A high-level cargo pick-and-place device

A technology for picking and placing devices and goods, which is applied to storage devices, transportation and packaging, etc., can solve the problems of inability to guarantee safety, troublesome picking and placing of goods, high labor and equipment costs, and achieve safe and efficient picking and placing operations. Cost-effective, high-safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

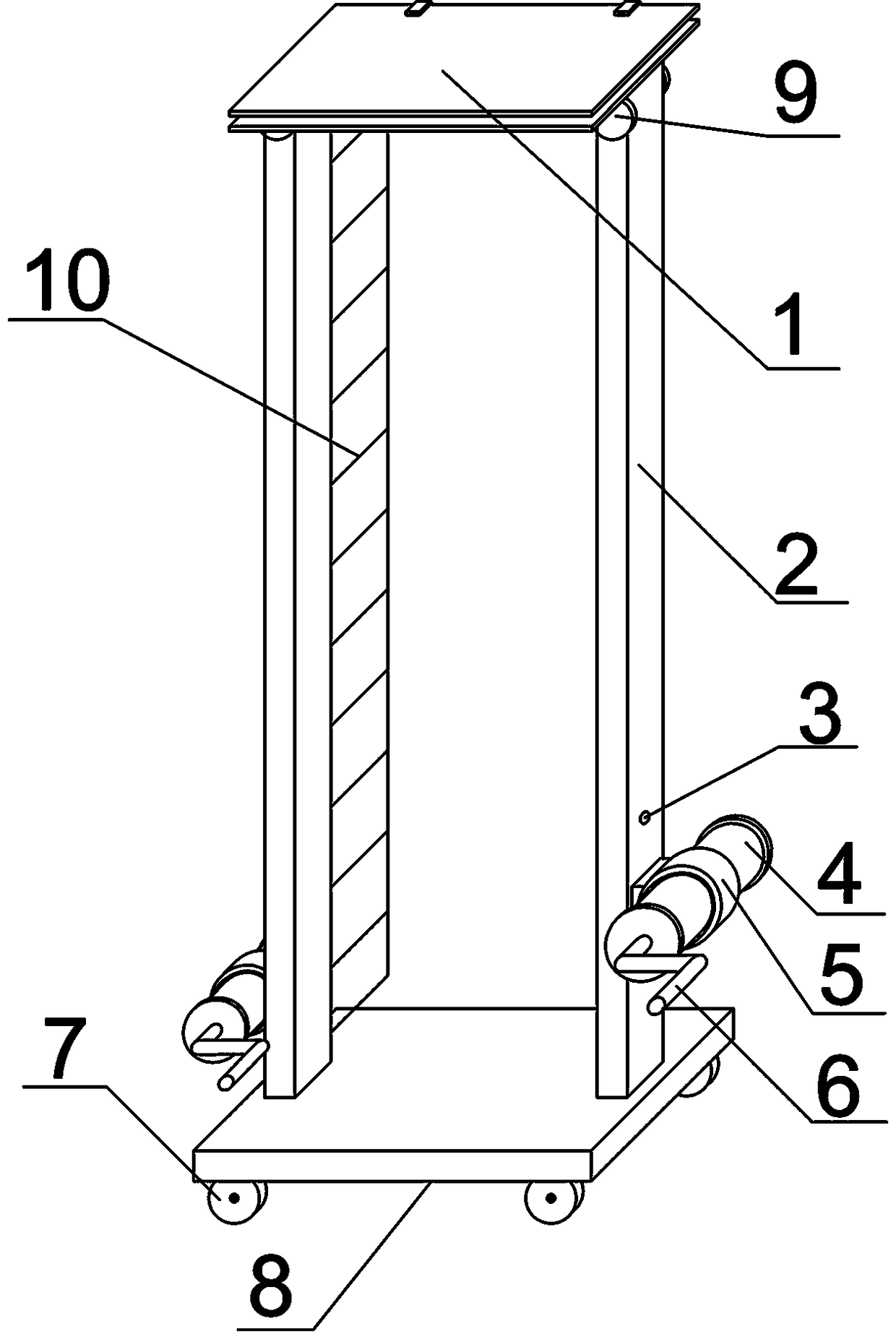

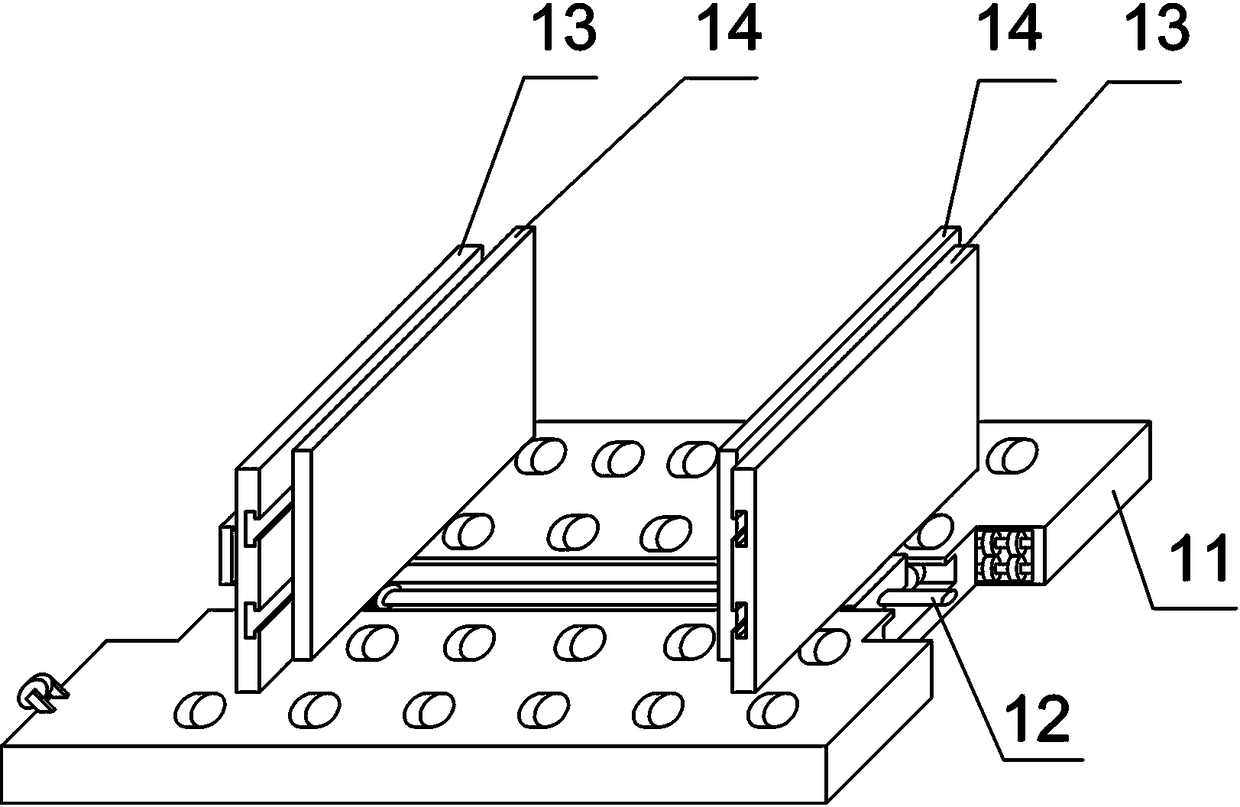

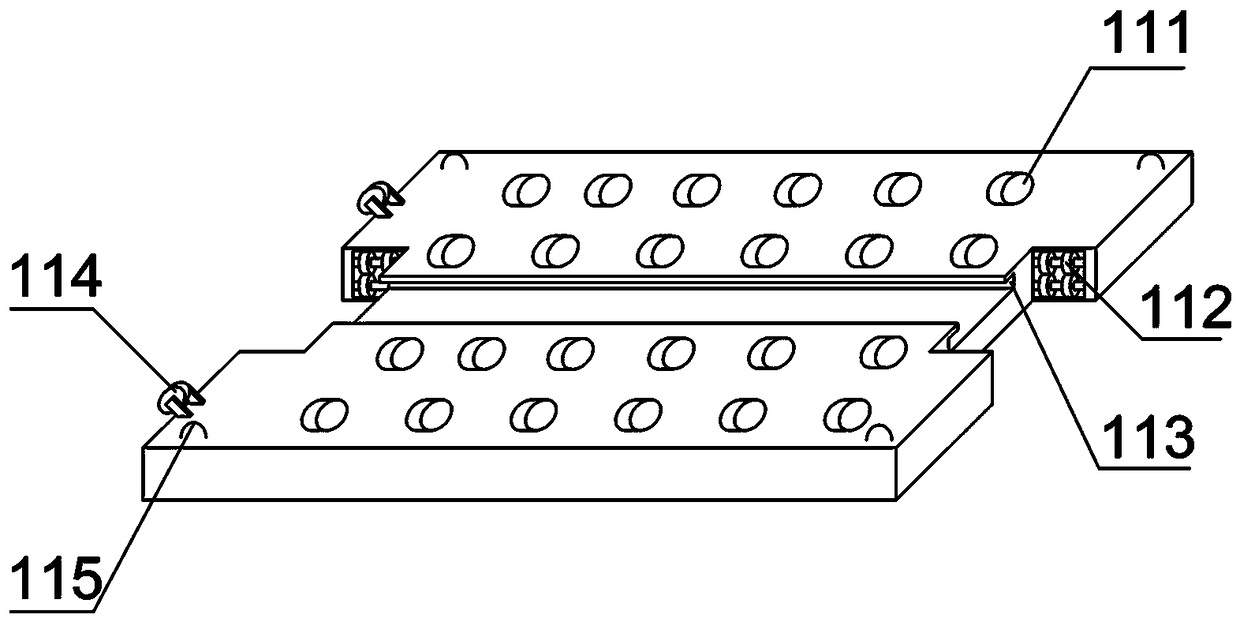

[0030] As shown in the figure, a high-level cargo pick-and-place device includes a bottom plate 8, and its feature is that two vertical main support rods 2 are symmetrically arranged on the upper surface of the bottom plate 8, and a first The fixed pulley 9 is provided with a bearing plate 11 between the two main support rods 2, four corners of the bearing plate 11 top surface are provided with fixed rings 115, and the bearing plate 11 top surface side is also provided with two symmetrically arranged first Two fixed pulleys 114;

[0031] A first T-shaped chute 113 is provided on the top surface of the load-bearing plate 11, and a clamping plate 13 and a transmission plate 14 are vertically provided at both ends of the load-bearing plate 11, and the clamping plate 13 at one end is a fixed plate 131, and the fixed plate 131 is fixedly connected with the load-bearing plate 11, and the clamping plate 13 at the other end is a movable plate 132, and a slider 134 cooperating with the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap