A kind of cfb-beam radiant boiler for reducing pollution of high alkalinity coal

A high-alkaline and boiler technology, which is applied to steam boilers, fuels that burn in a molten state, and combustion types, etc., can solve problems such as increased operating costs, large demand, contamination and dust accumulation on the flow heating surface, and achieve pollution reduction problem effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

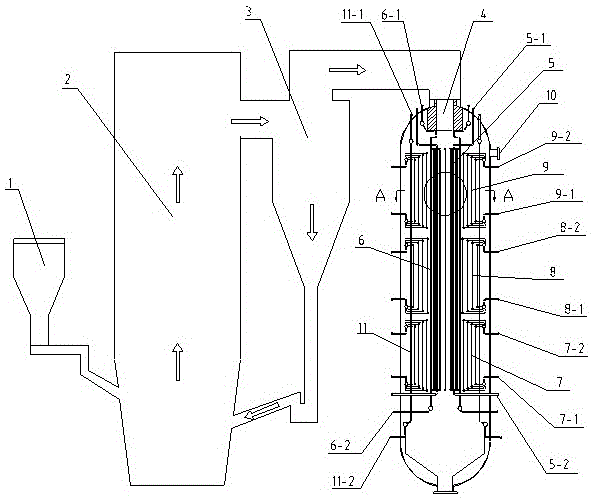

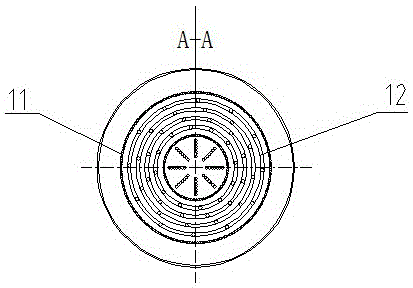

[0030] Such as figure 1 As shown, a CFB-beam radiant boiler that reduces the pollution of highly alkaline coals includes a CFB boiler, a separation device and a beam radiant boiler. The upper and lower ends of the side walls of the CFB boiler are provided with passages communicating with the separation device. The top of the separation device is connected with a high-temperature flue, and the high-temperature flue is connected with a beam-shaped radiation boiler; the beam-shaped radiation boiler includes a radiation heat exchange part, a convection heat exchange part and a shell, the radiation heat exchange part is located in the middle of the shell, and the convection heat exchange part is located in the middle of the shell. The heat part is located between the radiation heat exchange part and the shell. There is a flue gas channel on the top of the shell. The flue gas channel communicates with the high-temperature flue. part.

[0031] The separation device is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com