Rotor testing machine of hybrid power oil cooling system

An oil cooling system, hybrid technology, applied in the field of motors, can solve problems such as increased workload, motor mixing, customer complaints, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below according to the accompanying drawings.

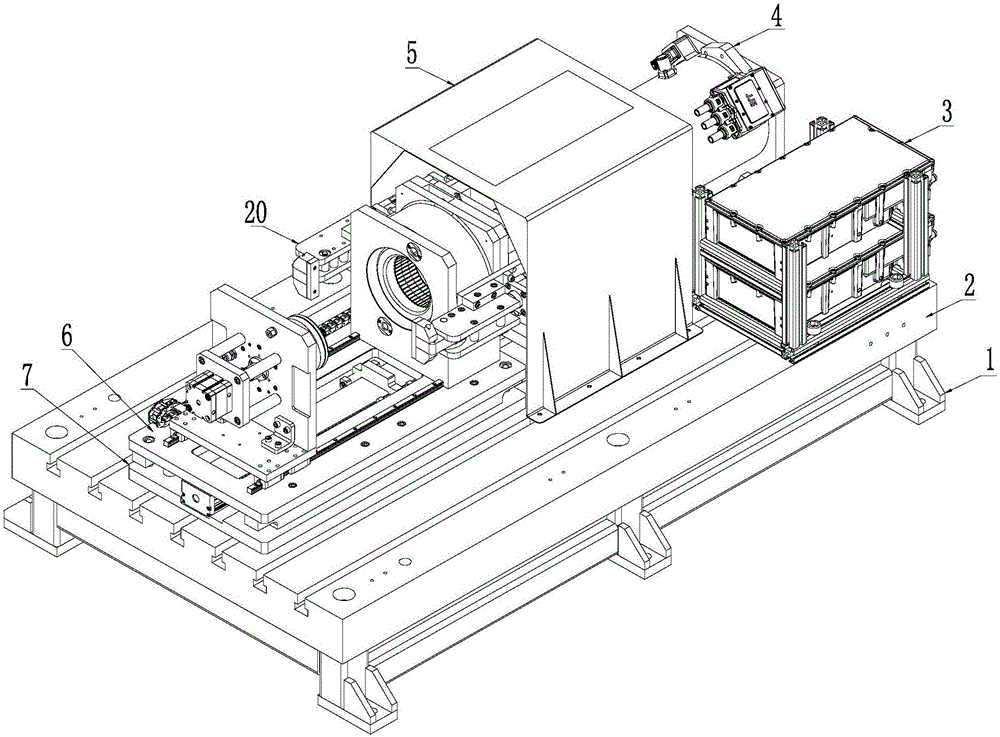

[0023] Such as figure 1 As shown, a platform 2 is provided on the top of the base 1, a tooling machine 7 is connected to the platform 2, a test platform 6 is connected to the tooling machine 7, and a test tool is provided on the test platform 6. One side is connected with the driving device 4, and the outer side of the test tool is covered with a protective cover 5.

[0024] A control cabinet 3 is arranged on the platform 2 in front of the driving device 4 .

[0025] The platform 2 that is positioned at protective cover 5 front sides is provided with frock clip 20.

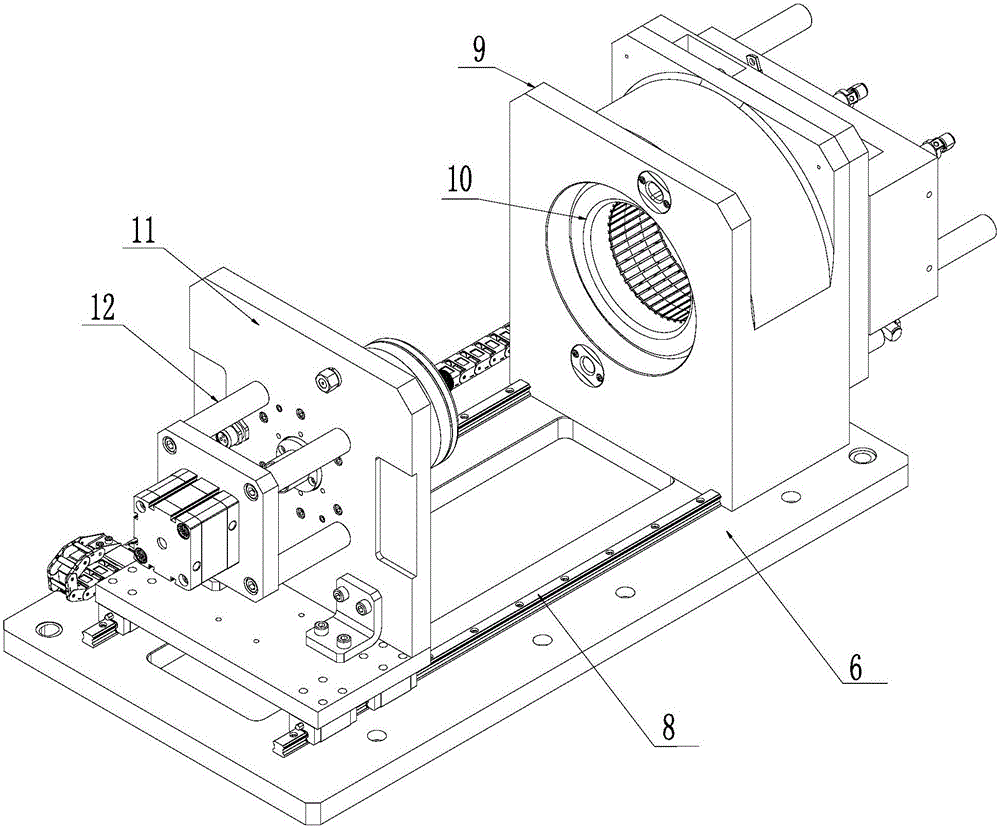

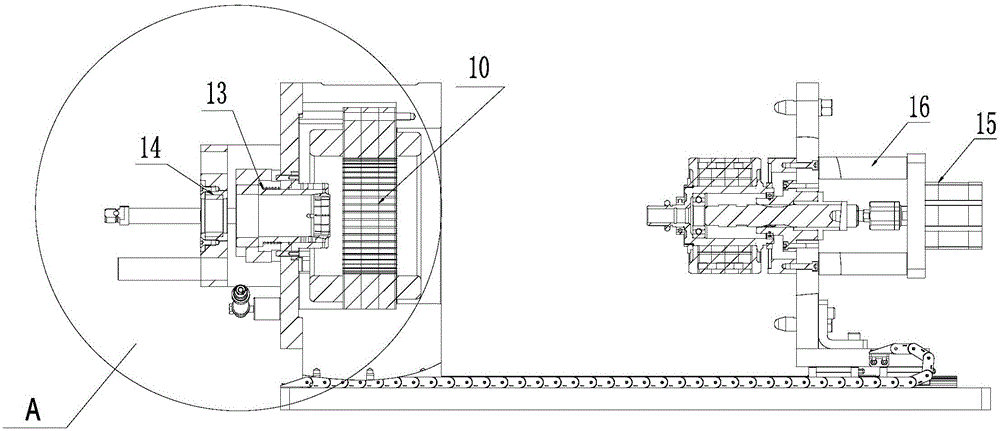

[0026] Such as Figure 2 to Figure 4 As shown, the test tooling includes a rotor clamping device, a slide rail, a rotor holder, a stator, a stator seat, a front bearing holding mechanism, and a rotating shaft anti-jump system. The left side of the test platform 6 is connected to the rotor holder 11 by a slide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com