A smart wrench

An intelligent, sliding block technology, applied in manufacturing tools, motor tools, portable motor devices, etc., can solve the problems of complex structure, practical inconvenience, inconvenience in operation, etc., and achieve the effect of high work efficiency, consistent adjustment, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

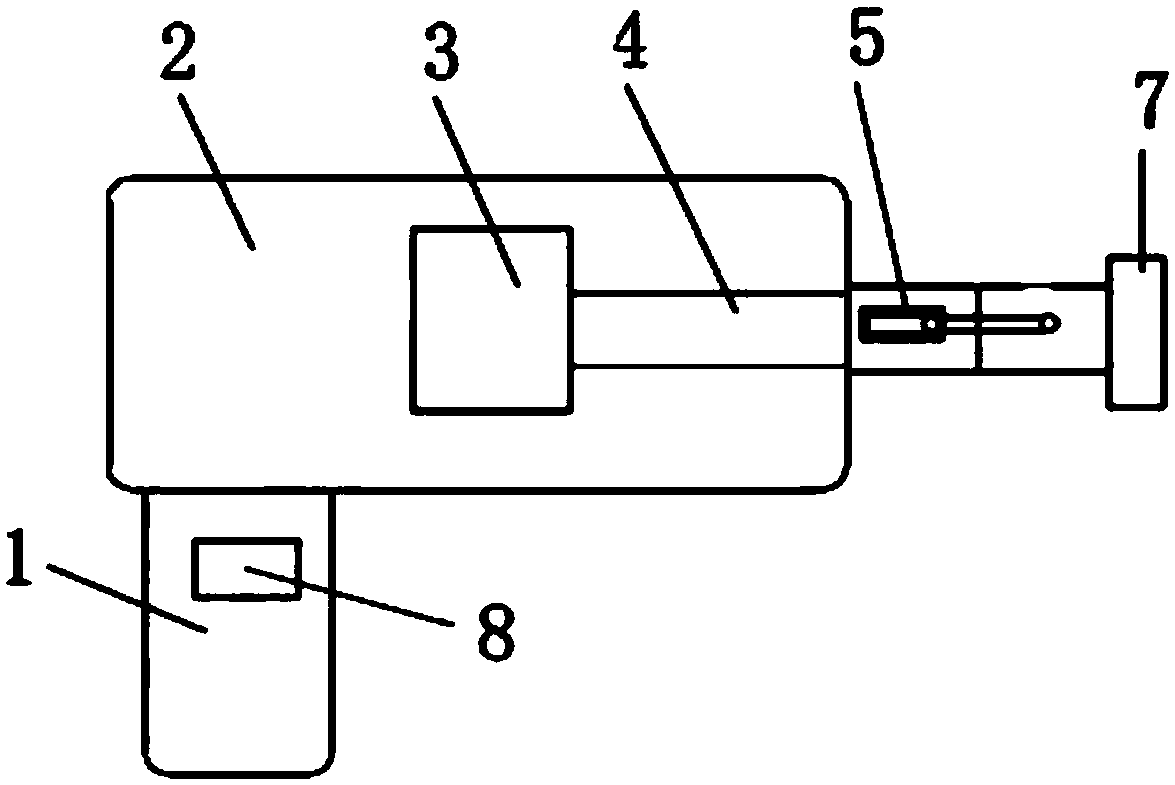

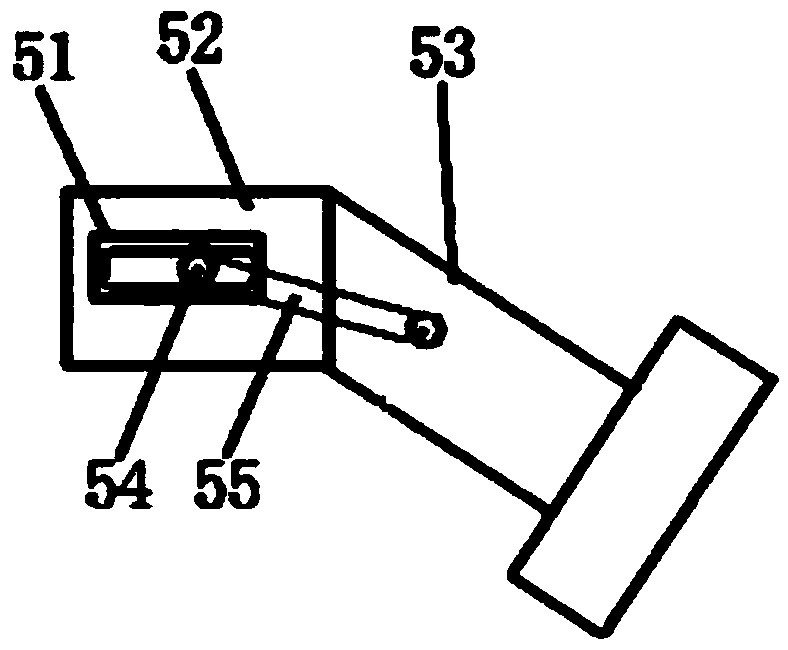

[0032] see Figure 1 to Figure 5 , the smart wrench of this embodiment includes a handle 1, a housing 2, a transmission mechanism and a sleeve 7, the transmission mechanism is arranged in the housing 2 and includes a driving device 3 and a transmission shaft 4 driven by the driving device 3, the transmission The shaft 4 is connected with the sleeve 7. When working, the sleeve 7 matches the bolt and controls the transmission mechanism to start, so as to realize automatic tightening or dismounting.

