Intelligent-card groove milling device

A smart card and equipment technology, applied in milling machine equipment, details of milling machine equipment, metal processing equipment, etc., can solve the problems of restricting production efficiency, eye fatigue, increase in scrap rate, etc. The effect of reducing processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Hereinafter, the present invention will be further described in detail with reference to the examples and drawings, but the implementation of the present invention is not limited thereto.

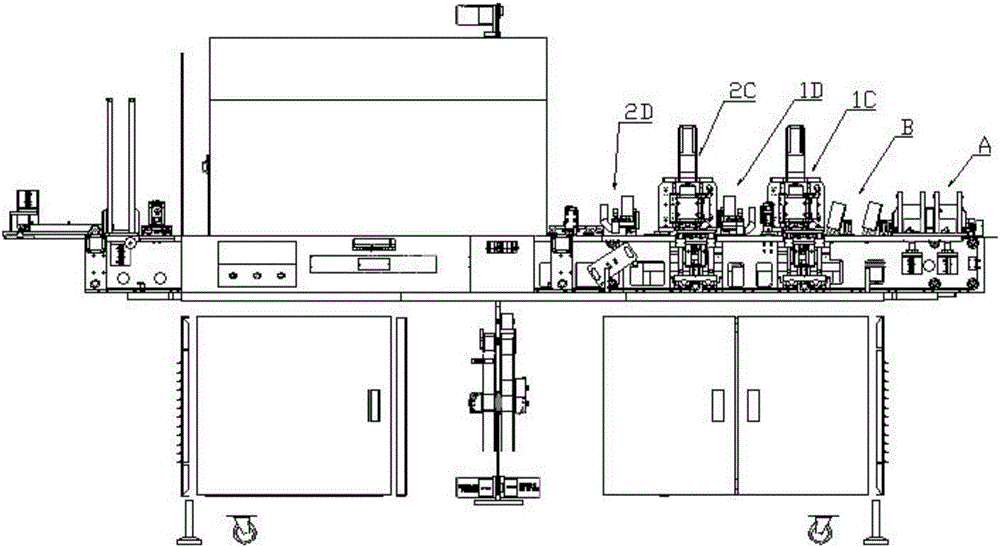

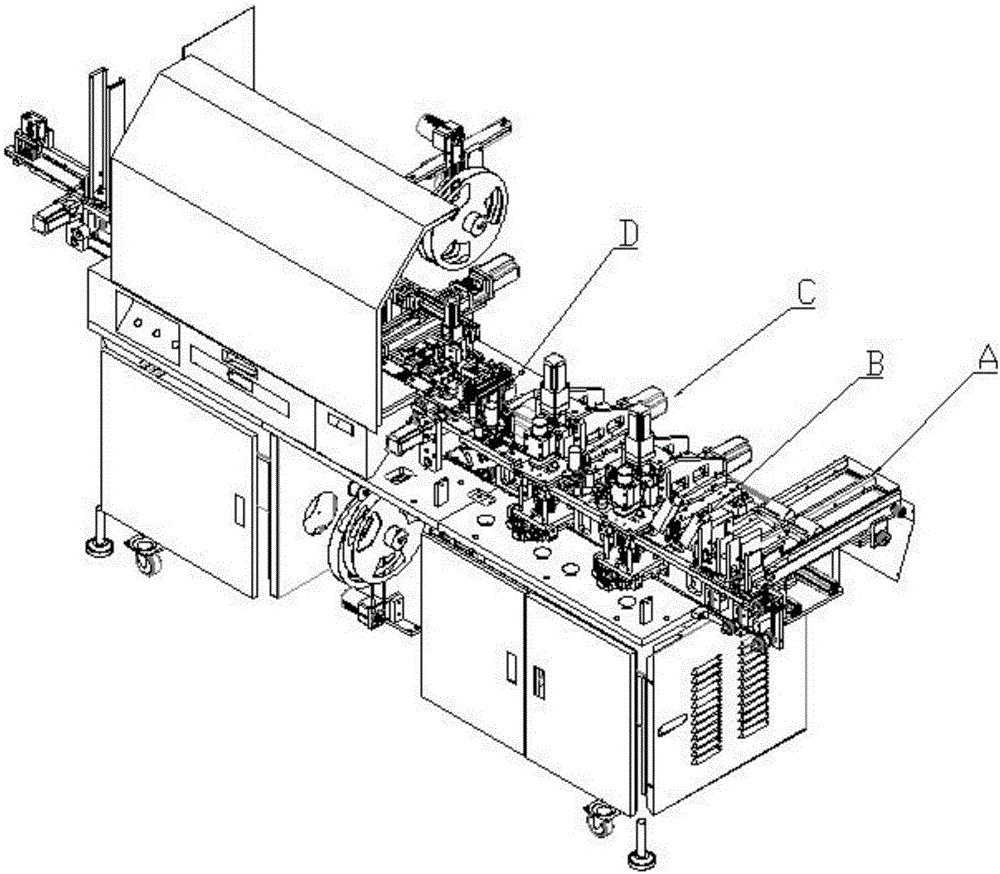

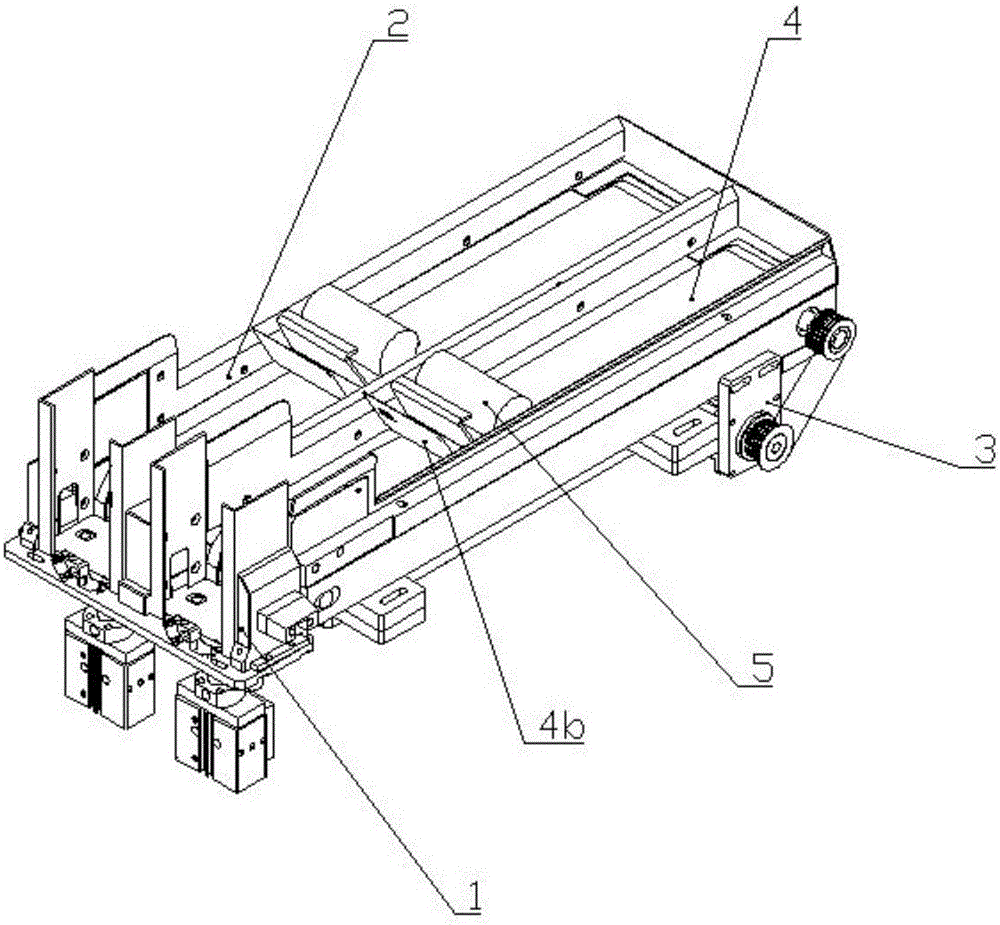

[0057] See Figure 1~Figure 22 , The smart card slot milling equipment of the present invention includes a card issuing unit A, a detection unit B, a slot milling device C and a cleaning device D, wherein:

[0058] The card issuing unit A includes a suction card module 1, which includes a hopper 1-3 and a suction card mechanism located below the hopper 1-3, and the suction card mechanism includes a vacuum suction cup 1-2 and a driving vacuum suction cup 1-2 a vertical drive mechanism for up and down movement, wherein the vacuum suction cup 1-2 is fixedly connected with the vertical movement output member of the vertical drive mechanism;

[0059] The card issuing unit A also includes a smart card replenishment module that includes a smart card storage and positioning slot 2 and a smart card ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com