L-shaped radiation boiler capable of reducing high-alkalinity coal combustion contamination

A high-alkaline, boiler technology, used in steam boilers, steam superheating, lighting and heating equipment, etc., can solve problems such as increased operating costs, contamination of flow heating surfaces, and leakage of high-temperature reheaters and high-temperature superheaters. , to achieve the effect of reducing the contamination problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

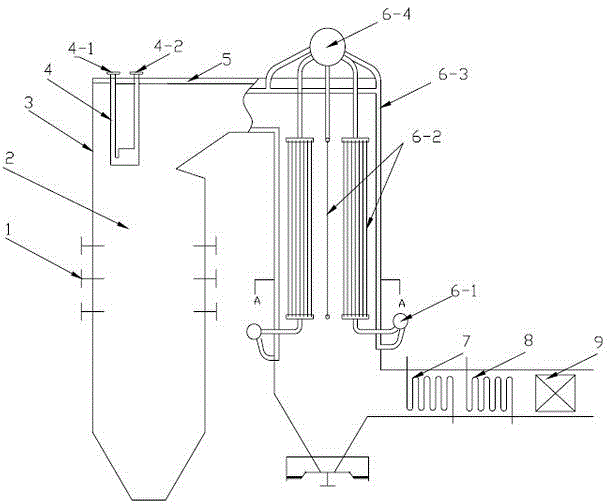

[0031] The furnace part involved in the present invention is basically the same as the traditional π-type boiler. The arrangement of the convection heating surface is cancelled, and an L-shaped radiation boiler is added. The special arrangement of the radiation heating surface of the radiation boiler reduces the erosion of the flue gas on the heating surface. And because of its low flow velocity, ash deposits are not easy to occur, which can reduce the pollution caused by burning high-alkaline coal.

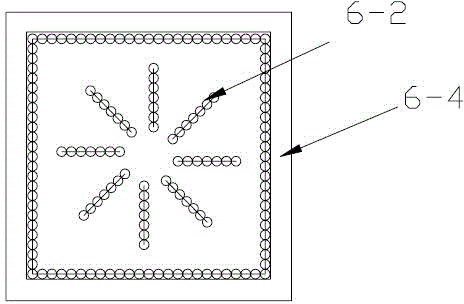

[0032] Such as Figure 1-2 As shown, the L-shaped radiant boiler is a π-shaped boiler, including a combustion furnace 2 and a radiation furnace. The combustion furnace 2 is connected to the radiation furnace through a horizontal flue; device 5, to prevent the high-temperature flue gas from being contaminated in advance above the combustion furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com