Transmission with electric motor and switchable gear unit

A technology of transmission device and auxiliary reducer, which can be used in transportation and packaging, brakes, mechanical equipment, etc., can solve problems such as increased fuel consumption, and achieve the effect of improving driving power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

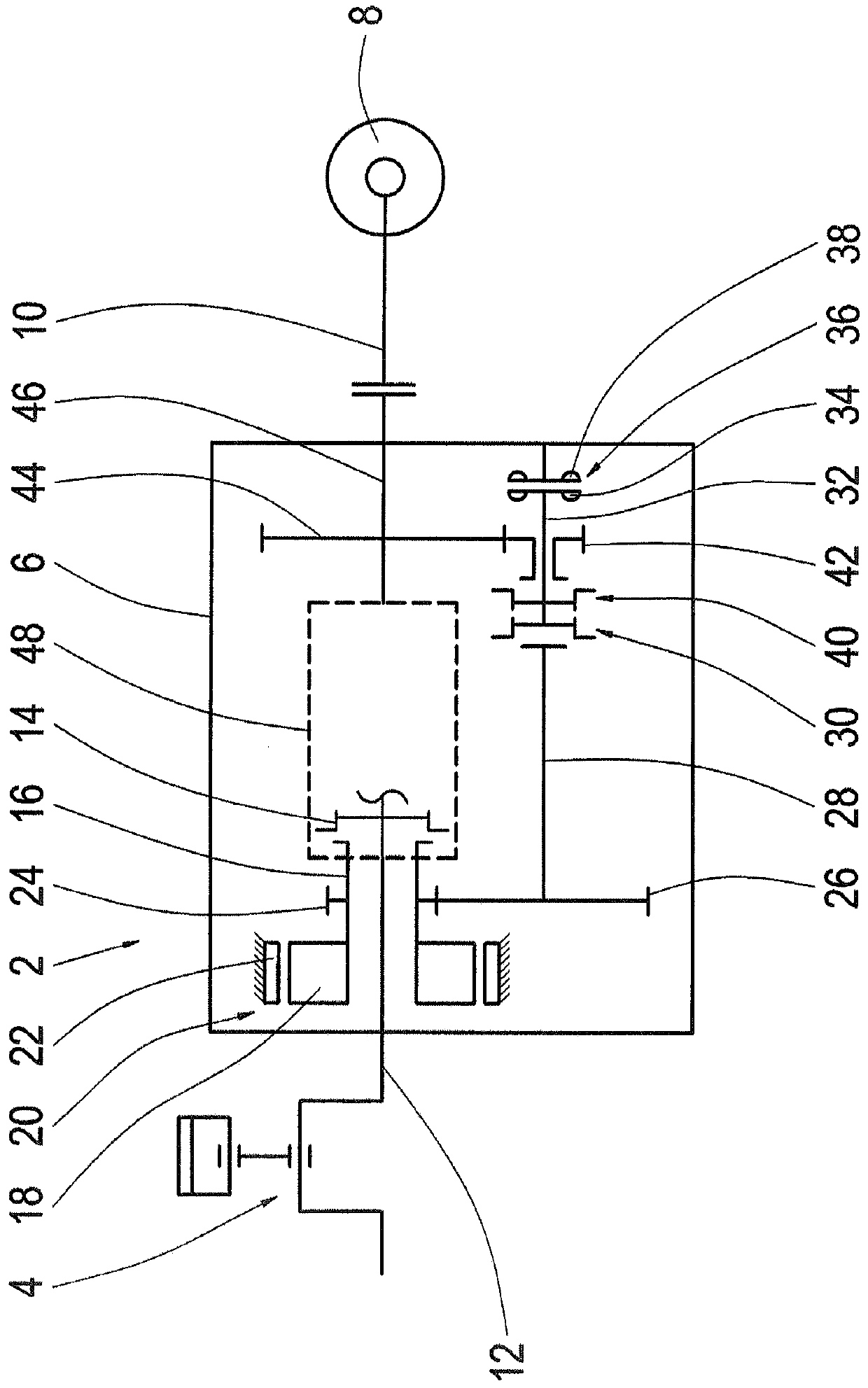

[0026] only figure 1 The drive train 2 of a vehicle, which is not shown in detail, is shown in a schematic illustration and includes a drive motor 4 , which is generally designed as an internal combustion engine, as well as a transmission 6 and a cardan shaft 10 connected to wheels 8 . A friction clutch, not shown here, can be provided between the drive engine and the transmission 6, in transmissions that do not otherwise implement the starting function of the vehicle and support during shifting processes within the transmission , the friction clutch is used to perform these functions. Into the transmission 6 an input shaft 12 is introduced, on which at least one component of the shift element 14 is arranged in a rotationally fixed manner. Arranged around the input shaft 12 in the form of a hollow shaft is a rotor shaft 16 which surrounds the input shaft 12 at the input of the transmission 6 . A rotor 18 of an electric machine 20 is arranged on the rotor shaft 16 . The roto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com