Physical quantity inspection device

An inspection device and technology for physical quantities, applied in the field of physical quantity inspection, can solve problems such as inconvenience, large size, and inaccuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

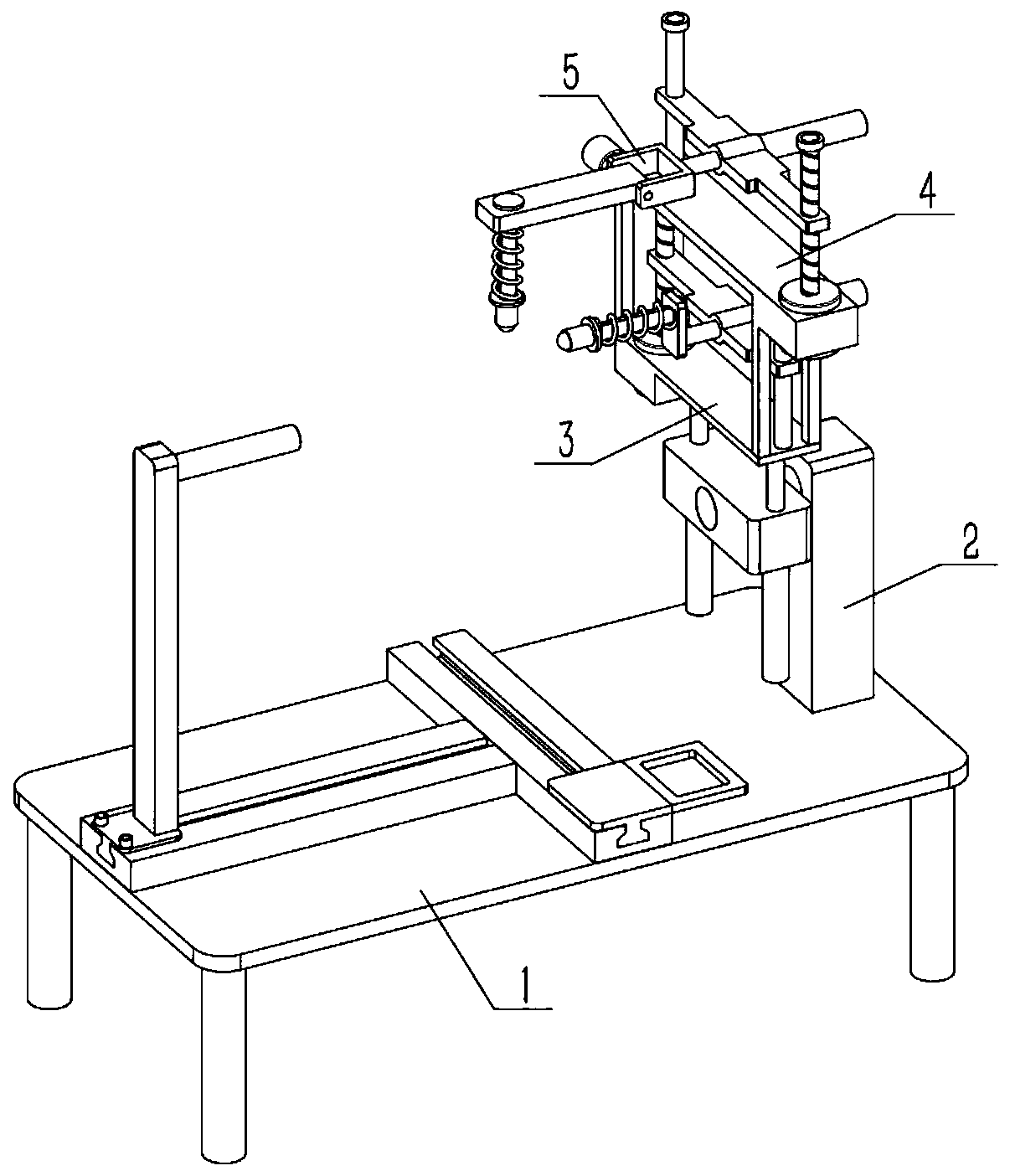

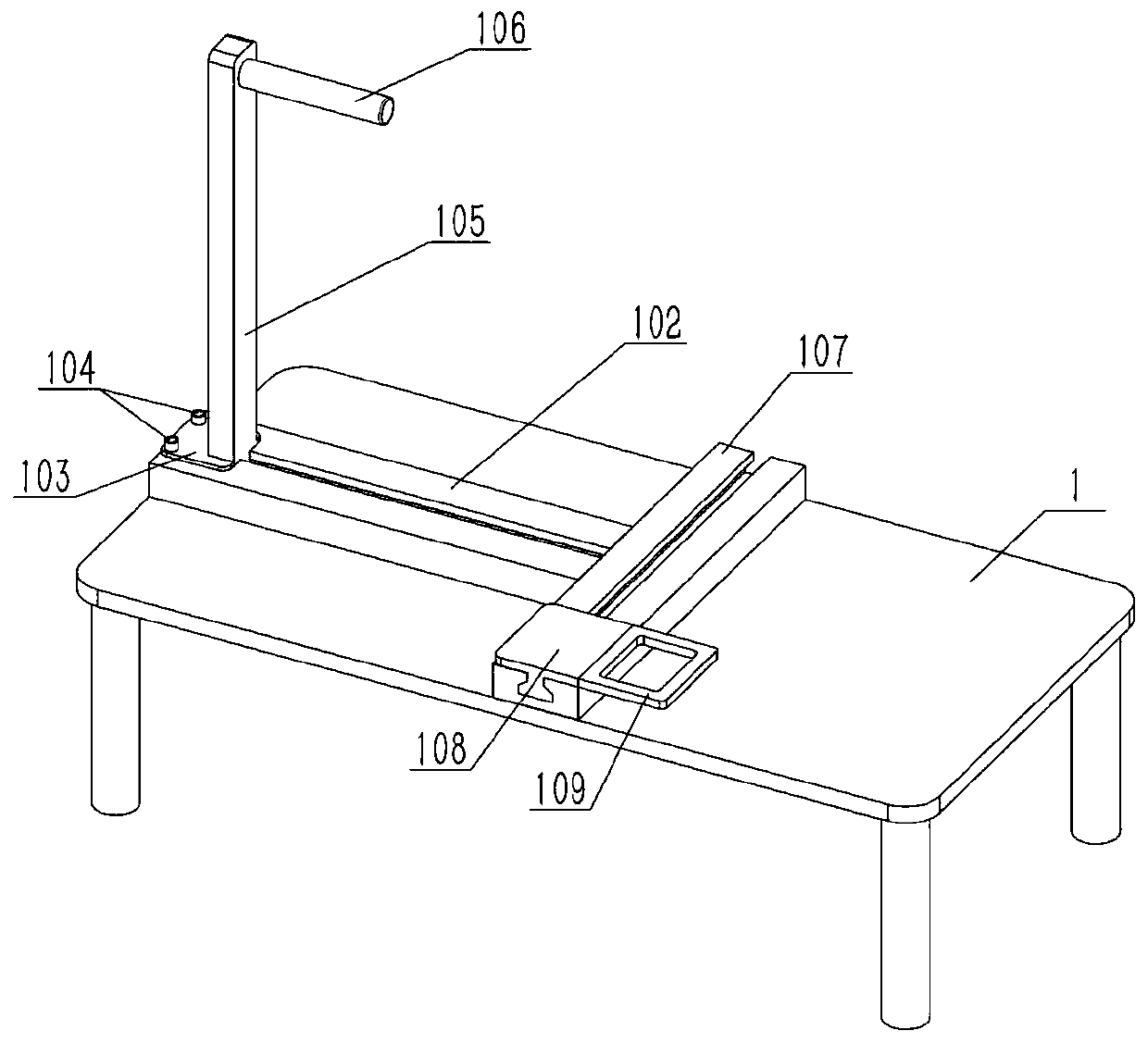

[0028] Such as Figure 1-7 As shown, a physical quantity inspection device includes a base block I306, a slide rod I307, a limit piece I308, a stop piece I309, a compression spring I310, a universal joint I311 and a universal ball I312. The left and right ends of the rod I307 and the slide rod I307 are fixedly connected to the contact piece I309 and the limit piece I308 respectively. Between the pieces I309, the universal joint I311 is fixedly connected to the left end of the counter piece I309, and the universal ball I312 is installed in the universal joint I311. The end surface to be detected is contacted with the universal ball I 312 and the universal ball I 312 is contracted to a certain extent. The contraction is that the compression spring I 310 continues to shrink due to the compression of the universal ball I 312 by the end surface to be detected. If the end face to be detected is horizontal, pass the end face to be detected over the universal ball I312 in a straight ...

specific Embodiment approach 2

[0030] Such as Figure 1-7 As shown, the physical quantity inspection device also includes a matching plate 503, a sliding rod II 504, a limit piece II 505, a stop piece II 506, a compression spring II 507, a universal joint II 508 and a universal ball II 509. The left side of the adjusting plate 503 is slidingly connected to The sliding rod II504, the upper and lower ends of the sliding rod II504 are fixedly connected with the limit piece II505 and the abutment piece II506 respectively, the limit piece II505 is located above the allocation plate 503, and the compression spring II507 is set on the slide bar II504 and is located between the allocation plate 503 and the abutment plate 503. Between the pieces II506, the universal joint II508 is fixedly connected to the lower end of the supporting piece II506, and the universal ball II509 is installed in the universal joint II508; the universal ball II509 is located above the left side of the universal ball I312, and the axis of th...

