Waste collection device

A waste collection and waste technology, applied in the fields of magnetic separation, solid separation, chemical instruments and methods, etc., can solve problems such as affecting the cleanliness of the site and product quality, affecting product quality, and major safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing.

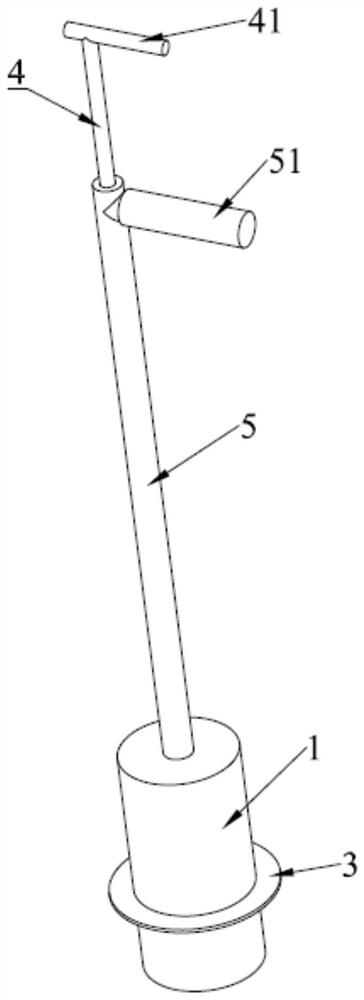

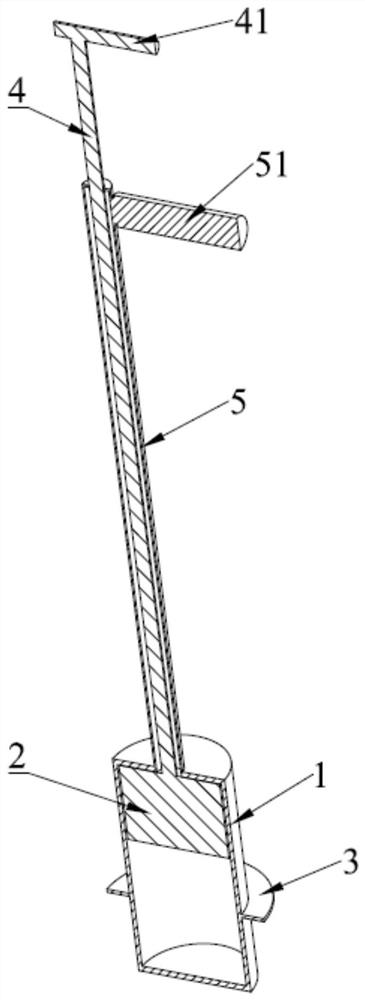

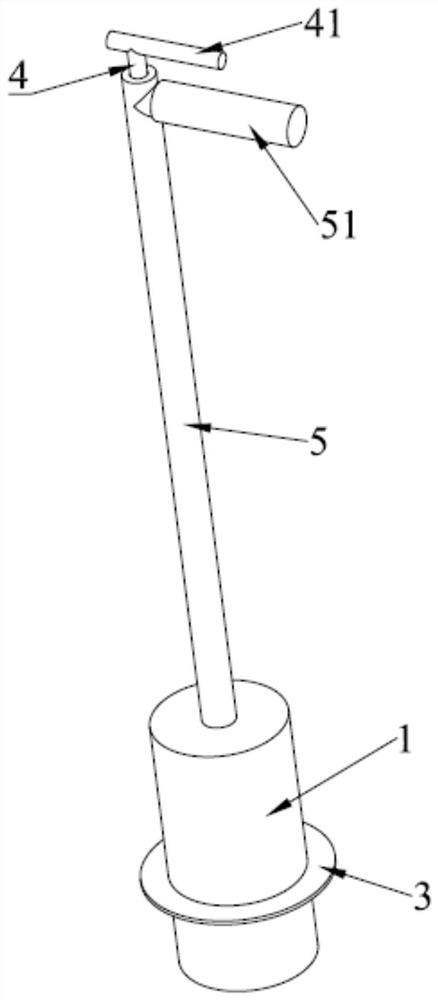

[0028] The invention provides a waste collecting device, which is especially suitable for stamping waste of sheet metal. Such as Figure 1-4 As shown in , the waste collection device of the present invention includes a housing 1 and a magnetic adsorption device 2, wherein the housing 1 has a collection site that can be used to collect waste materials, the magnetic adsorption device 2 is movably arranged in the housing 1, and the magnetic The distance between the adsorption device 2 and the collection part is changed, so that the collection part can realize suction and discharge.

[0029] The structure of the waste collection device of the present invention is simple, and by changing the position of the magnetic adsorption device 2 in the housing 1, the strength of the magnetic field at the collection part of the housing 1 can be adjusted, thereby realizing automatic waste ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com