Heteropolar Permanent Magnet Bias Hybrid Radial Magnetic Bearings

A permanent magnet bias and hybrid radial technology, applied in the field of magnetic bearings, can solve the problems of large electric excitation loss, magnetomotive force, leakage of permanent magnets, and large radial size, so as to improve space utilization and dynamic loss. Low, the effect of reducing the outer diameter of the stator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

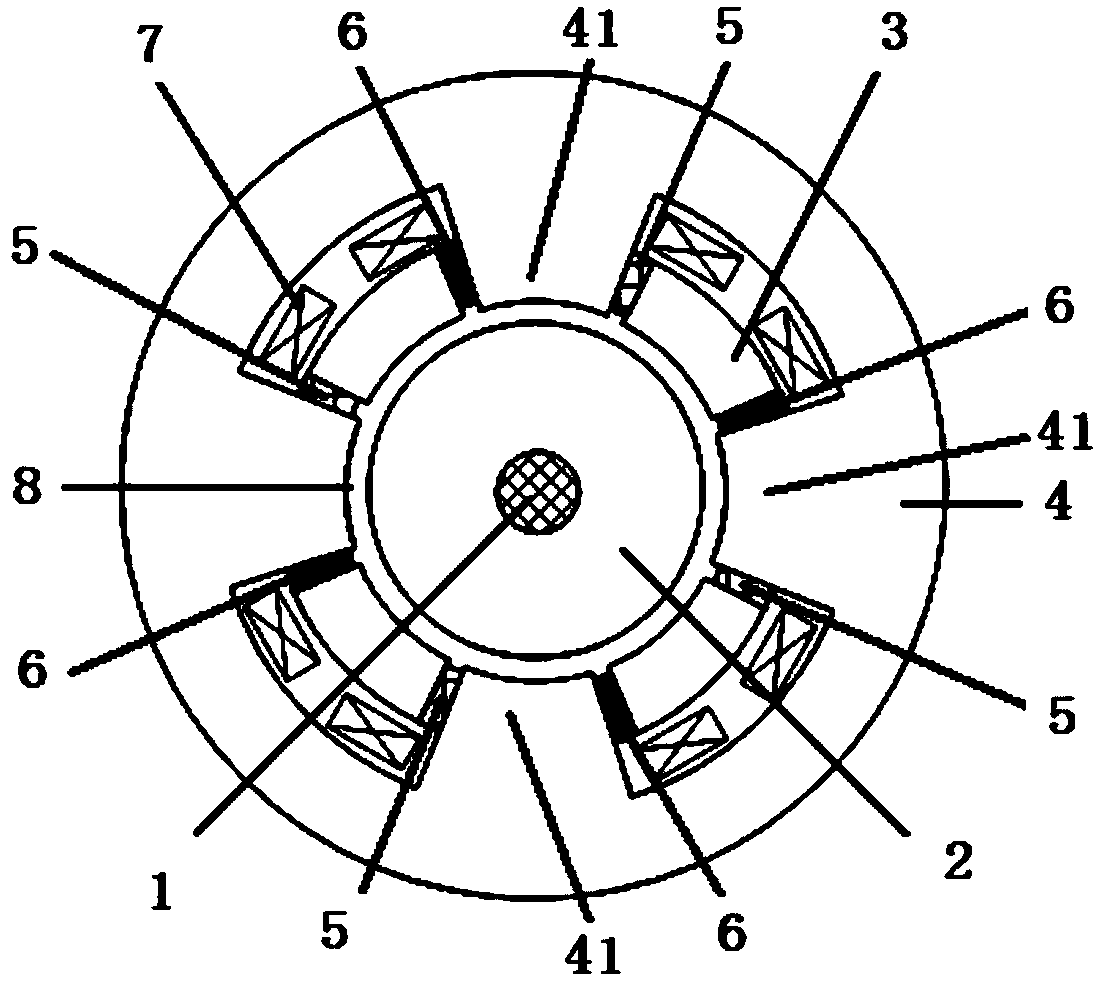