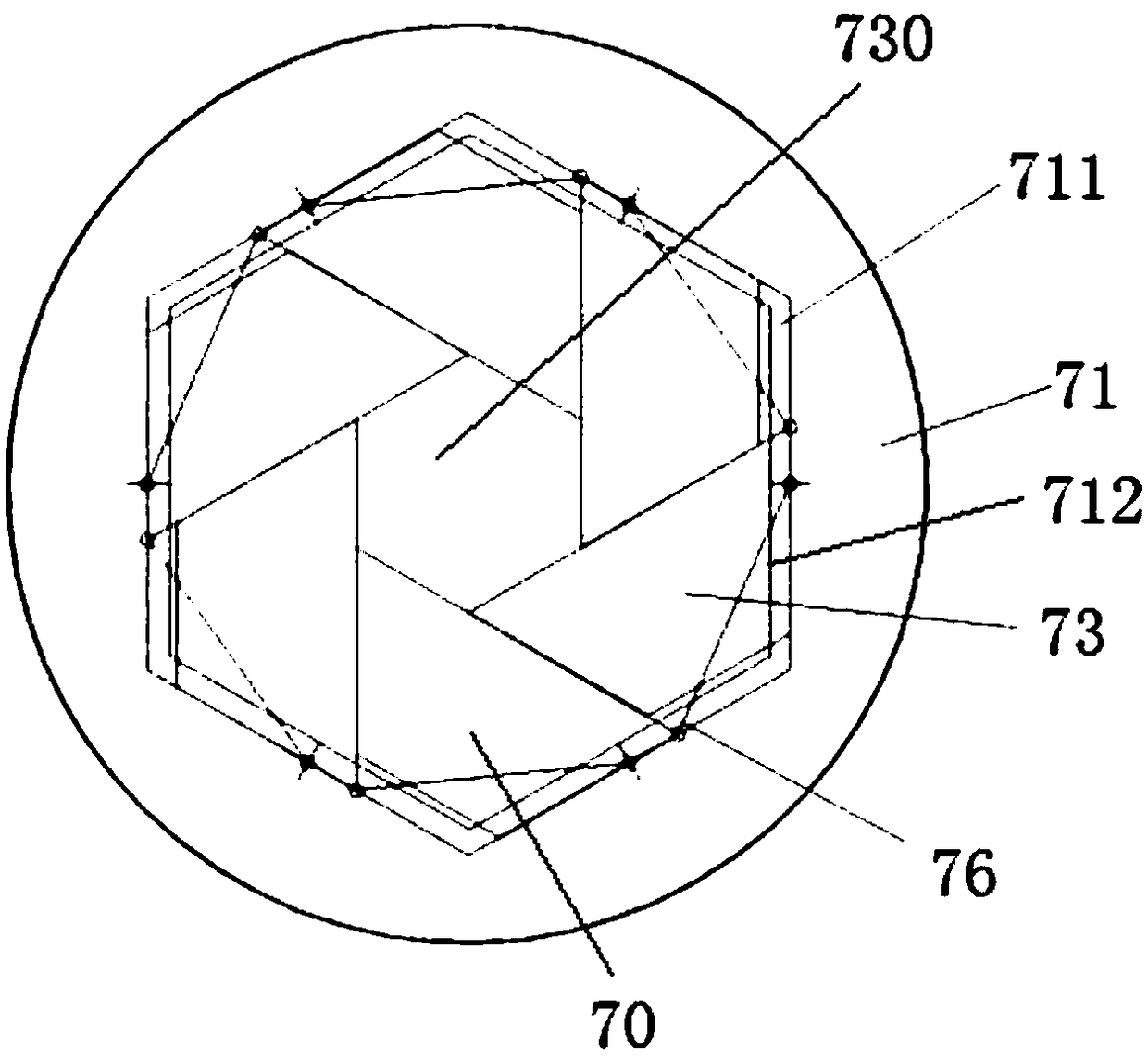

[0033] Such as image 3 and Figure 4 As shown, the sleeve 7 in this embodiment includes a locking disc 71 and an adjustable locking member 70, the adjustable locking member 70 is arranged on the locking disc 71, and the adjustable locking member 70 includes several locking sliders 73 and the number of connecting pieces 74 equal to the locking sliders 73, the two ends of the connecting piece 74 are respectively connected with the adjacent two groups of locking sliders 73, specific...

Embodiment 2

[0045] The usage method of the smart wrench in the present embodiment adopts the smart wrench in the embodiment 1, comprising the following steps:

[0046] 1) Rotate the adjusting ring 75 according to the size of the bolt to be screwed, so that the size of the opening 730 of the adjustable locking member 70 is adapted to it;

[0047] 2) Adjust the universal transmission device 5 through the control device 10, so that the sleeve 7 reaches the required bending angle;

[0048] 3) set required torque by control device 10;

[0049] 4) Start the device through the control device 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com