Seat basin assembly of vehicle seat and vehicle seat including seat basin assembly

A technology for car seats and bidets, which is applied to vehicle seats, seat frames, movable seats, etc., can solve the problems of high-strength seat frame, heavy weight, complicated process, and a large number of parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

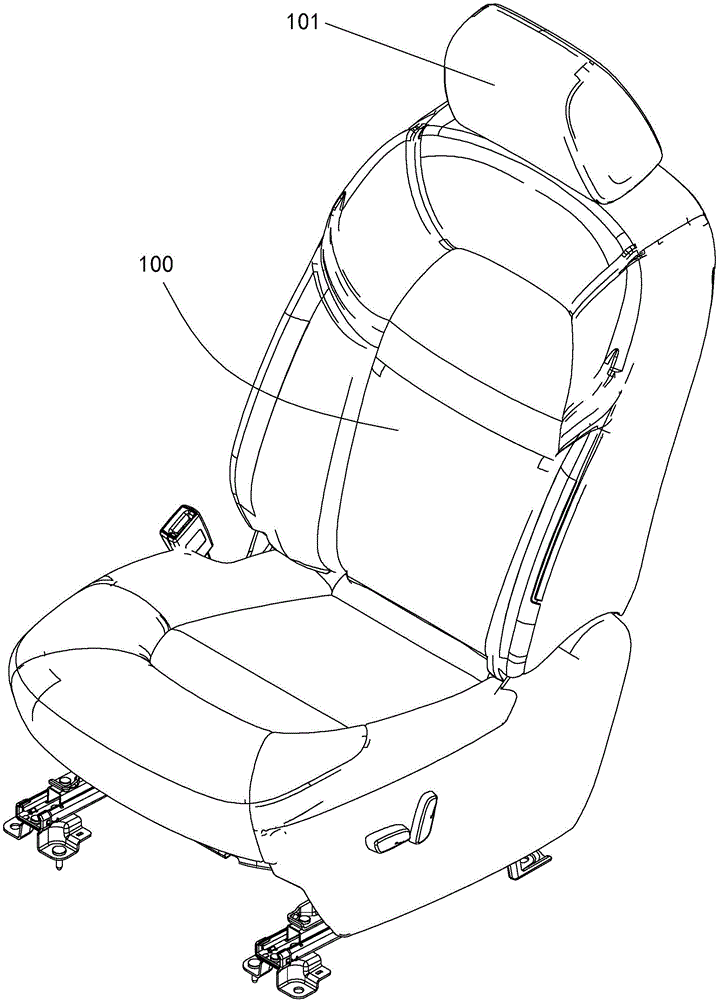

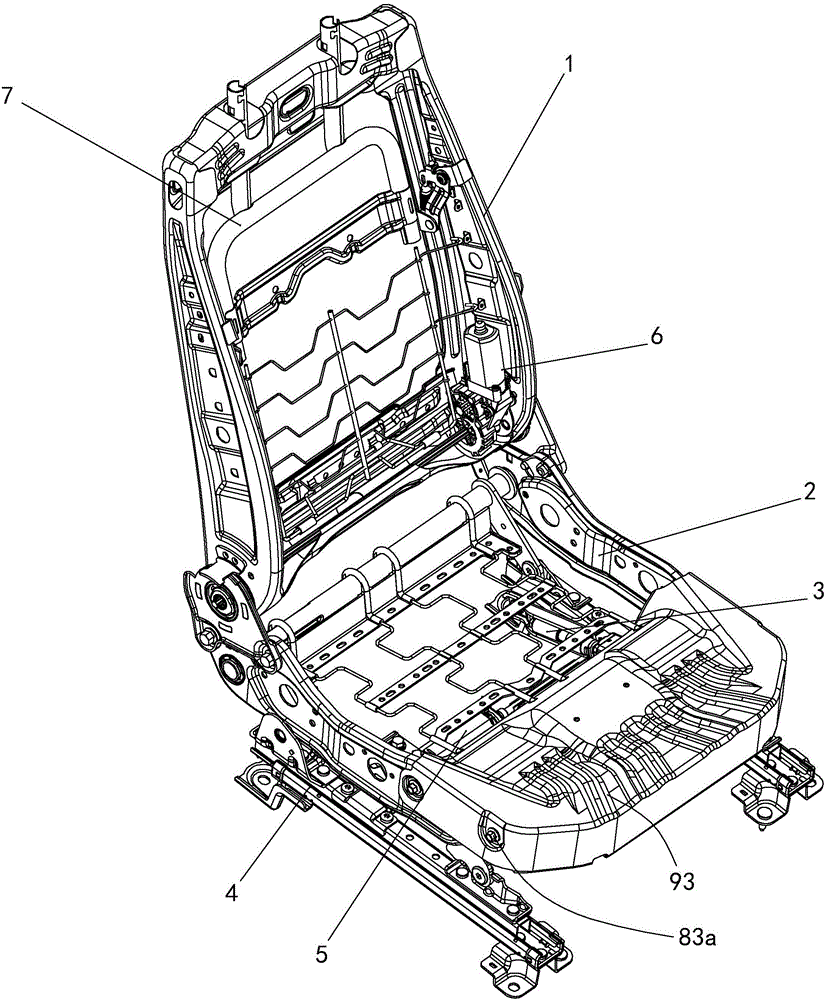

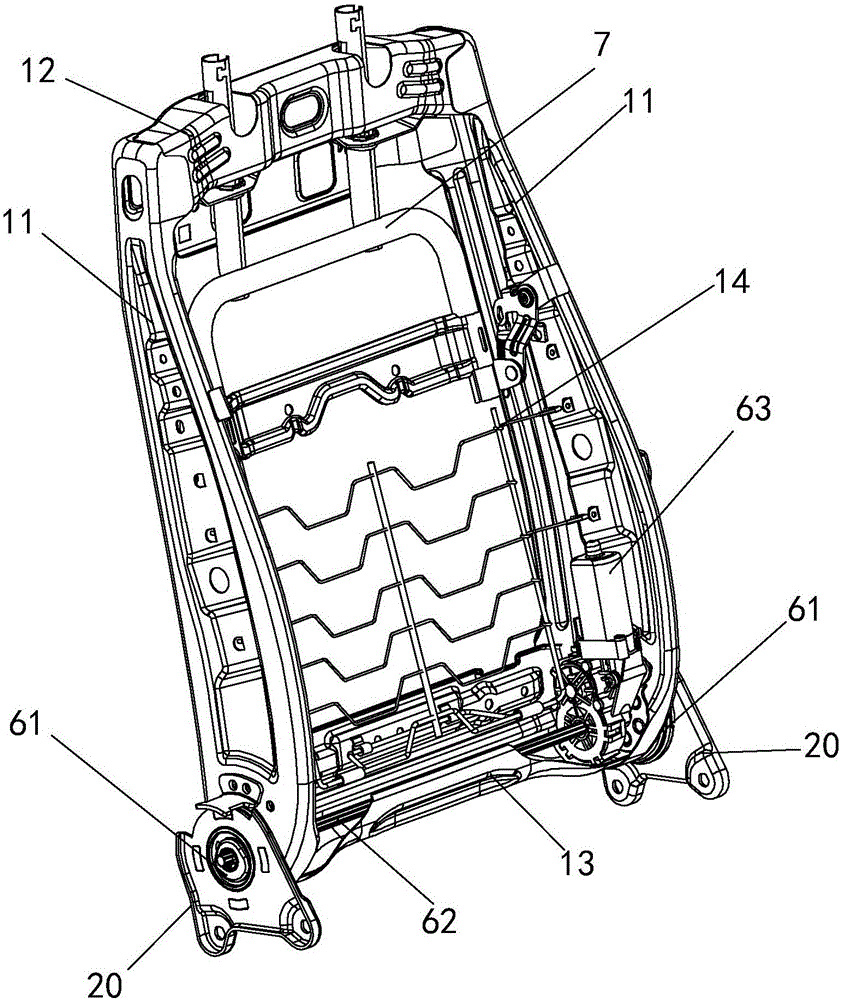

[0039] Such as Figure 1 to Figure 10 The car seat shown includes a seat frame, an outsourcing chair cover 100 and a headrest 101, the outsourcing chair cover 100 covers the seat frame as a whole, and the seat frame includes a backrest frame 1, a seat cushion frame 2, and a seat cushion frame The connecting plate 20 and the seat pan 9, the backrest frame 1 is arranged vertically as a whole, the seat cushion frame 2 is arranged horizontally as a whole, the seat cushion frame 2 is fixedly connected with the seat cushion frame connecting plate 20, and the seat cushion frame connecting plate is supported on the seat cushion frame 2 on.

[0040] The seat frame in this embodiment also includes an electric angle adjustment device 6, an electric lifting device 3, a slideway device 4, an electric slideway drive device 5, an active safety headrest device 7 and an electric seat basin angle adjustment device 8. The active safety headrest device 7 is installed on the upper part of the bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com