Micro-fluidic chip capable of producing two kinds of droplets including oil-water-oil droplets and water-oil-water droplets

A microfluidic chip, a technology for generating oil, which can be used in transportation and packaging, chemical instruments and methods, containers for laboratory use, etc., and can solve the problems of cumbersome surface modification process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

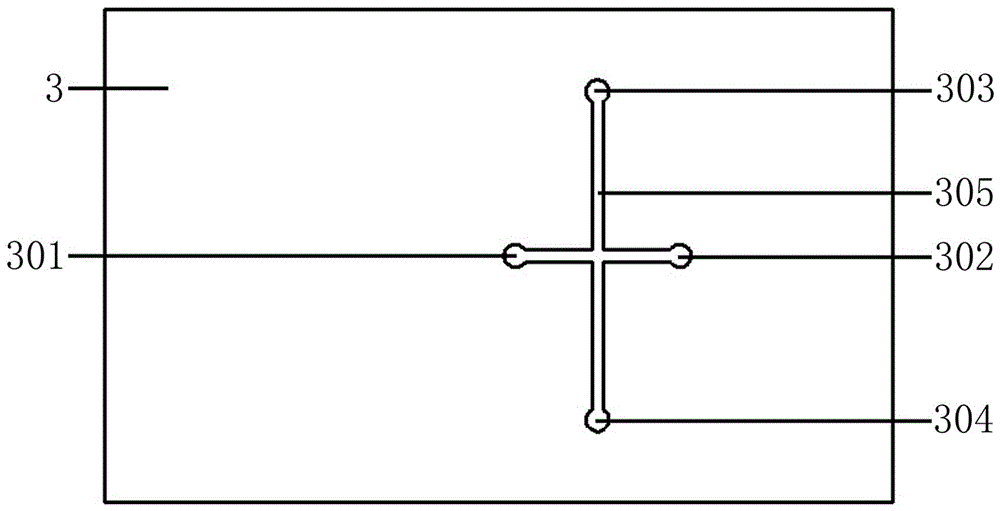

[0024] A microfluidic chip capable of generating oil-water-oil and water-oil-water droplets, including a first hydrophobic layer 1, a second hydrophobic layer 2, a first hydrophilic layer 3, and a second hydrophilic layer 4;

[0025] Wherein, the first hydrophobic layer 1, the second hydrophobic layer 2, the first hydrophilic layer 3, and the second hydrophilic layer 4 are sequentially stacked together from top to bottom;

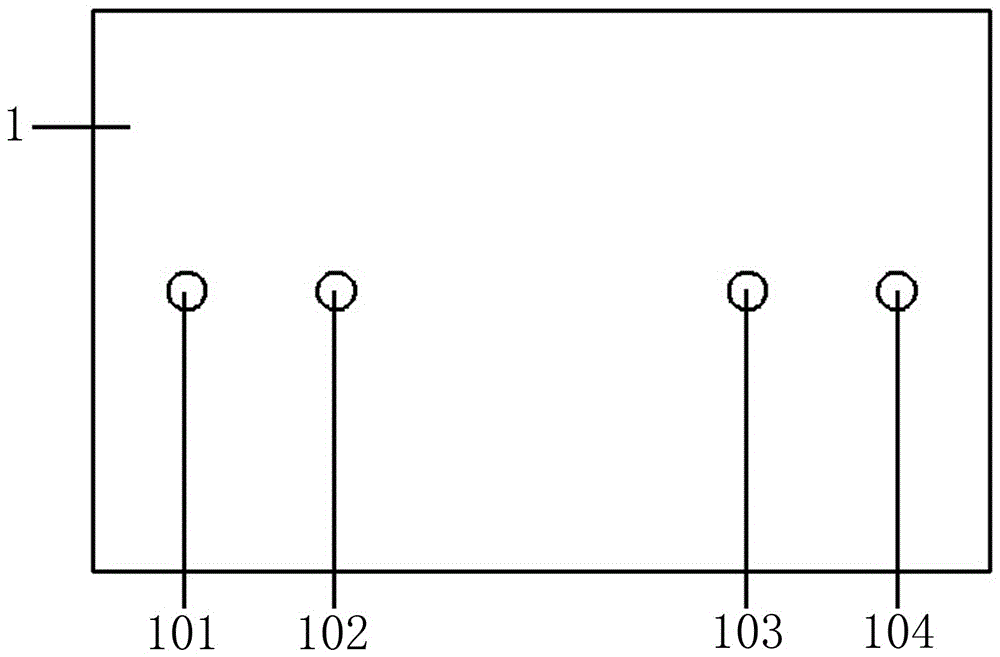

[0026] The surface of the first hydrophobic layer 1 is penetrated with a first through hole 101, a second through hole 102, a third through hole 103, and a fourth through hole 104;

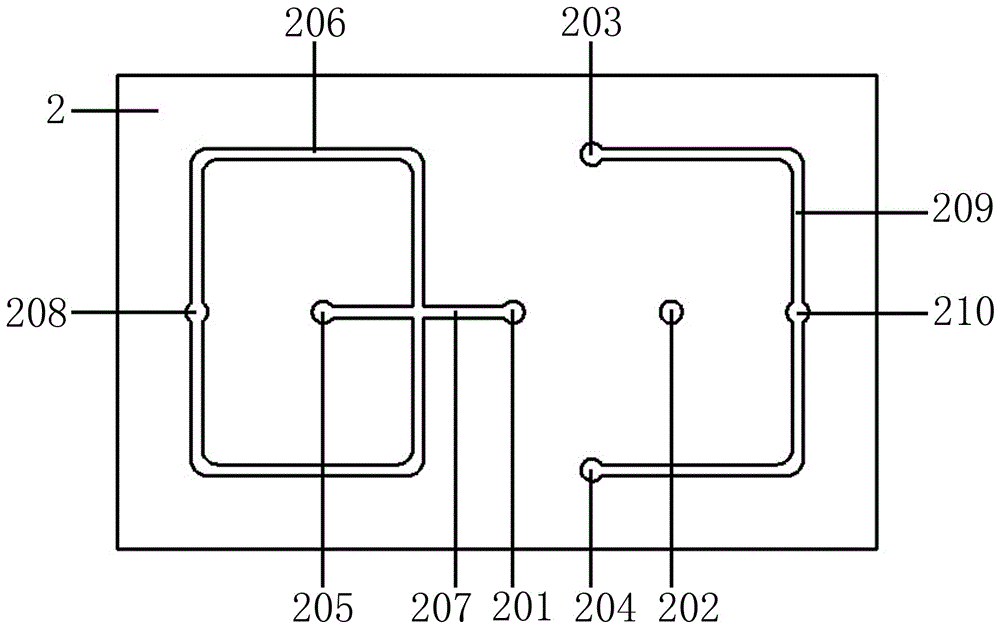

[0027] The surface of the second hydrophobic layer 2 is penetrated with a fifth through hole 201, a sixth through hole 202, a seventh through hole 203, and an eighth through hole 204;

[0028] The left part of the upper surface of the second hydrophobic layer 2 is provided with a first microchannel unit; the first microchannel unit includes a first circular concave hole 205, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com