Glass Mold Smart Polisher

A glass mold and polisher technology, applied in grinding/polishing equipment, manufacturing tools, grinding machines, etc., can solve the problem of low applicability and achieve the effect of strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by means of specific embodiments:

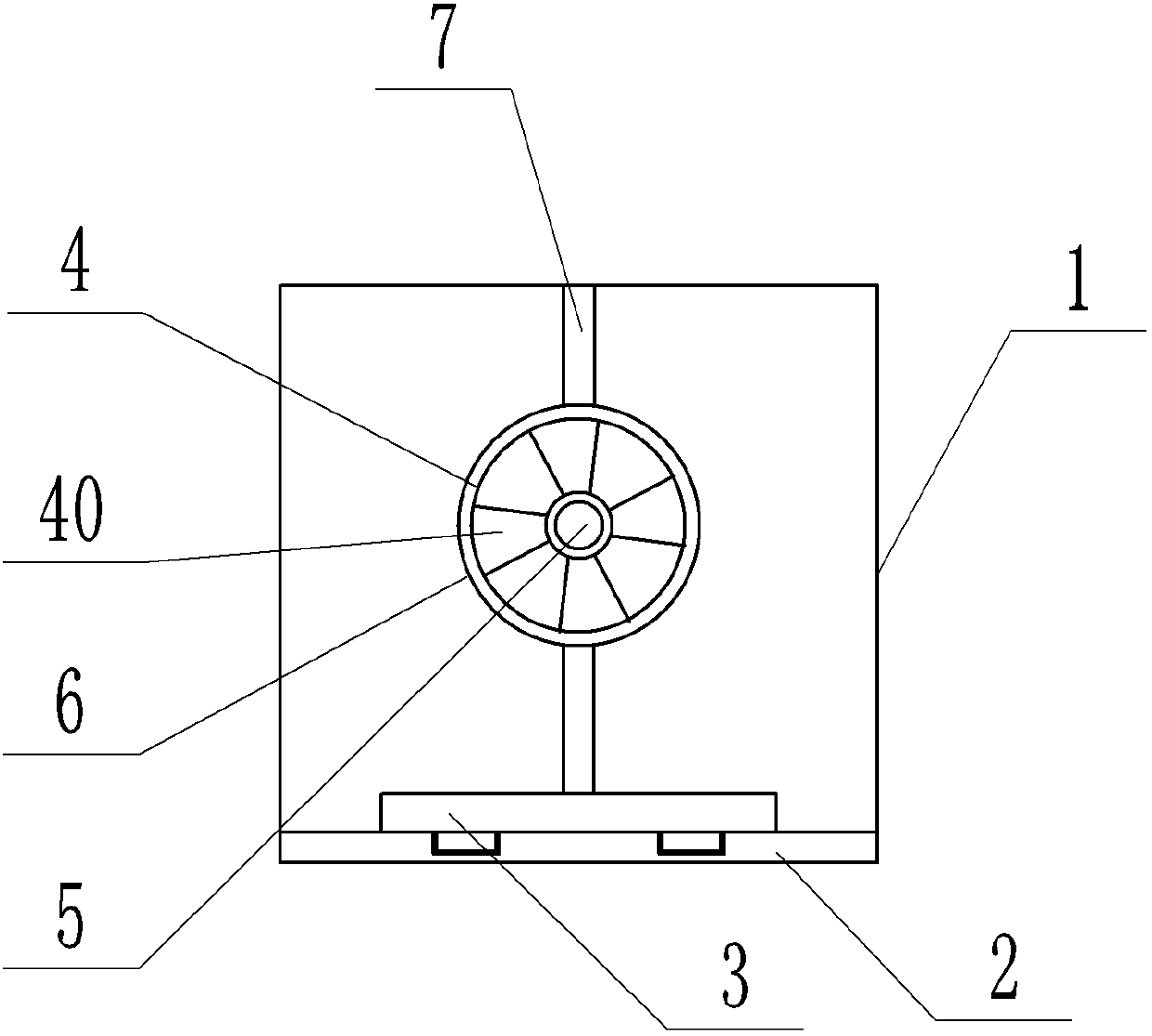

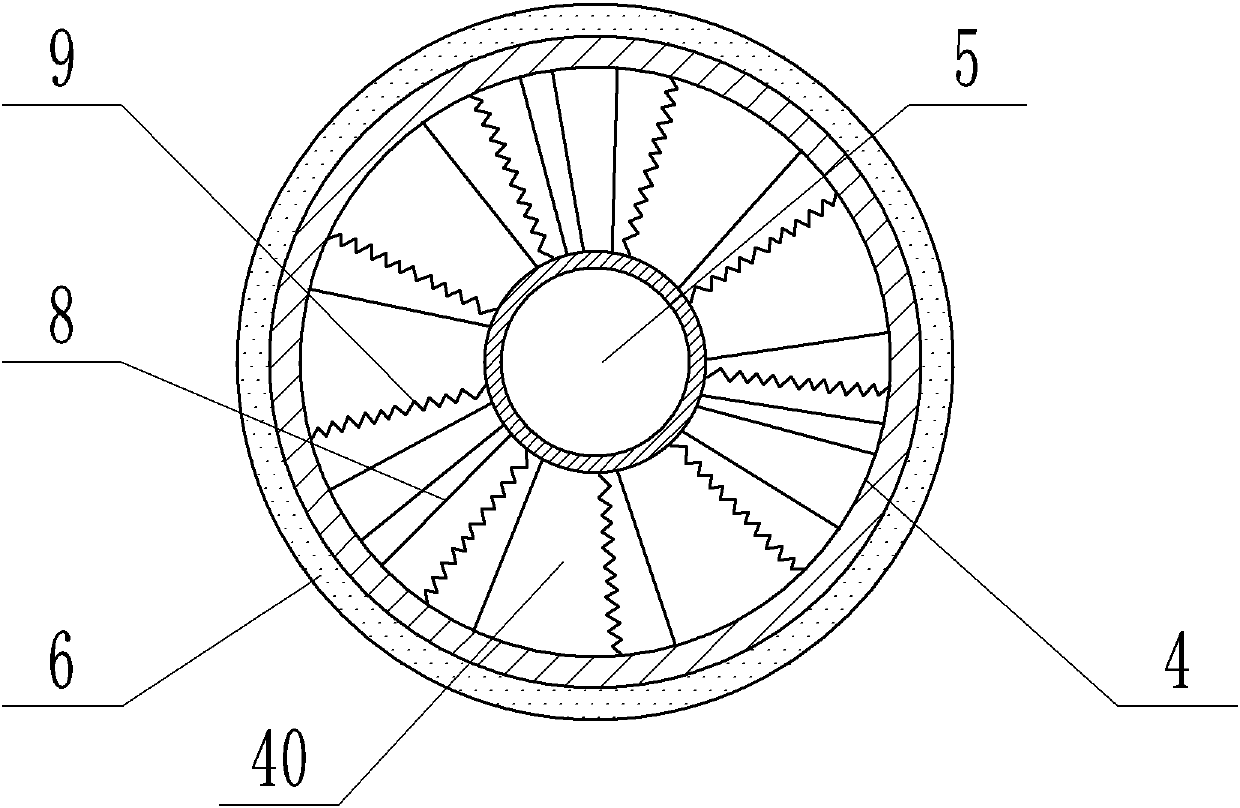

[0015] The reference signs in the accompanying drawings include: frame 1 , bottom plate 2 , moving bracket 3 , roller 4 , arc block 40 , rotating shaft 5 , abrasive layer 6 , guide rail 7 , support rod 8 , and spring 9 .

[0016] The embodiment is basically as attached figure 1 Shown: Glass mold intelligent polisher, including frame 1 and bottom plate 2, frame 1 is installed on bottom plate 2, and also includes mobile bracket 3, bottom plate 2 is provided with grooves, and mobile bracket 3 is provided with protrusions corresponding to the grooves , the mobile bracket 3 can slide along the groove of the bottom plate 2, a guide rail 7 is welded on the top of the mobile bracket 3, the upper end of the guide rail 7 is connected to the upper end of the frame 1, and the roller 4 is slidably connected to the guide rail 7, and the roller 4 includes several arc blocks 40. Includi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap