Optical zoom cam curve detection device and detection method

A detection device and cam curve technology, applied in the direction of using optical devices, measuring devices, instruments, etc., to ensure uniqueness, improve detection efficiency and reliability, and ensure operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

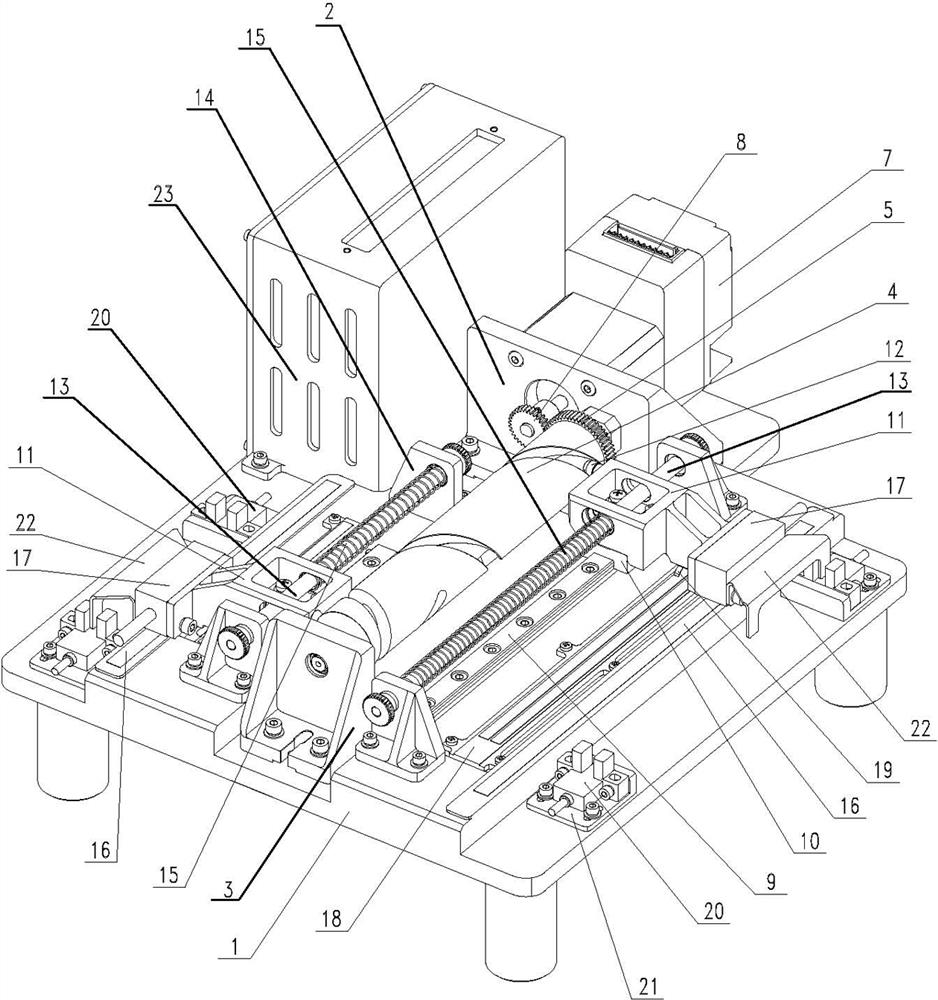

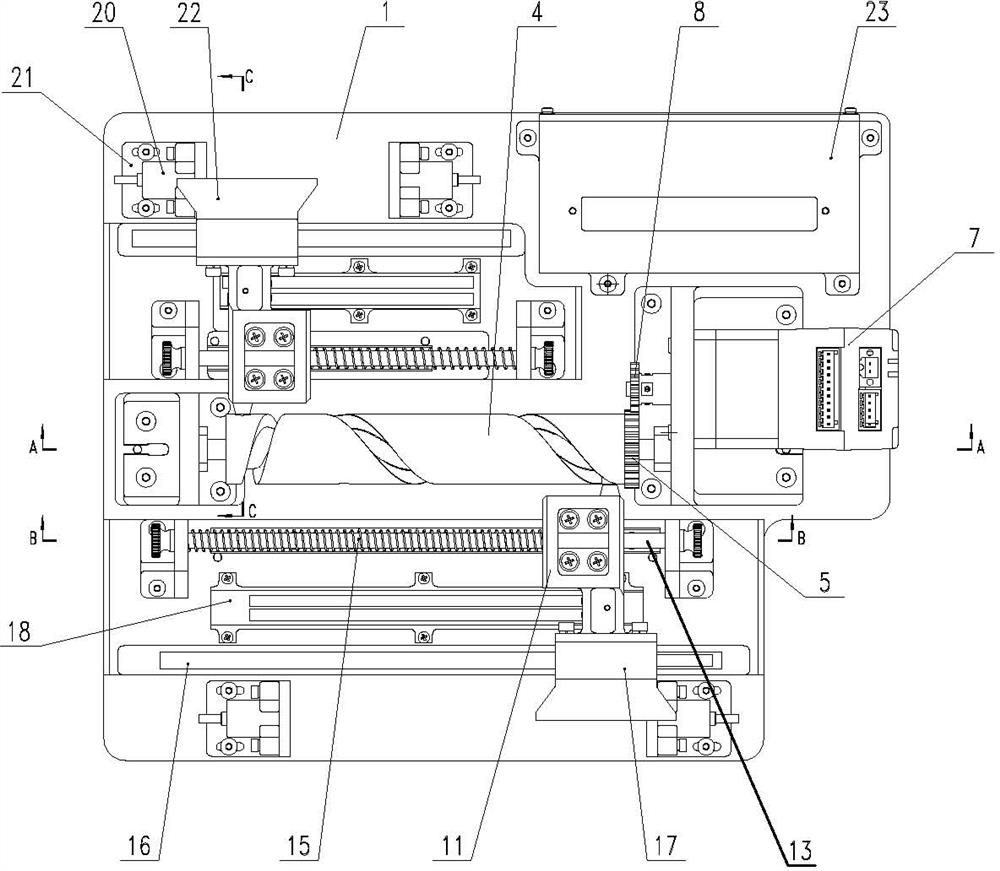

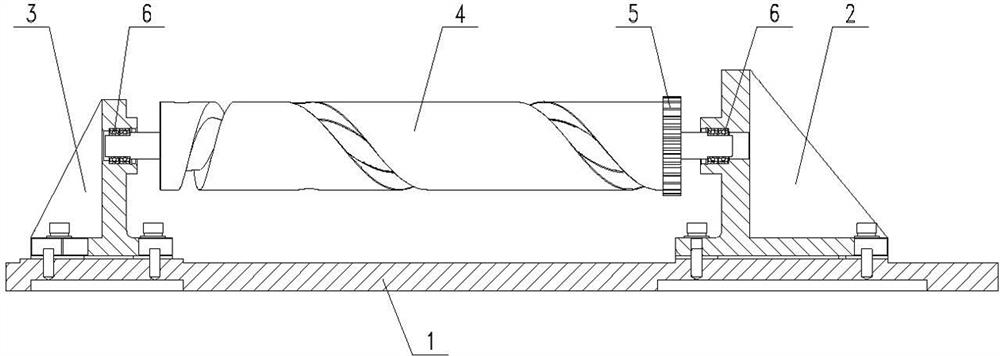

[0039] Embodiment 1: An optical zoom cam curve detection device, the monitoring device includes a working platform 1, a camshaft transmission mechanism, a linear motion sliding group, an anti-backlash spring assembly, a grating ruler 16 detection assembly, a potentiometer 18 detection assembly, a limit The switch 20 assembly and the electric control box 23, the camshaft transmission mechanism is fixed in the middle of the work platform 1, and two sets of linear motion sliding groups are installed on both sides of the camshaft transmission mechanism, parallel to the cam transmission mechanism, and connected with the cam transmission mechanism; two sets The anti-backlash spring assembly is arranged on both sides of the camshaft transmission mechanism, parallel to the camshaft transmission mechanism, and respectively connected with the linear motion sliding group; two sets of grating ruler 16 detection components are respectively installed outside the two sets of linear motion slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com