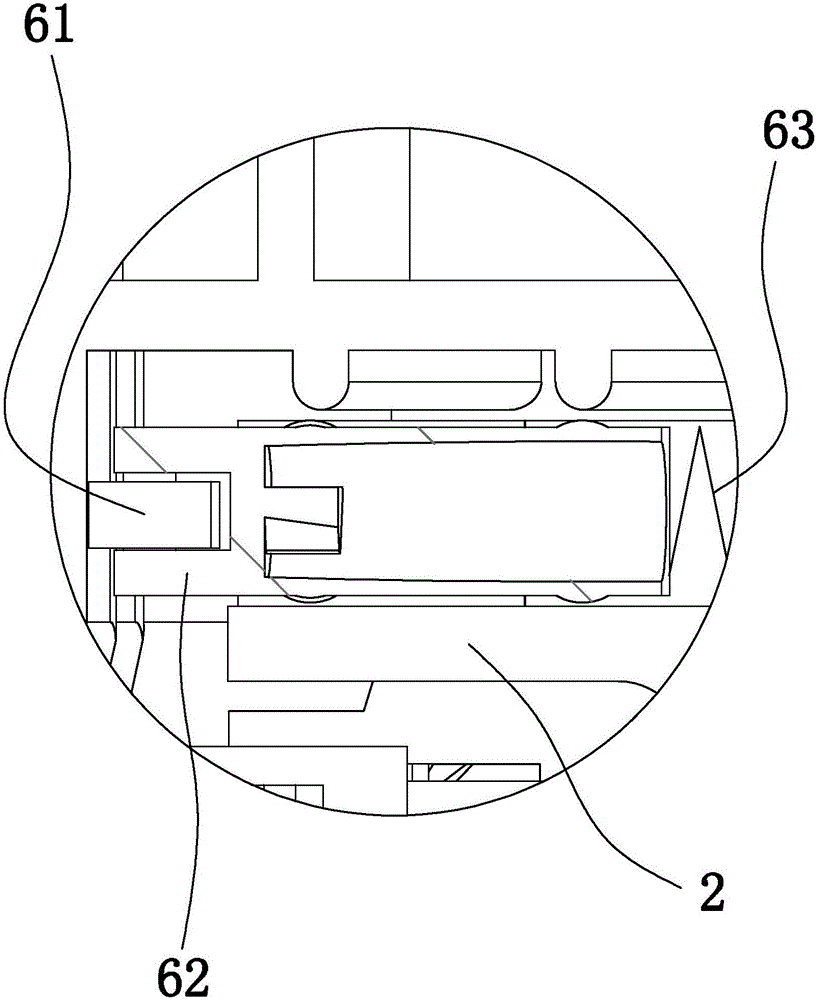

[0030] Such as Figure 1 to Figure 8 In the shown embodiment, an integrated retarder switch includes a housing base 1, a drive block 2 that can rotate relative to the housing base, and a retarder base 5 fixed to the housing base. The drive block and the retarder base The seats are all in the housing seat, and the retarder base is provided with a static contact part, a movable contact part and an elastic sheet for pushing the movable contact part to the static contact part, and the static contact part and the elastic sheet are connected to the retarder base , the moving contact part is set on the elastic sheet, and the driving block is provided with a retarding block for separating the static contact part from the moving contact part, and both the static contact part and the moving contact part are connected in the retarder circuit; when the sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com