Rotary knob type drive-by-wire gear shifter

A shift-by-wire, knob-type technology, applied in the control device, transmission control, components with teeth, etc., can solve the problems of occupying a large cockpit space, affecting the appearance, reducing driving comfort, etc. Conducive to the effect of light weight and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further elaborated below in conjunction with specific drawings and specific embodiments. The present invention can also have other embodiments. All equivalent substitutions or equivalent transformations formed by those skilled in the art without departing from the principles of the present invention through changes and modifications all fall within the scope of protection required by the present invention.

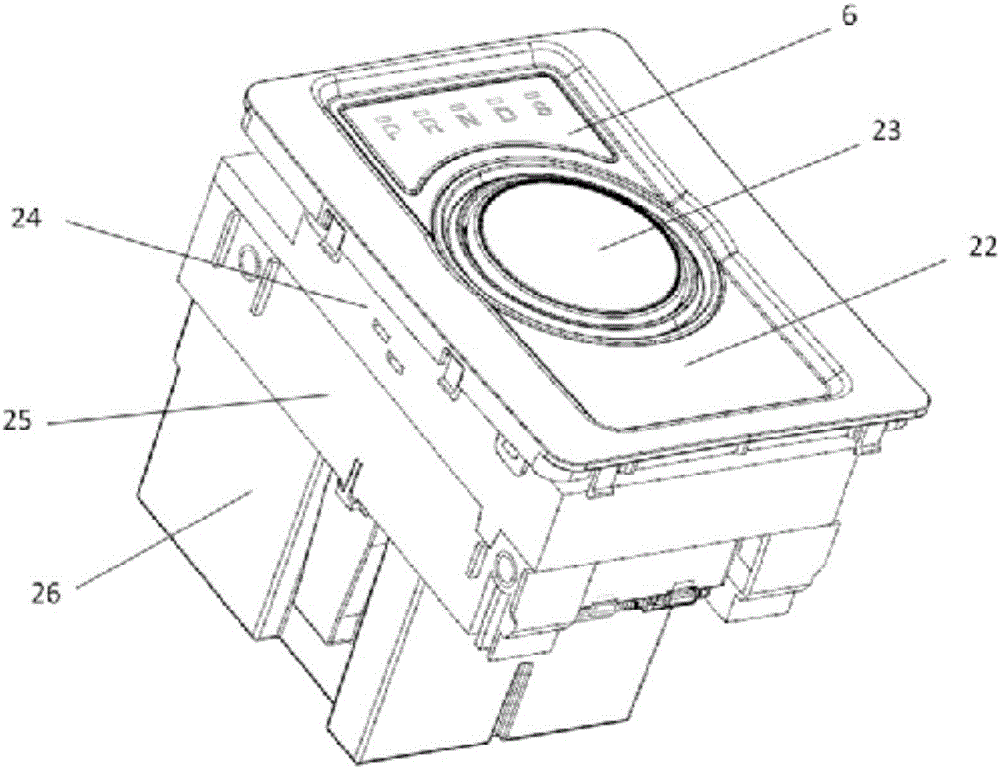

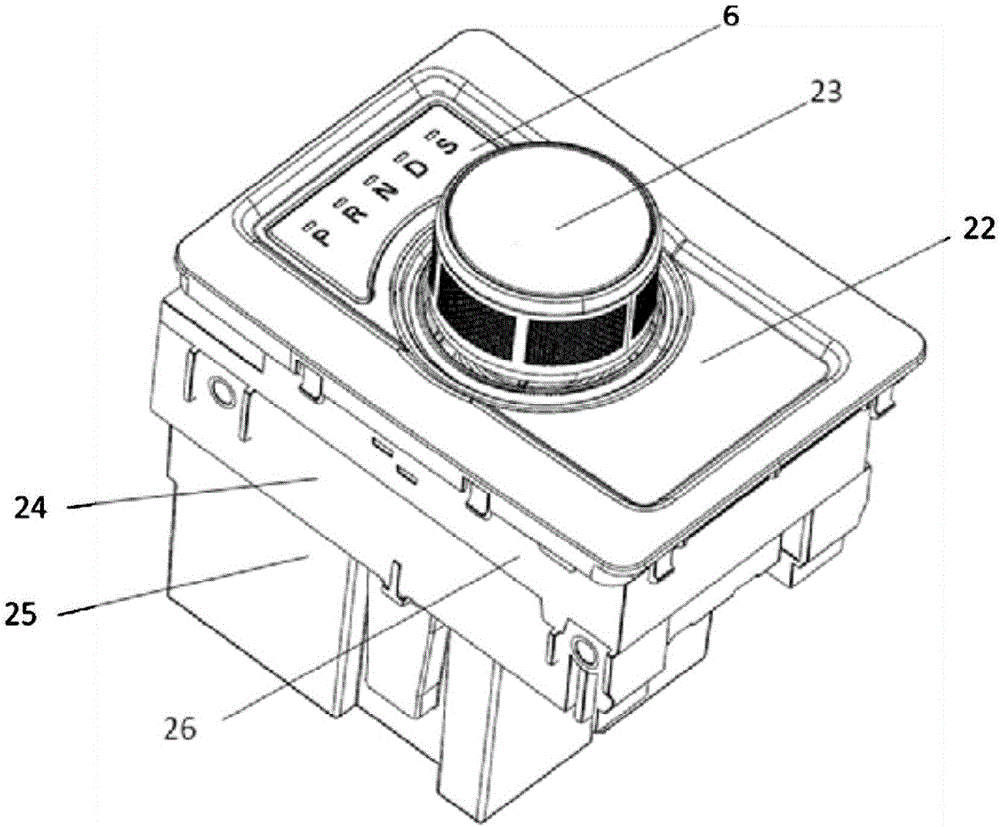

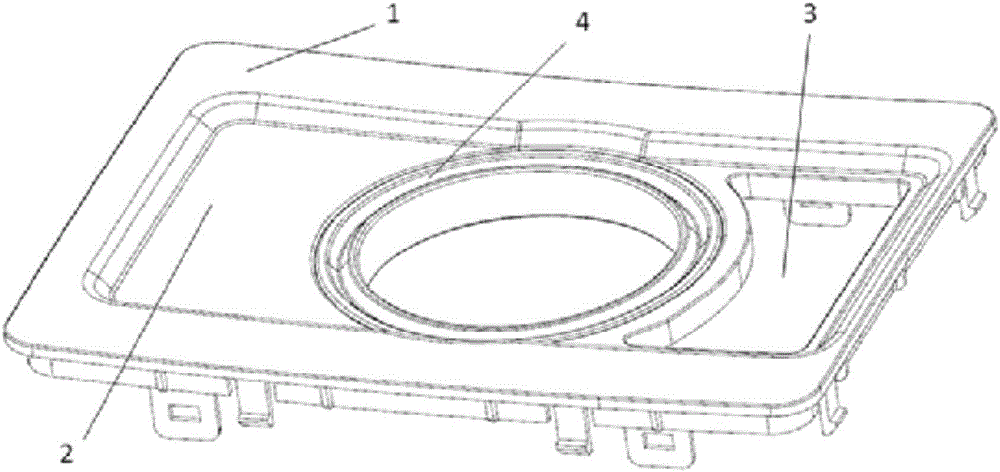

[0032] refer to figure 1 It is the overall appearance diagram of the knob-by-wire shifter of the present invention (the shift knob is in the descending position), refer to figure 2 The external view of the knob-type shifter by wire of the specific example of the present invention (the shift knob is in the rising position), refer to image 3 For a panel view of the knob-by-wire shifter, refer to Figure 4 It is the upper side view of the upper housing and the light board of the knob-type shifter by wire, refer to Figure 5 It is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com