Cable rope tension releasing device

A release device and cable rope technology, which is applied in the field of tension release devices, can solve the problems that the release device cannot be adjusted automatically and the tension of the cable rope can be released at will, and achieve the effect of simple structure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

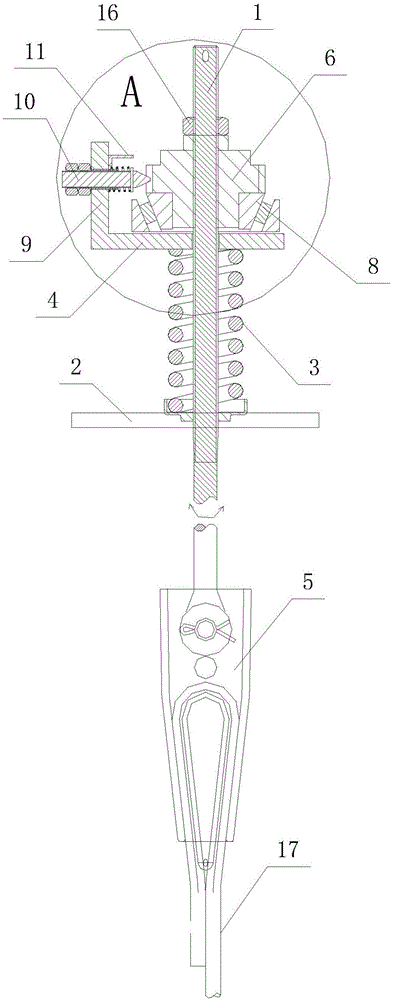

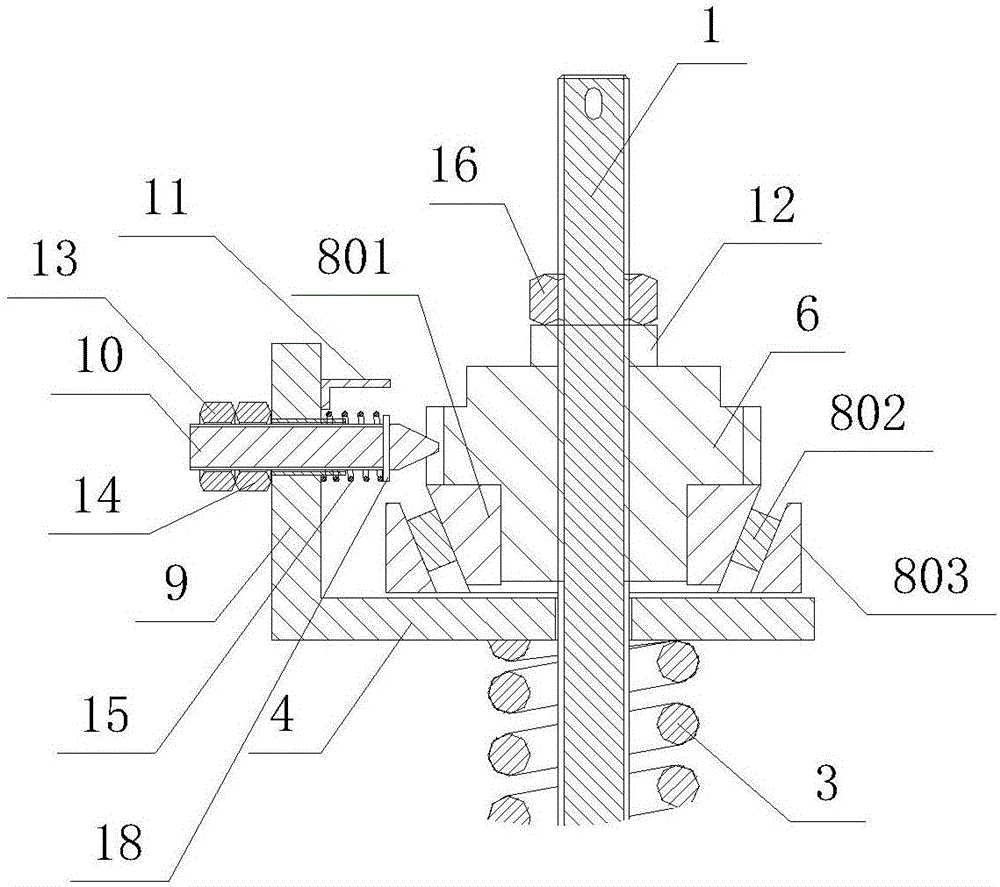

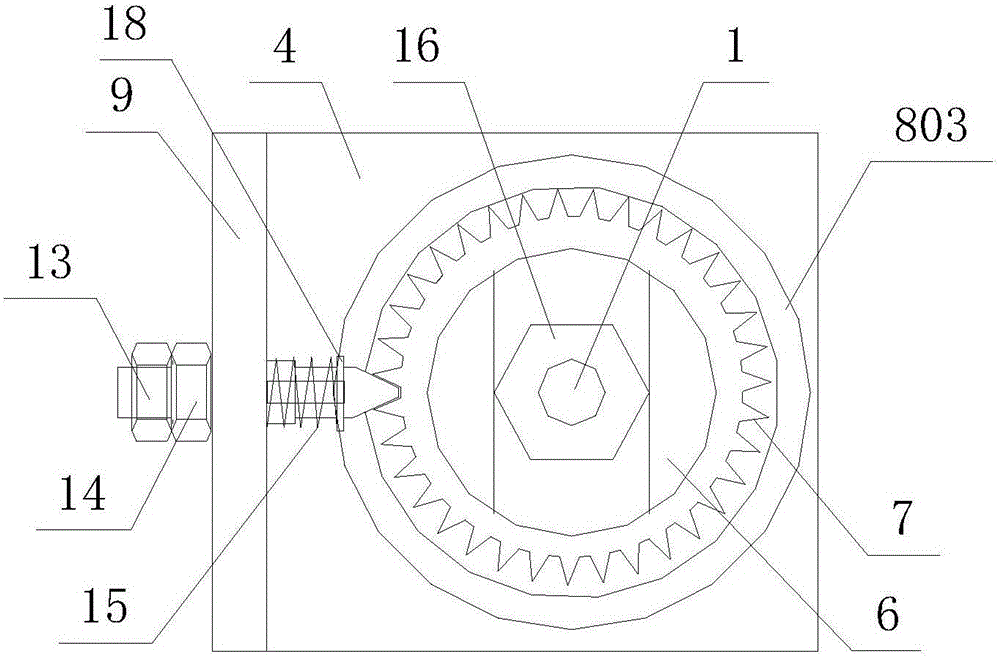

[0015] Such as Figure 1 to Figure 3 As shown, a cable tension release device includes a pull rod 1 and a rope head plate 2 , an elastic element 3 , and a horizontal plate 4 that are sheathed on the pull rod 1 in sequence from bottom to top. The outer surface of the pull rod 1 is provided with external threads, and the bottom end of the pull rod 1 is connected with a rope end taper 5 . The pull rod 1 is covered with a tension release sleeve 6, and the inner hole of the tension release sleeve 6 is provided with an internal thread, so that the tension release sleeve 6 is threadedly connected with the pull rod 1, and a lock is also threaded on the pull rod 1. Nut 16, lock nut 16 is tightened, forms self-locking with described tension releasing bushing 6, just makes tension releasing bushing 6 be fixedly sleeved on described pull rod 1 like this, tension releasing bushing 6 will follow pull rod 1 turn together. The outer circumference of the tension release sleeve 6 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com