Clamping jaw

A technology of clamping jaws and chucks, applied in the directions of chucks, manipulators, manufacturing tools, etc., can solve the problems of low machining accuracy of milling machines, low structural precision of clamping jaws, and defective products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

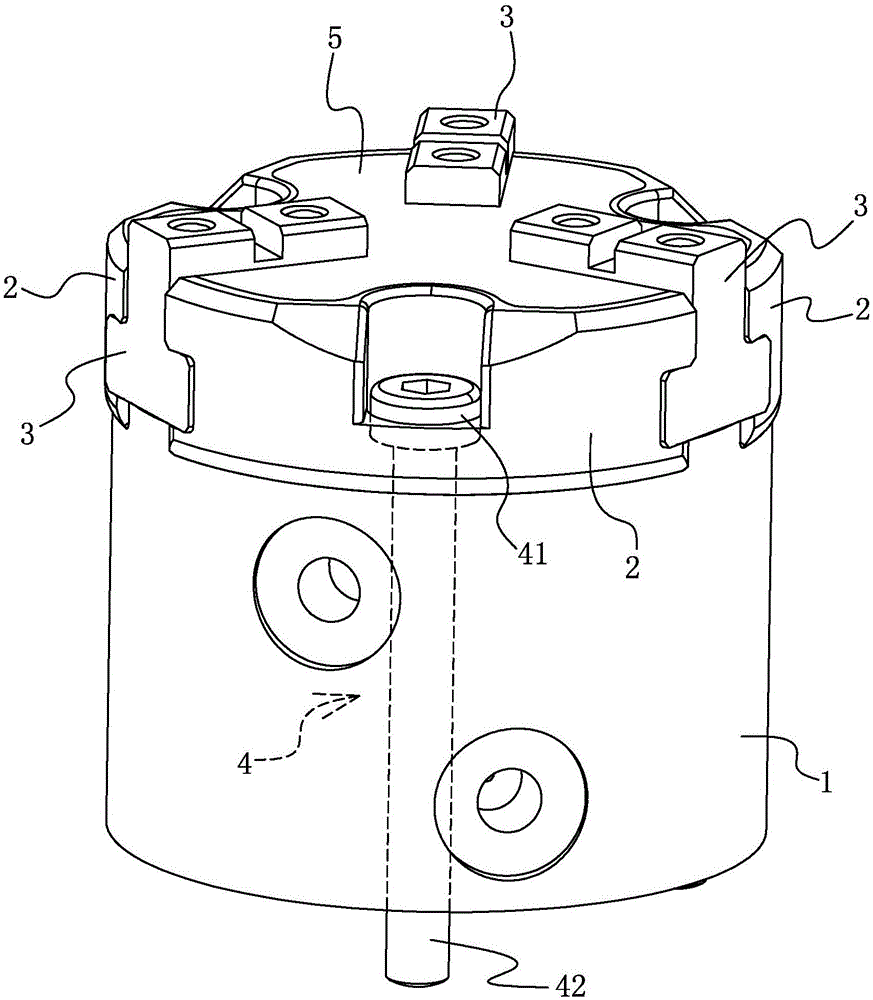

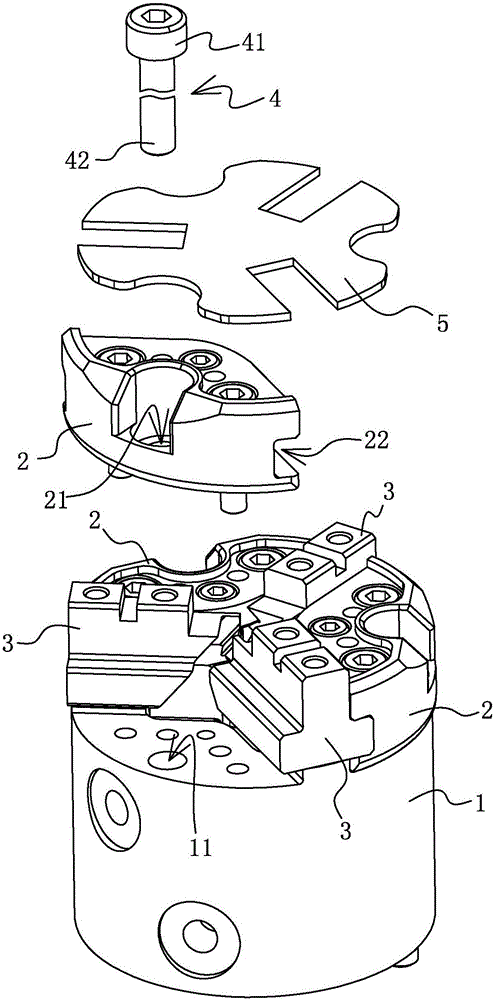

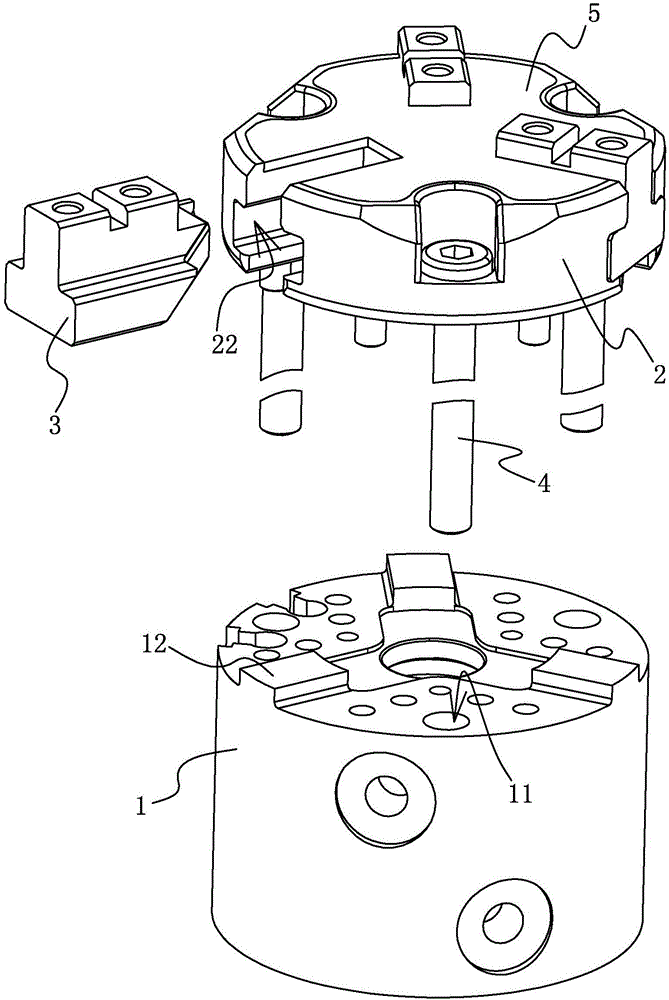

[0016] Such as figure 1 and figure 2 As shown, the jaw in this embodiment includes a body 1 and a base 2 fixedly connected to the body 1 . The number of the base 2 is three, and the base 2 has three clamping heads 3 which are movable. Between two adjacent bases 2, there is a groove 22 for the sliding of the chuck 3. There is a distance between the groove and the bottom surface of the base, and the grooves on the two adjacent bases form a chute for the sliding of the chuck. , The chuck 3 is located in the groove 22 . Three bases 2 and three clamping heads 3 are arranged at intervals and distributed in a circle. The top of the base 2 is provided with a cover plate 5 for dustproofing.

[0017] Of course, as other alternatives, the number of bases 2 and chucks 3 can be two or more.

[0018] Such as image 3 As shown, the upper side of the body has the same number of protrusions as the base, the upper side of the protrusion is adjacent to the lower side of the chuck, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com