A deicer for power wires and cables

A deicer and cable technology, applied in the installation of cables, electrical components, overhead installation, etc., can solve the problems of increased burden on utility poles, electric shock, disasters of pedestrians and residents’ houses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

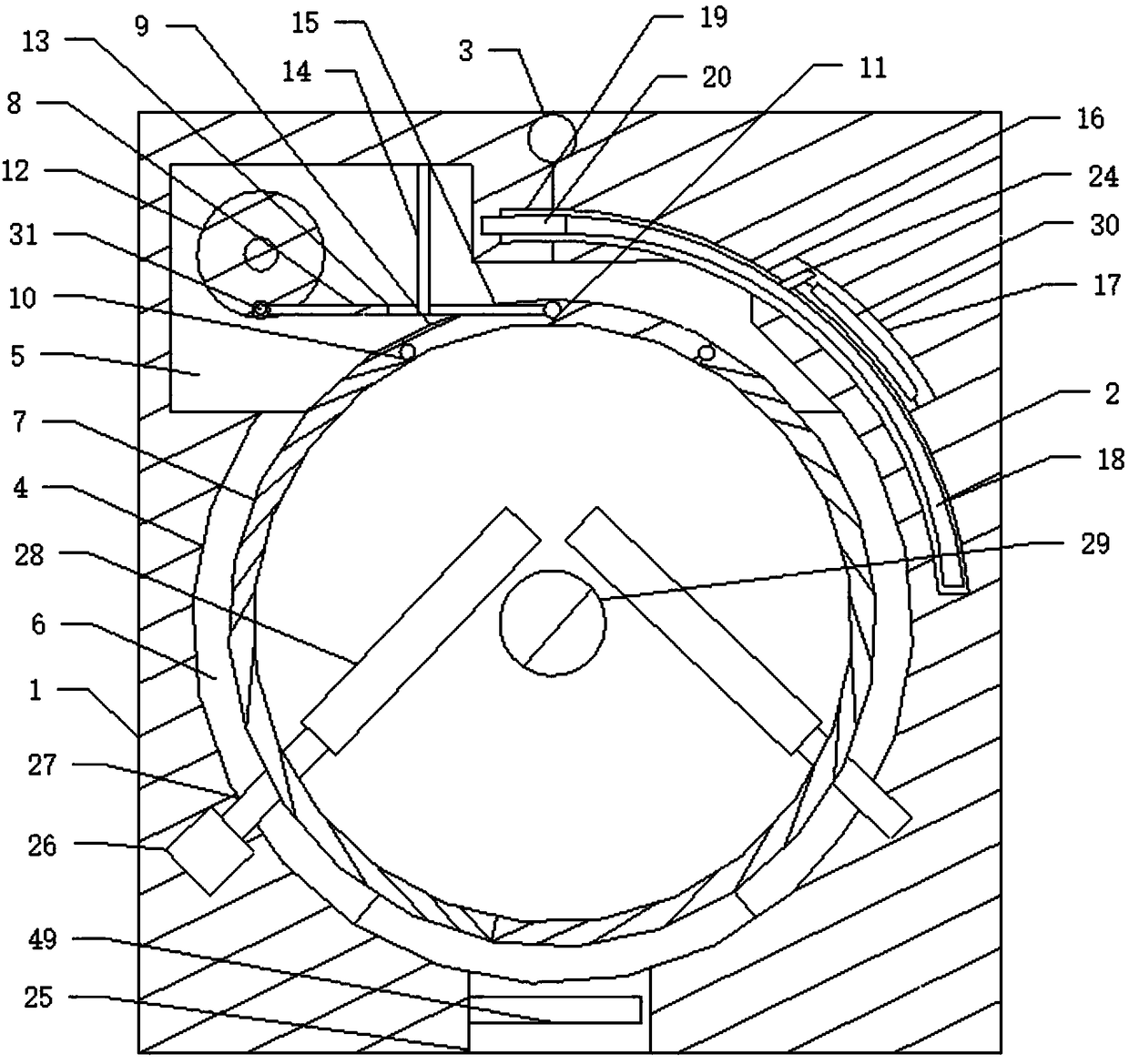

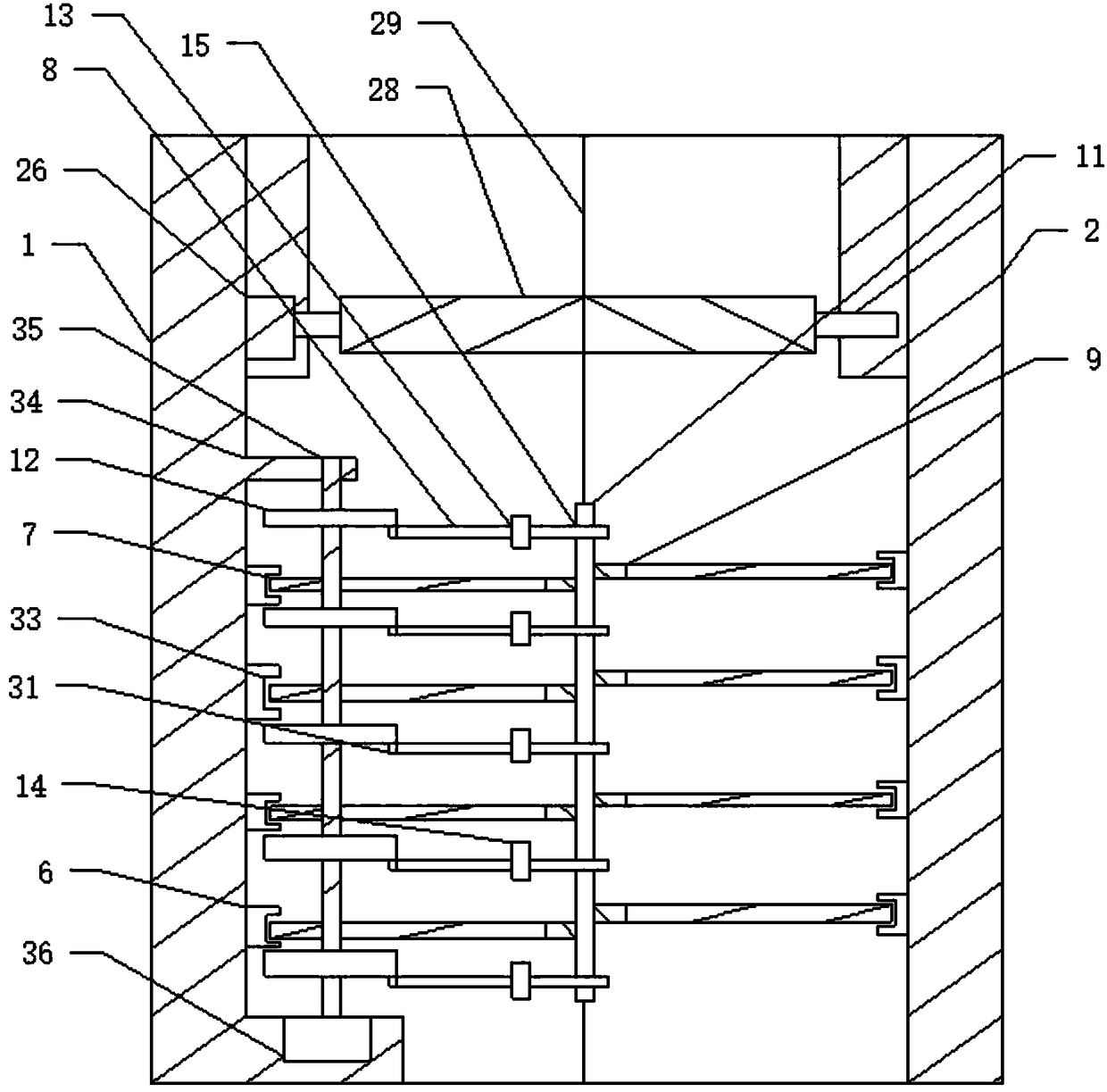

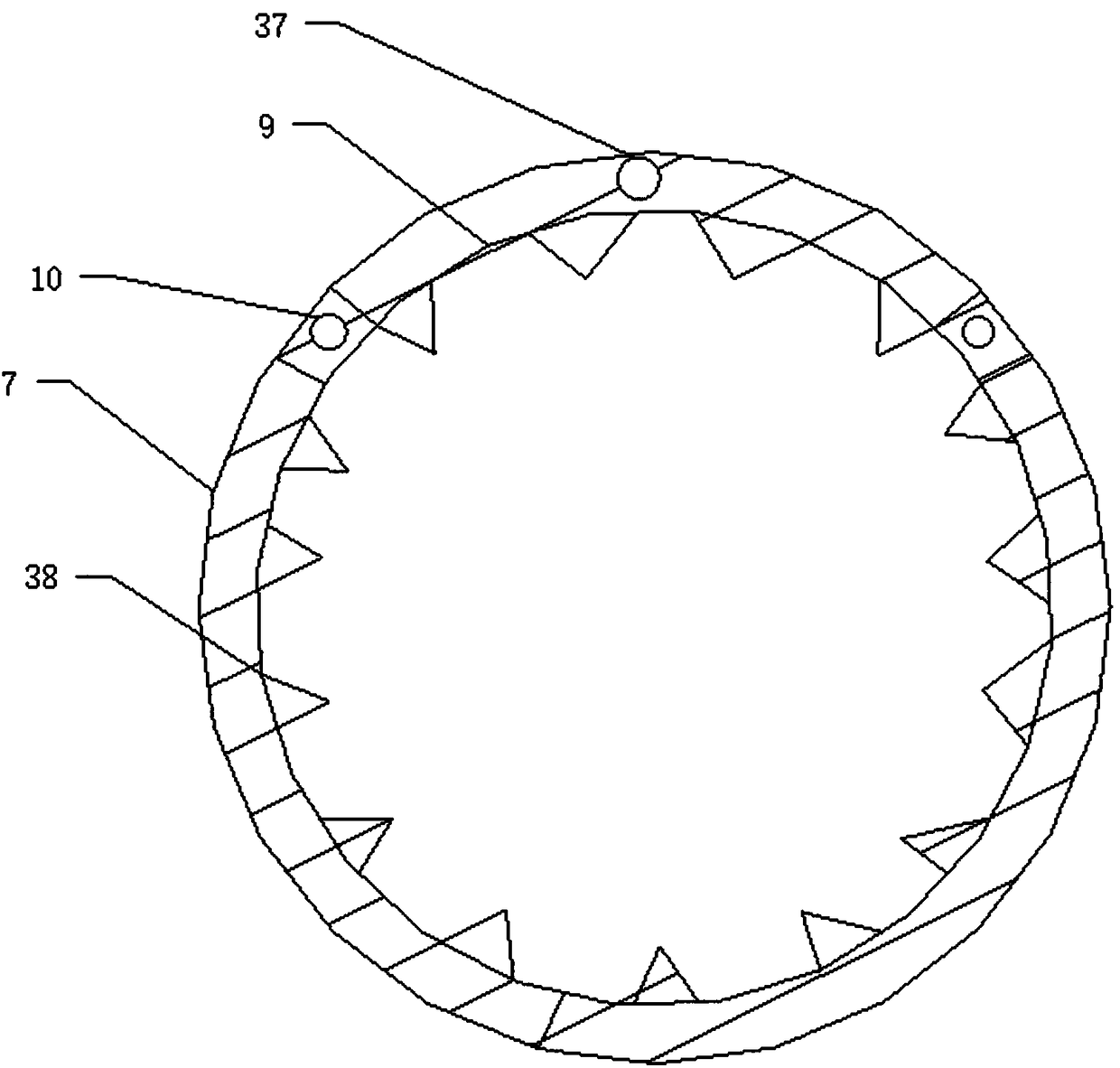

[0028] Such as Figure 1 to Figure 8 As shown, a power wire and cable deicer includes a cable 29 on which a first body 1 and a second body 2 are arranged, and the first body 1 and the second body 2 Correspondingly connected by a first connecting shaft 3, the first body 1 and the second body 2 are respectively provided with a semicircular deicing groove 4, and the deicing groove 4 is connected to the cable 29. Correspondingly, the first body 1 is provided with a power chamber 5 corresponding to the deicing tank 4, and the power chamber 5 is provided with a second rotating shaft 35 driven by a second motor 36, and the second rotating shaft 35 is provided with a row of driving runners 12, each of which includes a first drive shaft 8 that rotates on the driving runners 12, and is also provided with a row of The deicing groove 4 corresponds to the connecting ice blade 9, and the two ends of the connecting ice blade 9 are respectively connected to a corresponding deicing blade disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com