Optimal method of deicing mode based on combined shear stress of piezoelectric sheet excitation and lamb wave

A piezoelectric sheet and shear stress technology, which is applied in the field of combined shear stress deicing based on piezoelectric sheet excitation and Lamb wave, can solve the problems of aircraft crashes, aircraft lift performance reduction, wing and fuselage vibration and noise and other issues, to achieve the effect of broad application prospects, high reliability, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make those skilled in the art better understand the solutions of the present application, the following will clearly and completely describe the technical solutions in the embodiments of the present application with reference to the accompanying drawings in the embodiments of the present application.

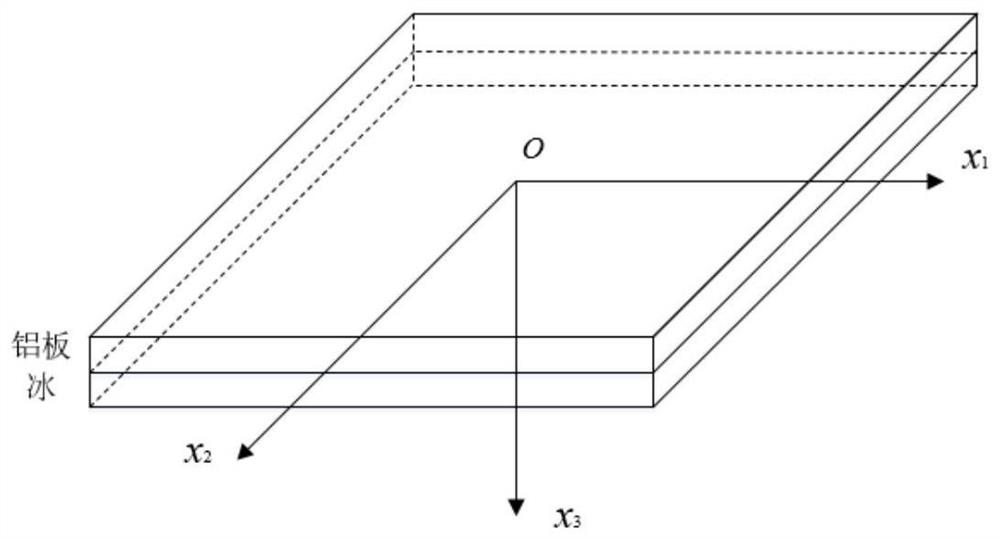

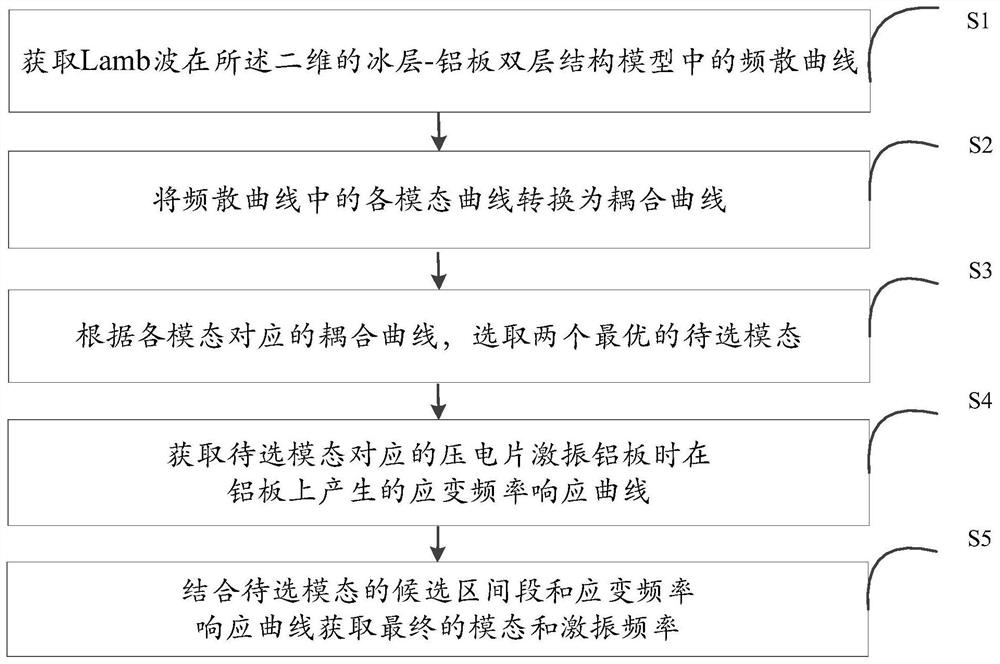

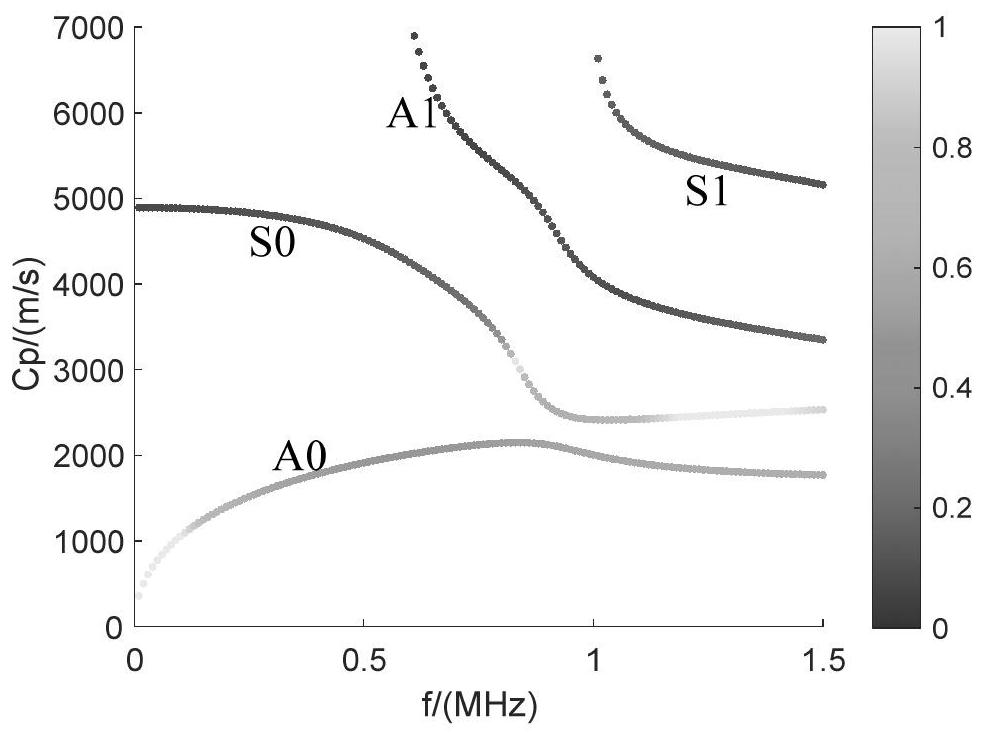

[0029] Since the adhesion normal stress between the wing and the ice accretion is greater than the adhesion shear stress, it is of great benefit to aircraft deicing from the point of view of the adhesion shear stress. Lamb waves can excite normal stress and shear stress on the wing, that is, out-of-plane displacement and in-plane displacement can be generated on the surface of the wing, and the in-plane displacement plays a major role in the deicing process. The application of wing anti-icing has obvious advantages. At the same time, the ultrasonic guided wave anti-icing technology also has the advantages of low power consumption, low cost, light weight, simpl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com