Clamp type pot cover opening and closing structure

An opening and closing structure, clamp-type technology, applied in pressure cookers, cooking utensils, household utensils and other directions, can solve the problems of smooth operation, loose parts, loose fit, etc., to improve safety, reduce occupied space, close-fitting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

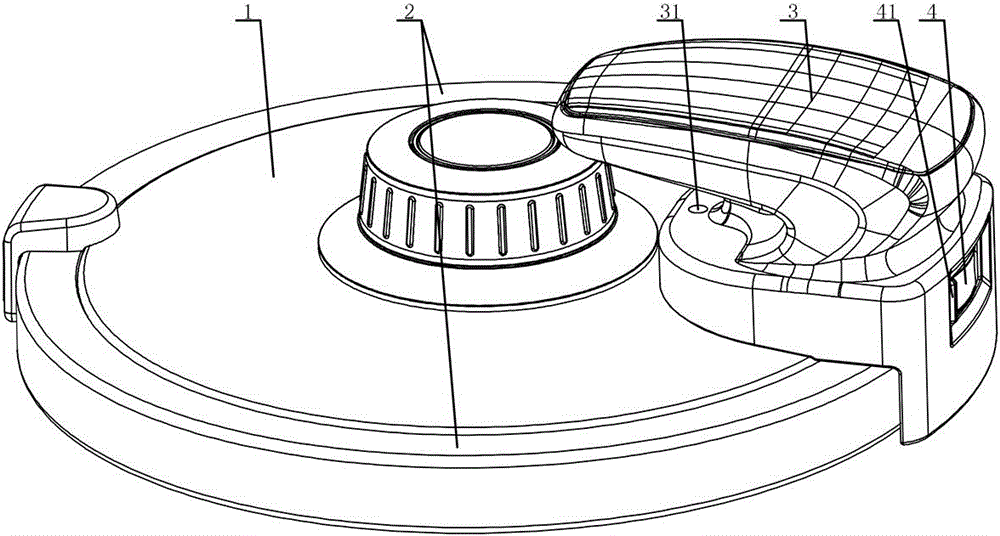

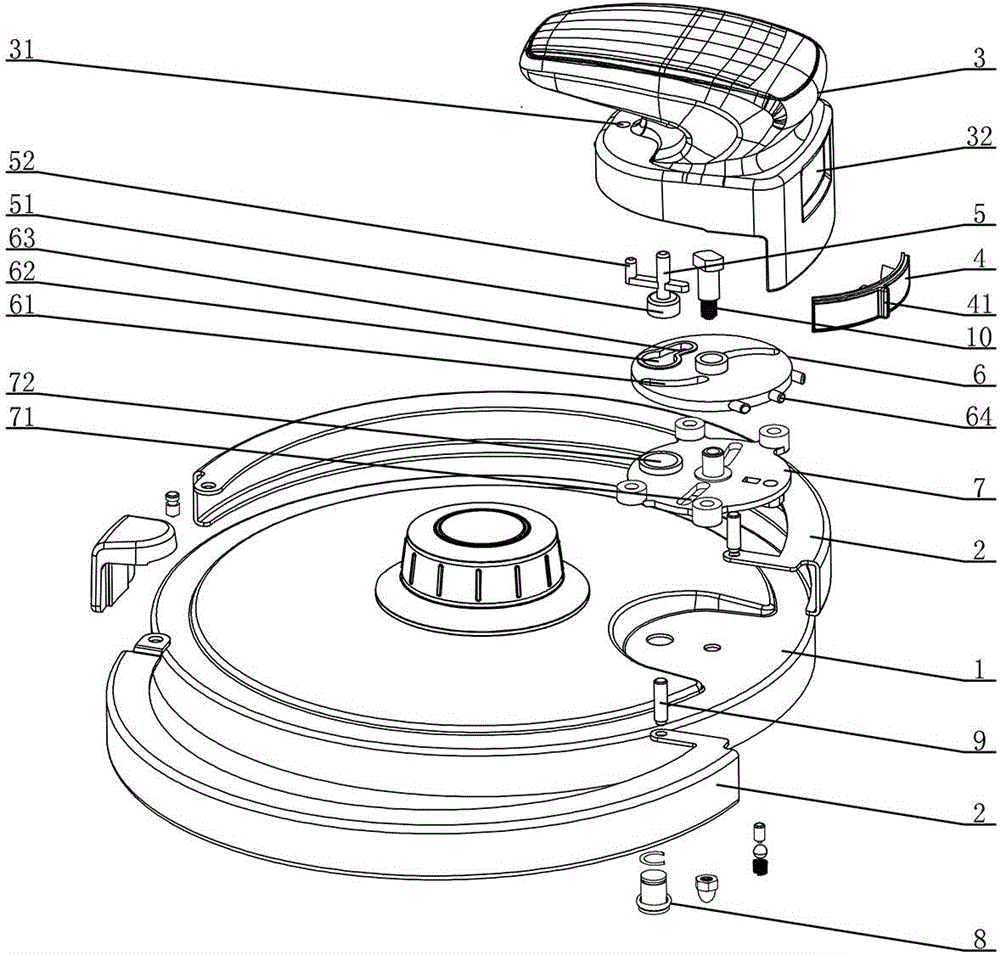

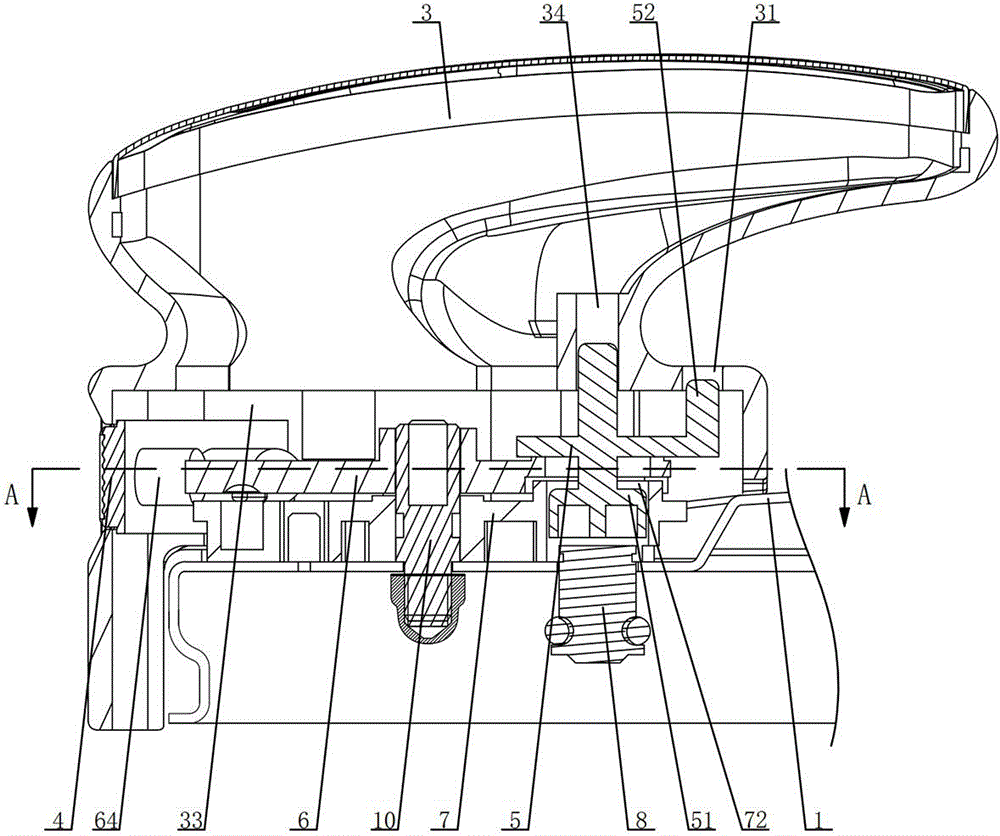

[0027] Such as Figure 1 to Figure 8 As shown, a clamp type pot cover opening and closing structure includes a pot cover 1, at least two sets of clamps 2, each guide column 9 corresponding to each set of clamps 2, a handle 3, a rotary knob 4, and a sheave 6. Safety valve 8, the bottom of the safety valve 8 is set on the pot cover 1, one end of each set of clamps 2 is rotationally connected to one side of the pot cover 1, and the other end of each set of clamps 2 is located on the other side of the pot cover 1 One side is connected with the guide post 9 respectively, and also includes a fixed plate 7 and an anti-opening rod 5. The handle 3 is arranged on one side of the pot cover 1 and an accommodating cavity 33 is arranged in the handle 3. The fixed plate 7 is located in the accommodating cavity 33 and the sheave 6 is rotated and placed on the fixed plate 7. The fixed plate 7 is respectively provided with a limit slot 71 corresponding to the guide post 9 and a stop rod 5 Corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com