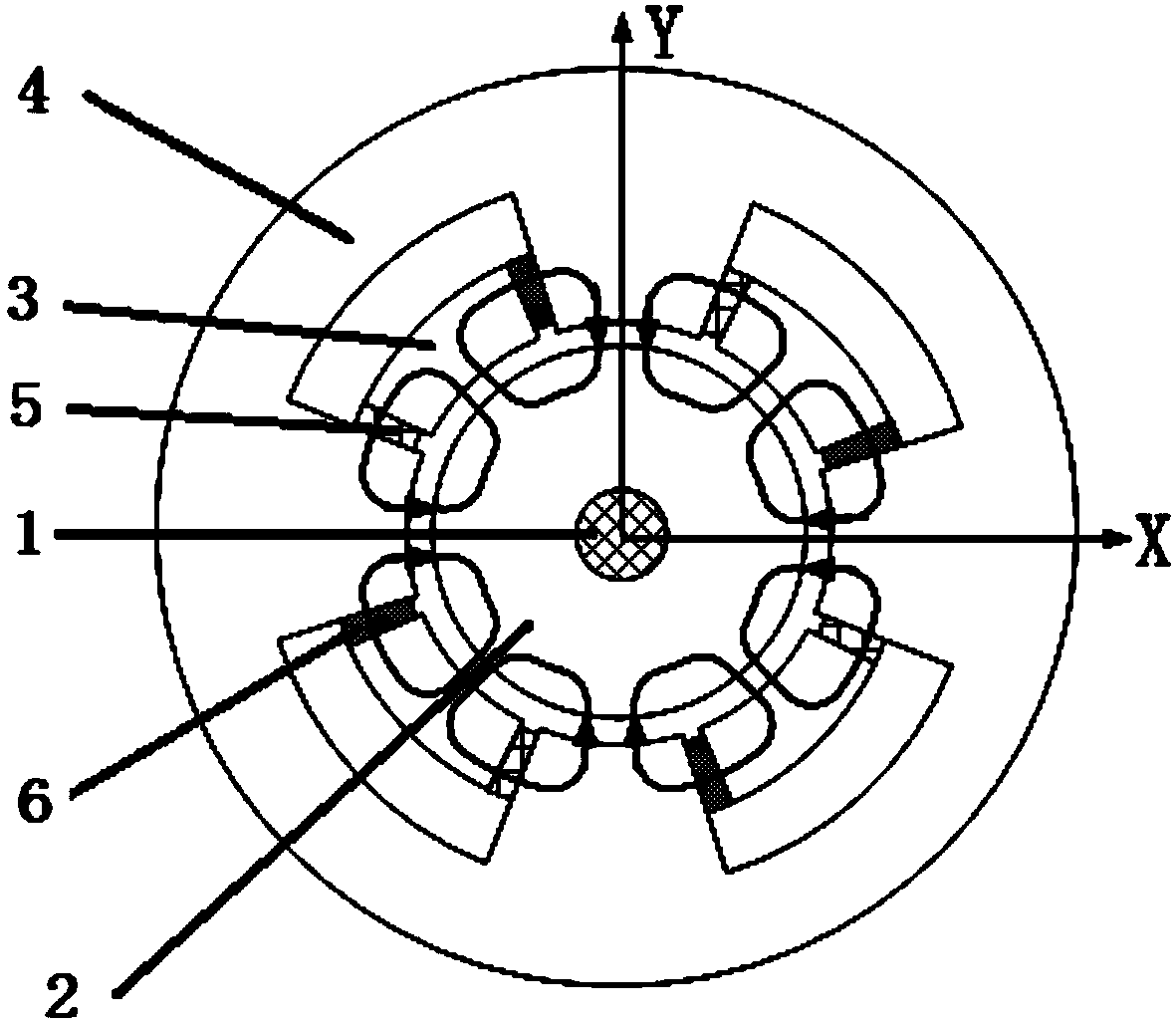

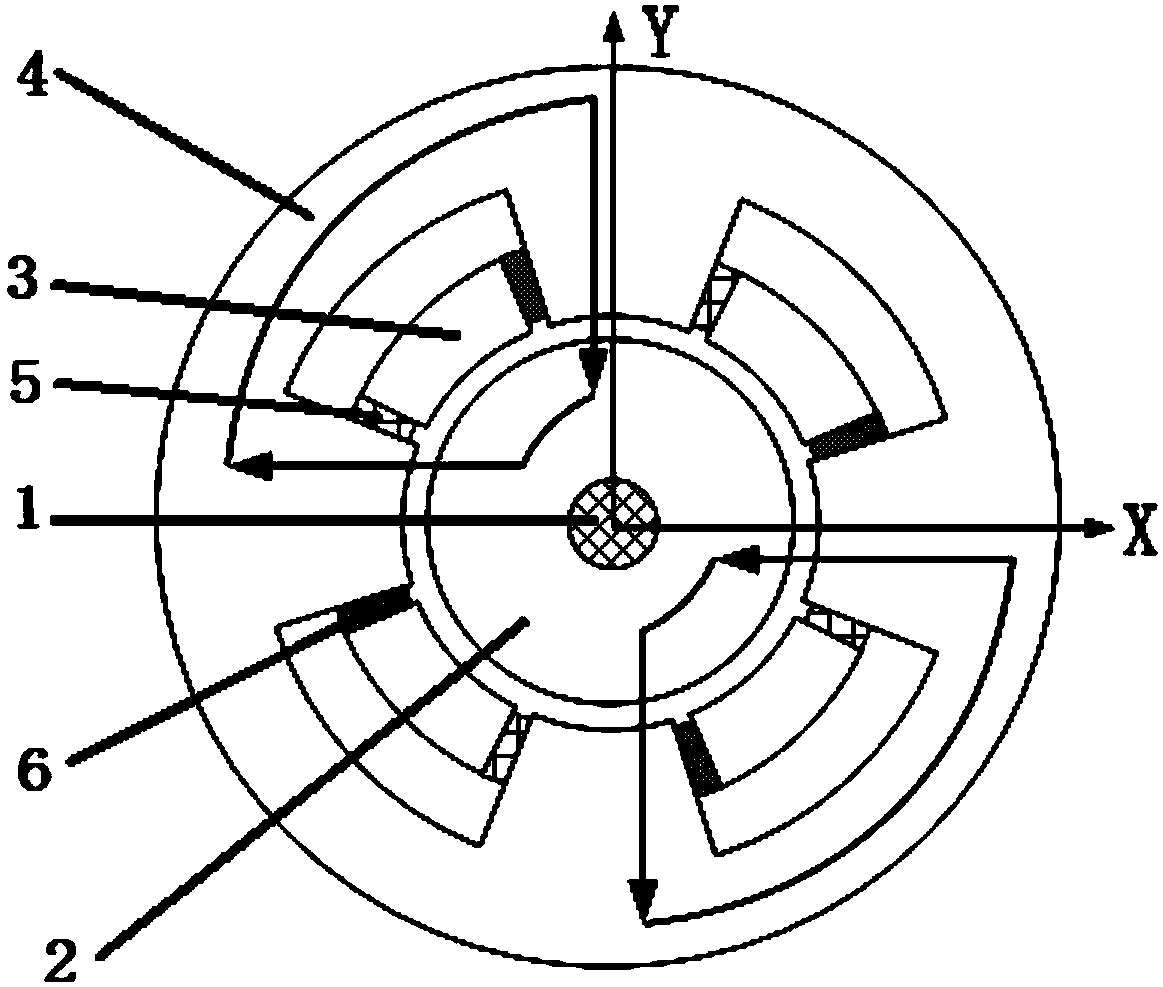

[0029] see figure 1 , The heteropolar permanent magnet bias hybrid radial magnetic bearing provided by the preferred embodiment of the present invention includes a stator assembly and a rotor assembly magnetically suspended in the stator assembly.

[0030] The rotor assembly includes a rotating shaft 1 and a rotor core 2 arranged outside the rotating shaft 1 . The rotor core 2 is shrink-fitted on the rotating shaft 1, and the size of the rotating shaft 1 depends on the design of the entire rotor system. The inner and outer surfaces of each component of the rotor assembly (rotating shaft 1, rotor core 2) are smooth curved surfaces. From the perspective of reducing size and improving space utilization, the rotating shaft 1 is preferably made of high-strength alloy steel. In this embodiment, the rotating shaft 1 is made of 25Cr2Ni4MoV,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com