A vertical compression static load test device for engineering piles

A compressive static load and test device technology, which is applied in basic structure engineering, basic structure testing, construction, etc., can solve problems such as safety and load performance reduction, and achieve improved safety, small overturning force, and overall lower center of gravity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is further described in conjunction with the following examples.

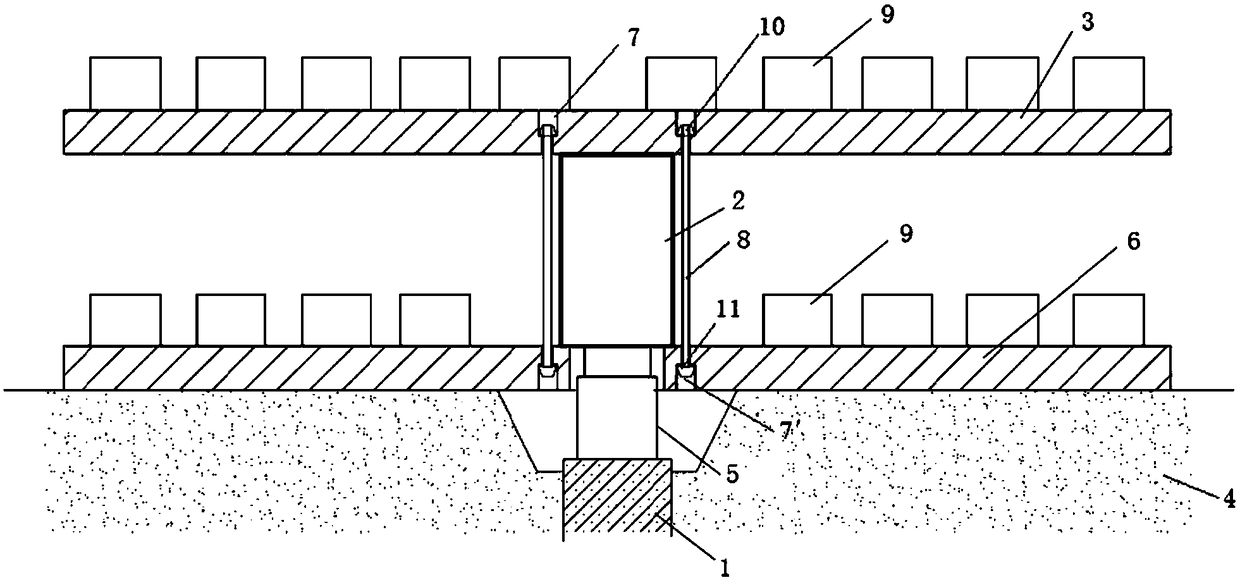

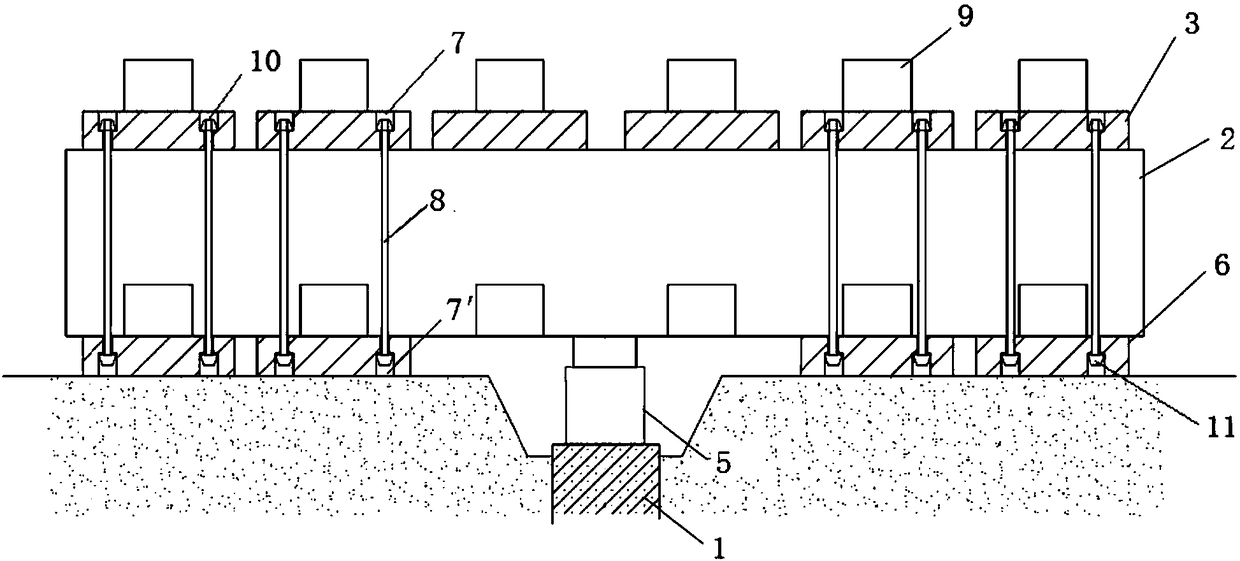

[0020] see Figure 1 to Figure 4 , a vertical compression static load test device for engineering piles of the present embodiment, comprising main beams 2, secondary beams 3, base pad beams 6, jacks 5 and pull rods 8, the test pile 1 is embedded in the ground 4 and is perpendicular to It is set on a horizontal plane, and a jack 5 is placed on its top surface, the main beam 2 is arranged directly above the jack 5, and the secondary beam 3 is placed on the top of the main beam 2 vertically in the direction of the main beam 2, and the two sides of the test pile 1 are respectively set Two base pad beams 6 placed on the ground 4, the base pad beams 6 are all perpendicular to the placement direction of the main beam 2, and the secondary beam 3 and the base pad beam 6 are correspondingly provided with a first slot for installing the tie rod 8 7. The second card slot 7', by installing the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com