A cinnabar handicraft processing device with stepwise distribution of multi-drill bits

A processing device and multi-drill technology, applied in the direction of stone processing tools, stone processing equipment, work accessories, etc., can solve the problems of insecurity and low efficiency, and achieve the effect of efficient and safe processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

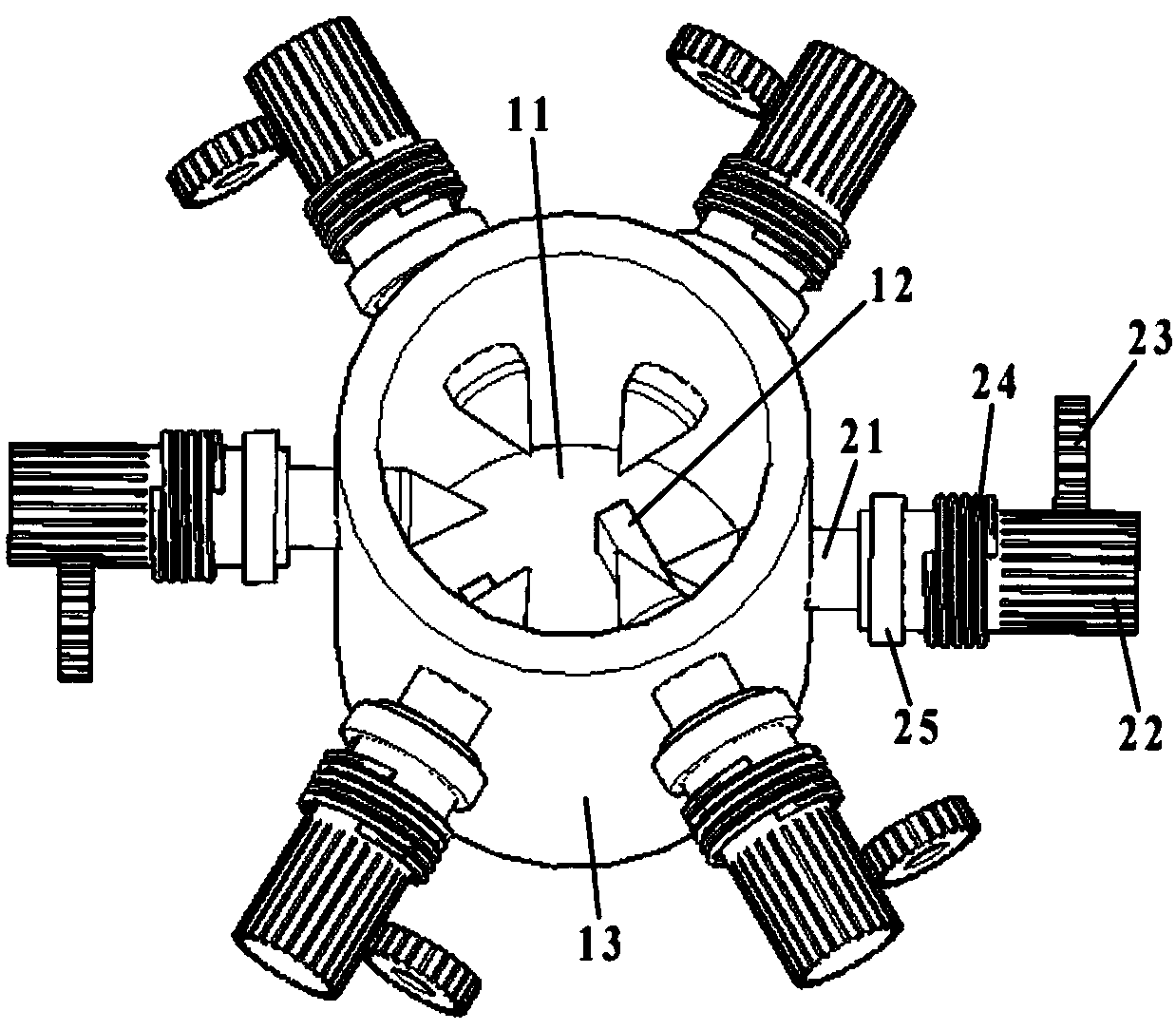

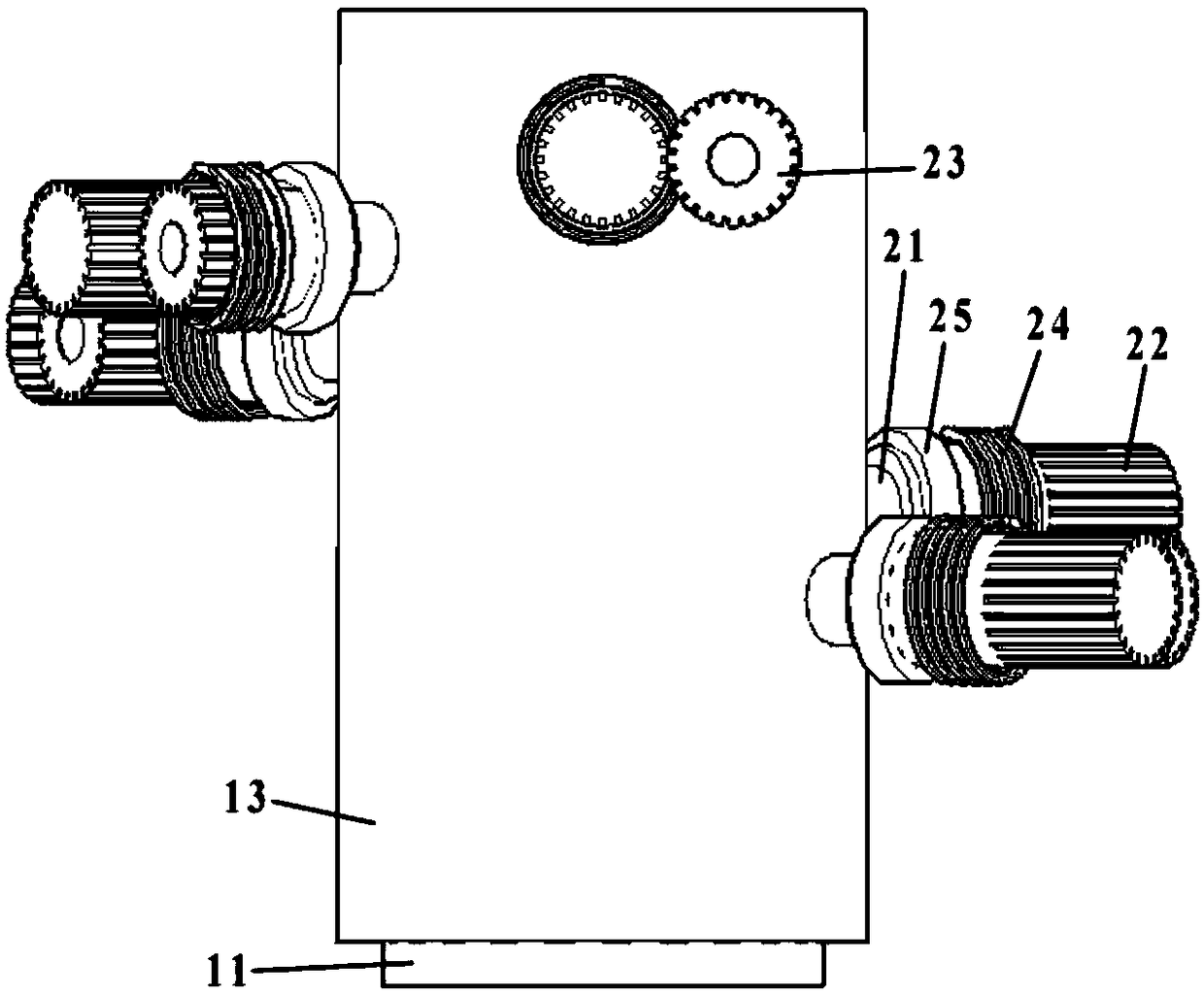

[0014] Such as figure 1 , figure 2 A kind of cinnabar handicraft processing device with multi-drill step distribution shown includes a base 11, a fixture tooling 12, a drill 21, an operating rod 22, a power tooth 23, and an electromagnetic coil 24; It can be lifted and installed, and the fixture tooling 12 is installed on the base 11; a plurality of drill bits 21 are arranged horizontally above the base 11, and the plurality of drill bits 21 are evenly distributed on the circumference of the vertical projection, and the drill bits 21 are all aligned with the center of the circumferential distribution , the height of a plurality of drill bits 21 is an arithmetic sequence; the rear end of the drill bit 21 is fixedly installed on the front end of the operating rod 22, and the outer ring of the rear end of the operating rod 22 is in ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap