Clamping parts for easy piece-by-piece extraction from the rack

A piece-by-piece technology for clamping parts, applied in the field of clamping parts, can solve problems such as unreliability, dropping, and difficulty in ensuring that trays are pulled out one by one, achieving the effect of ensuring reliability and reducing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

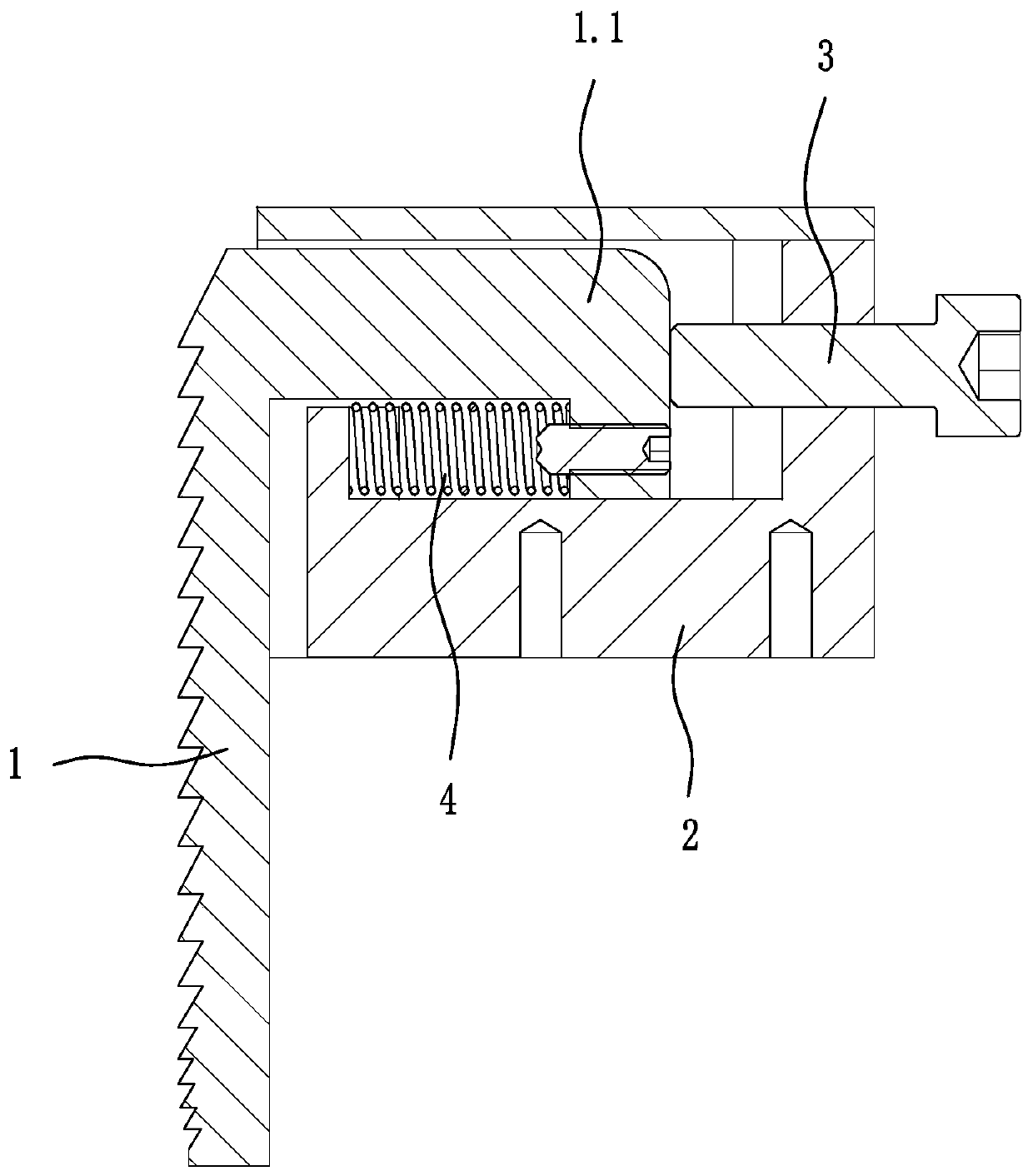

[0009] like figure 1 As shown, a clamping part that is convenient to be pulled out piece by piece from the warehouse rack includes a rack 1 extending downward and a seat 2 for installing the rack 1. The rack 1 has a content accommodated in the seat 2. Set Section 1.1. In the present invention, there is a gap between the rack 1 and the seat body 2 to accommodate the rack 1 to swing perpendicular to the tooth surface, so that only the top of the accommodating part 1.1 and the seat body 2 and the rack There is a gap between the rack and the seat to allow the rack to swing. The base body 2 is equipped with a limiter 3 that touches the end of the accommodating portion 1.1 of the rack 1, and the bottom of the warehouse frame (common components, not shown in the figure) The racks 1 on both sides of the outlet cannot move on both sides, so as long as the installation positions of the clamping parts on both sides are adjusted according to the size specifications of the objects on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com