Integrally-formed metal sealing bar

A technology for forming metal and seals, which is applied in the field of disposable locking tools, can solve problems such as strip slippage, and achieve the effects of preventing slippage, safe and reliable processing, and efficient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

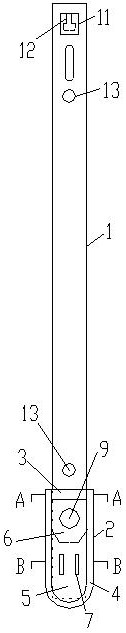

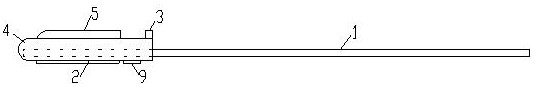

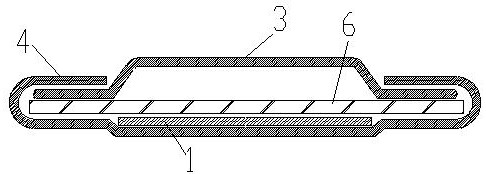

[0018] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, an integrally formed metal seal includes an iron lock bar 1 and a lock head 2. A lock groove 11 is provided at one end of the iron lock bar 1, and a lock tongue 12 is arranged in the lock groove 11. The lock end 2 is composed of an iron lock seat 4, The metal lock cover 5 and the lock plate 6 are composed of the other end of the iron lock bar 1 extending between the inner lock plate 6 of the lock head 2 and the iron lock seat 4, and the edge of the iron lock seat 4 is turned upwards to cover the edge of the iron lock cover 5 Riveted and pressed to seal, the top of the iron lock cover 5 is riveted downward to form two protrusions 7, the bottom of the iron lock seat 4 of the lock head 2 is riveted upward to form two protrusions 9, and the protrusions 9 pair with the iron lock bar 1. Fastening function, the front end of the lock head is provided with an insertion groove 3, and the edge of the iron lock seat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap