Roller shutter expansion type rotary kiln adjustable bricklaying machine

A brick laying machine and rotary kiln technology, applied in the field of masonry machinery, can solve the problems of inconvenient operation, unbalanced kiln wall pressure, rising price and cost, etc., and achieve the effects of large adjustable strength, wide application range and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

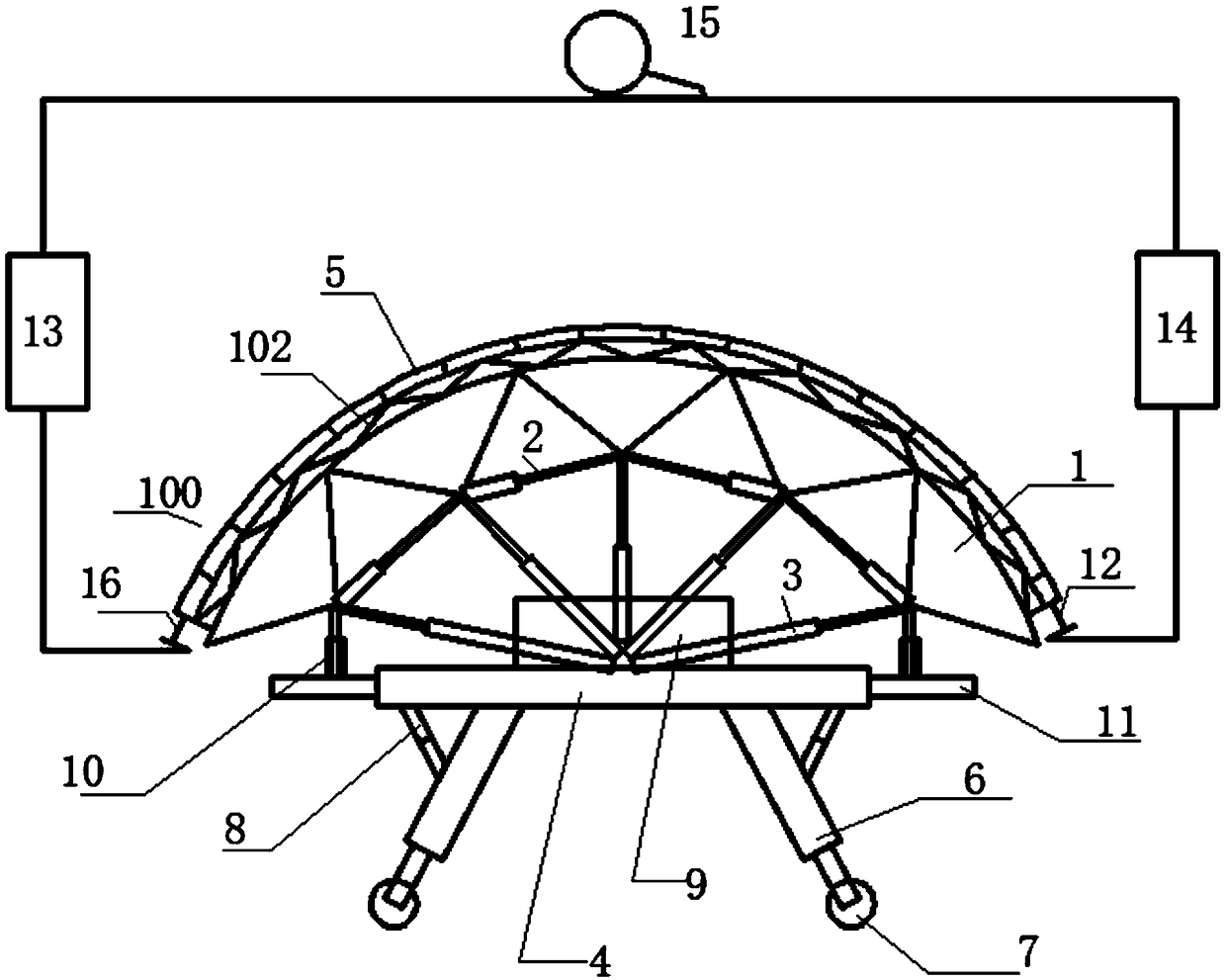

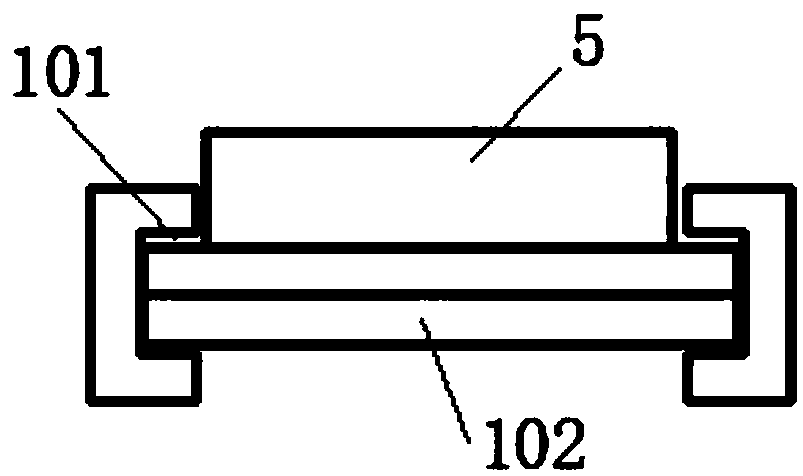

[0023] Such as Figure 1-2 As shown, a rotary kiln adjustable bricklaying machine with an expansion bladder of the present invention includes a bricklaying machine platform 9 and outriggers 6, the outriggers 6 are hydraulic telescopic outriggers, and the bottom of the bricklaying machine platform 9 is provided with two-way hydraulic Adjust the jack 4, the bottom of the two-way hydraulic adjustment jack 4 is connected obliquely with a leg 6, the bottom of the leg 6 is provided with a roller 7, and an adjustable support rod 8 is also arranged between the leg 6 and the main body of the two-way hydraulic adjustment jack 4. The rotary kiln adjustable bricklaying machine also includes a kiln wall support unit. The kiln wall support unit is hinged by a plurality of triangular truss units 1. The outer rods of the triangular truss unit 1 are arc-shaped. They are connected by a one-way telescopic adjustable jack 2, and the two ends of the telescopic adjustable jack 2 are respectively hi...

Embodiment 2

[0025] In this embodiment, the telescopic adjustment jack 2 is a two-way telescopic adjustment jack, and the hydraulic pressure source and the air pressure source corresponding to the two-way hydraulic adjustment jack 4, the telescopic adjustment jack 2, the telescopic adjustment hydraulic rod 3, and the air pressure adjustment pallet device 5 All are connected with the control platform, and the telescopic adjustment control is performed uniformly through the control platform, so as to facilitate the coordinated telescopic control of the kiln wall support unit as a whole. At the same time, the expansion bag 5 is filled with water and connected with a monitoring device to automatically monitor the inflation pressure. The roller blind 102 is also provided with an automatic traction and contraction device, so that it can automatically slide along the slideway 101 and automatically cover the wall tiles. Other structures are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com