Drafting mechanism with multiple fiber belt guide devices

A fiber belt and guide technology, applied in drafting equipment, fabric elongation, spinning machine, etc., can solve problems affecting fiber belt quality, fiber belt width drafting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

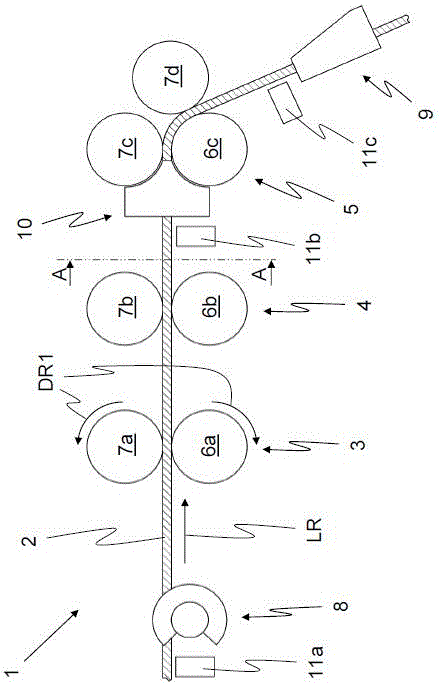

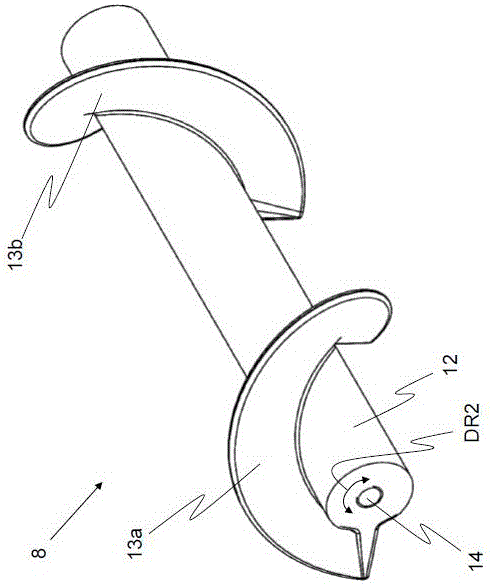

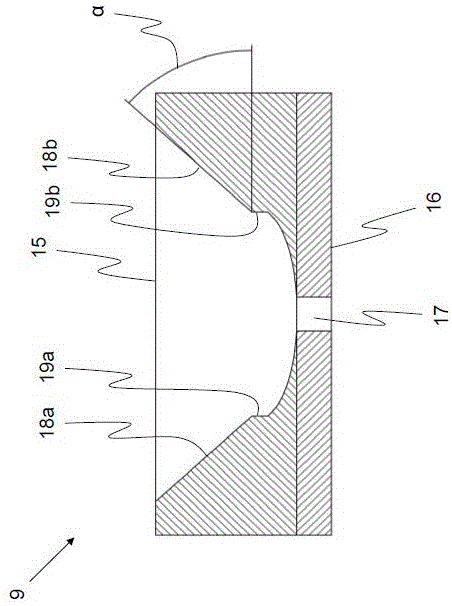

[0034] figure 1 The drafting unit 1 with three roller pairs 3 , 4 , 5 and three fiber web guides 8 , 9 , 10 is shown in side view. The three roll pairs 3 , 4 , 5 here comprise an input roll pair 3 , an intermediate roll pair 4 and an output roll pair 5 . The respective roll pair 3, 4, 5 also comprises at least one lower roll 6a-6c and at least one upper roll 7a-7d, respectively. The roll pairs 3 , 4 , 5 have a direction of rotation DR1 , which is shown by way of example on the input roll pair 3 . The direction of rotation of the lower roll 6 a and the upper roll 7 a is oriented oppositely, so that the fiber strip 2 , which is guided between the pair of feed rolls 3 , is entrained. The fiber strip 2 is conveyed in its direction of travel LR by the drafting unit 1 , so that it is guided through the intermediate pair of rollers 4 after entering the pair of rollers 3 . The lower roll 6 b and the upper roll 7 b of the intermediate roll pair 4 here have the same direction of rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com