Tray

A technology of pallets and beams, applied in the direction of lifting devices, etc., can solve problems such as increased operational difficulty, interlude cargo, and pallet function constraints, and achieve the effects of reducing loading and unloading labor costs, reducing packaging damage, and reducing shipping costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

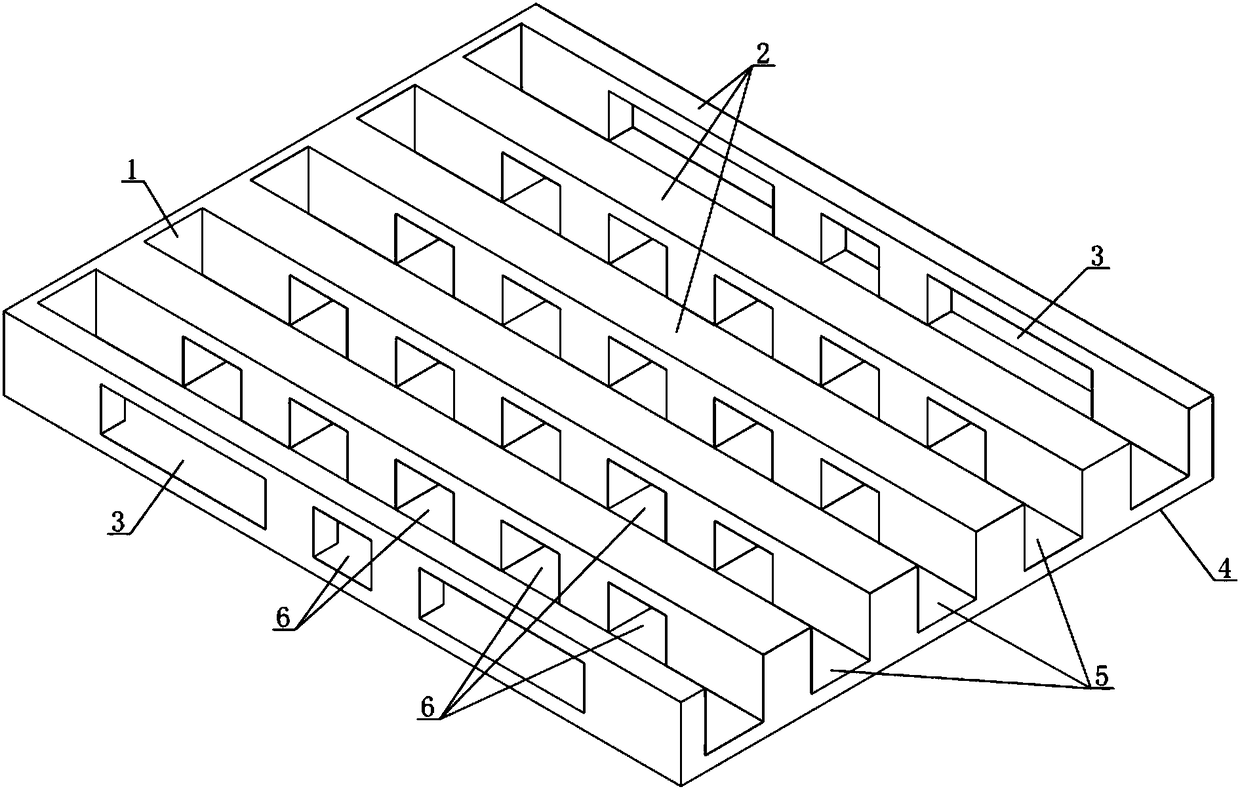

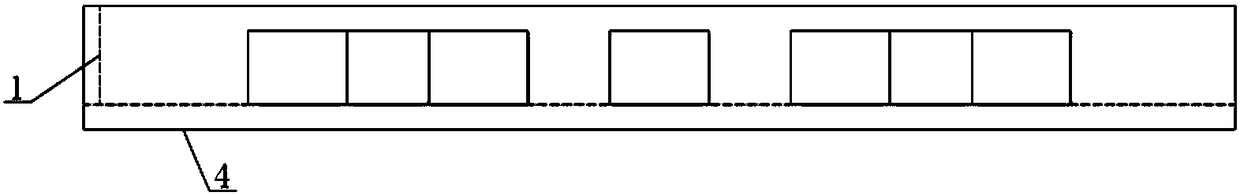

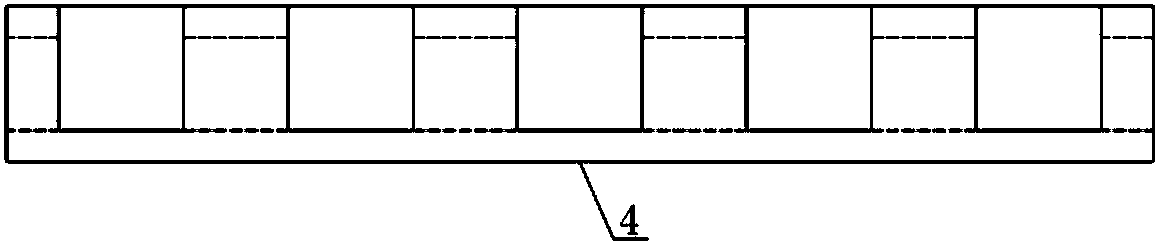

[0020] The pallet of the present invention is a tool for the operation of handling and unloading equipment, and has a bottom plate 4, which is a flat plate, so that the pallet can be passed through the automatic packaging line, and can also isolate the upper and lower layers of goods, so that the overall stability of the pallet is good; the bottom plate There are 6 parallel beams 2 (corresponding to the number of forks of the forklift) on the top, and the groove-shaped passage 5 formed between the beams is convenient for the insertion of the forks of the forklift; each beam is provided with a through hole 6 in the vertical direction. The adjacent through holes are opposite to each other. Among them, there are 3 through holes on the beam on the side of the bottom plate, and the through holes at both ends are large through holes 3. The large through holes correspond to the positions of the pallet forks on the automatic packaging machine. Other beams are equipped with 5 through ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com