specific Embodiment approach 3

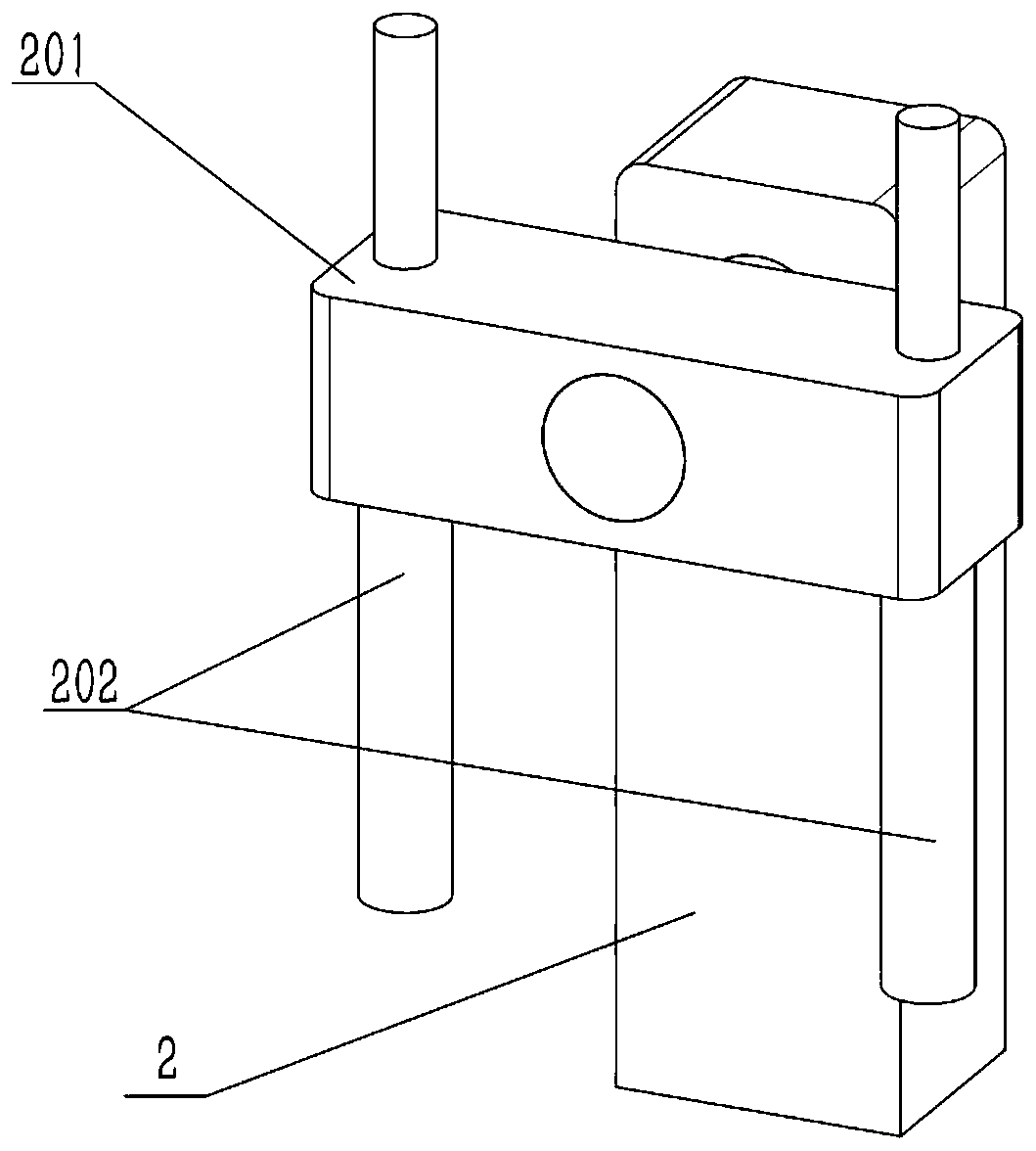

[0032] Such as Figure 1-7As shown, the physical quantity inspection device also includes a base II3, a motor II301, a lead screw I302, a round rod I303, and an adjustment table I304. The shaft is fixed, the round rod I303 is fixed on the rear side of the base II3, the front side of the adjustment table I304 is threaded with the screw I302, the rear side of the adjustment table I304 is slidingly connected with the round rod I303, and the base block I306 is installed on the adjustment table On the left side of I304. Start the motor Ⅱ301, the output shaft of the motor Ⅱ301 drives the screw Ⅰ302 to rotate, the screw Ⅰ302 drives the adjustment table Ⅰ304 to rise and fall, the adjustment table Ⅰ304 can adjust the height of the universal ball Ⅰ312, and then the object to be measured can be kept still. The position of the universal ball I312 can be changed to check different positions of the end faces to be tested, and the distance between the universal ball I312 and the universal b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com