A permeable refrigerant booster station

A pressurization station and air-permeable technology, applied in the field of air-permeable refrigerant booster stations, can solve problems such as hidden dangers in production safety, flammability, waste of refrigerant, etc., and achieve the effect of improving the discovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

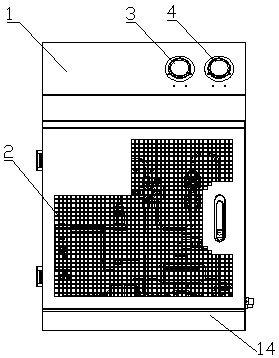

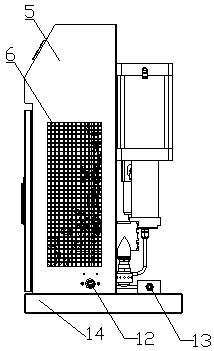

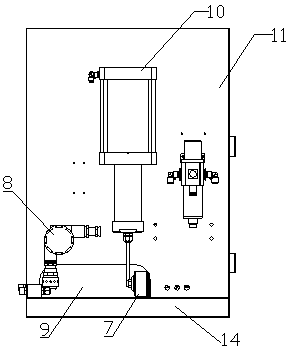

[0014] Such as Figure 1-3 As shown, a permeable refrigerant booster station in this embodiment includes a permeable cabinet main body 1, and a pneumatic booster pump 7 and a shut-off valve (not shown in the figure) are installed in the permeable cabinet main body 1. ), an exhaust valve (not shown in the figure); the main body 1 of the permeable cabinet is surrounded by a permeable front door 2, a permeable left and right side 5, a permeable back wall 11 and a base 14; the permeable The hollow front door 2 is a grid-shaped hollow hollow front door; the hollow left and right sides 5 are grid-shaped hollow hollow left and right sides; the hollow back wall 11 is opened with a The air-permeable back wall of through hole 9.

[0015] A pressure gauge 3 before boosting and a pressure gauge 4 after boosting are installed on the through-type front door 2 of the through-type cabinet main body 1; Cylinder 10, the leak detection sensor 8 is installed near the bottom through hole 9 on th...

Embodiment 2

[0018] Such as Figure 1-3 As shown, a permeable refrigerant booster station in this embodiment includes a permeable cabinet main body 1, and a pneumatic booster pump 7 and a shut-off valve (not shown in the figure) are installed in the permeable cabinet main body 1. ), an exhaust valve (not shown in the figure); the main body 1 of the permeable cabinet is surrounded by a permeable front door 2, a permeable left and right side 5, a permeable back wall 11 and a base 14; the permeable The hollow type front door 2 is a hollow type front door for which a square through hole is opened on the through hole, and a steel wire mesh is welded on the through hole; The air-permeable left and right sides of the net; the air-permeable rear wall 11 is the air-permeable rear wall with through holes 9 at the bottom.

[0019] A pressure gauge 3 before boosting and a pressure gauge 4 after boosting are installed on the through-type front door 2 of the through-type cabinet main body 1; Cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com