Tool of manual rapid fire bending handle

A simmering handle and fast technology, which is applied in the field of tooling for manual rapid simmering handles, can solve the problems of slow simmering and difficult angle control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

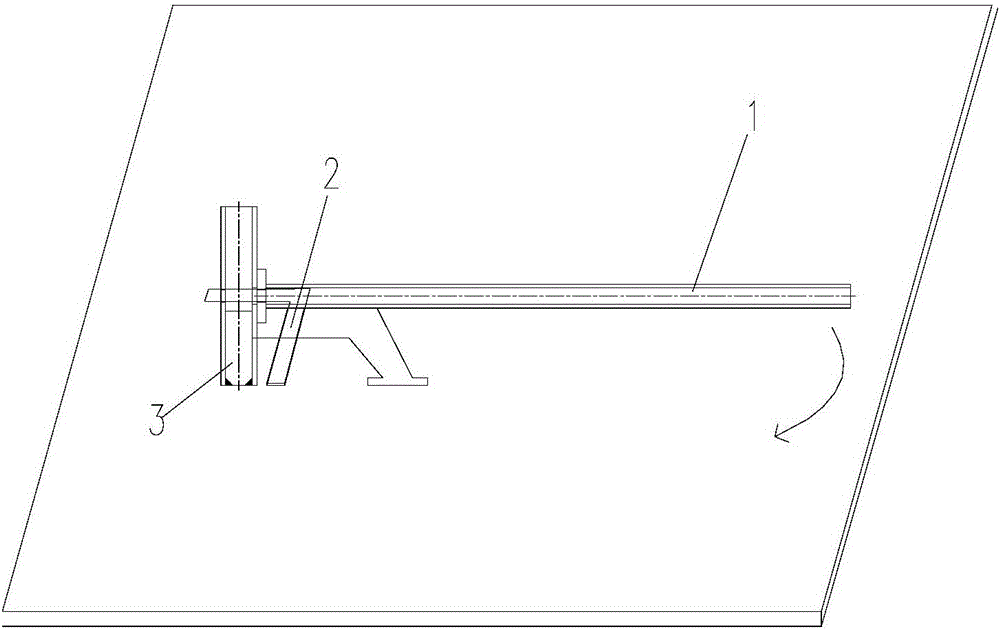

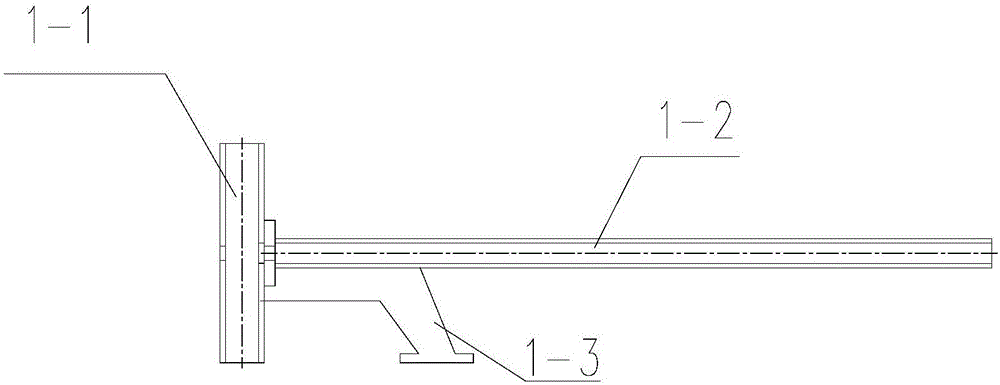

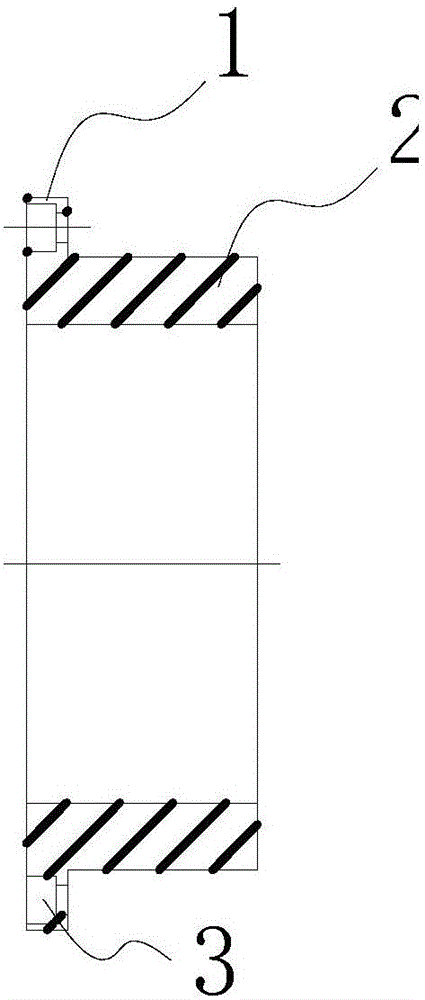

[0018] see Figure 1 to Figure 3 , a tool for manual rapid heating and simmering handles, comprising:

[0019] A positioning column 3 fixedly connected to the workbench;

[0020] The simmering main handle 1 socketed on the positioning column 3; the simmering main handle 1 includes a hollow tube 1-1, a handle tube 1-2, and a push handle 1-3; wherein: the hollow tube 1 -1 is socketed on the above-mentioned positioning column 3, and one end of the handle pipe 1-2 is fixedly connected with the hollow pipe 1-1 through the positioning pin shaft 2; one end of the above-mentioned push handle member 1-3 is fixedly connected with the hollow pipe 1-1 ; The other end of the above-mentioned push handle parts 1-3 is located on the upper surface of the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com