Automatic production equipment of connecting rod type detonator vertical receiving boxes

A production equipment and link-type technology, applied in the field of automatic production equipment for link-type detonator vertical box collection, can solve the problems of failure to realize human-machine isolation, high risk of personnel, and easy danger, so as to improve production safety , Reduce labor intensity and reduce the effect of staff

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

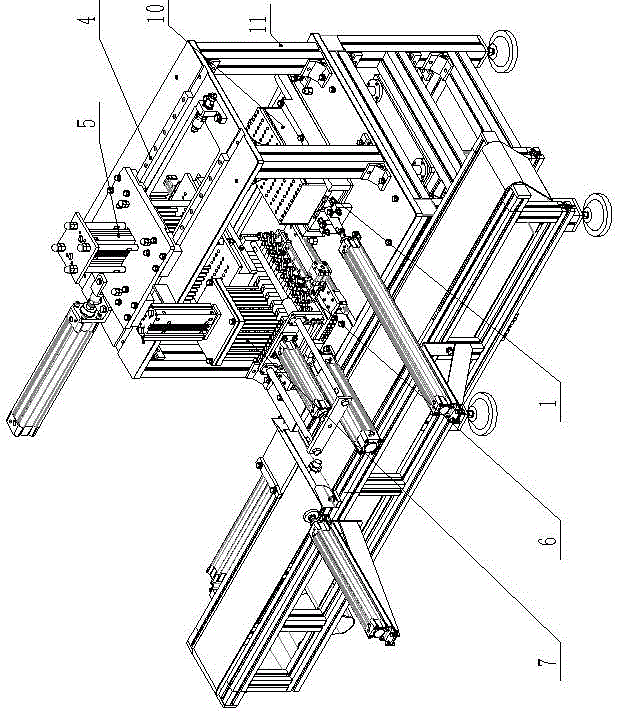

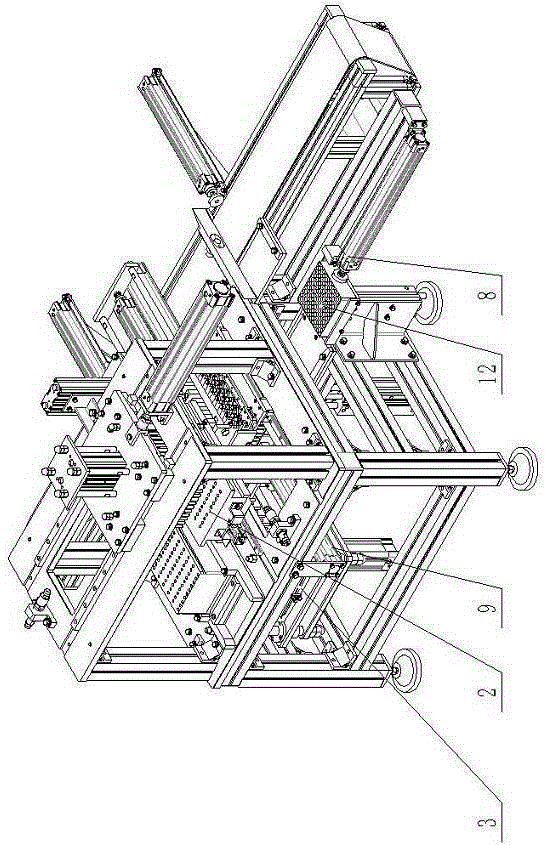

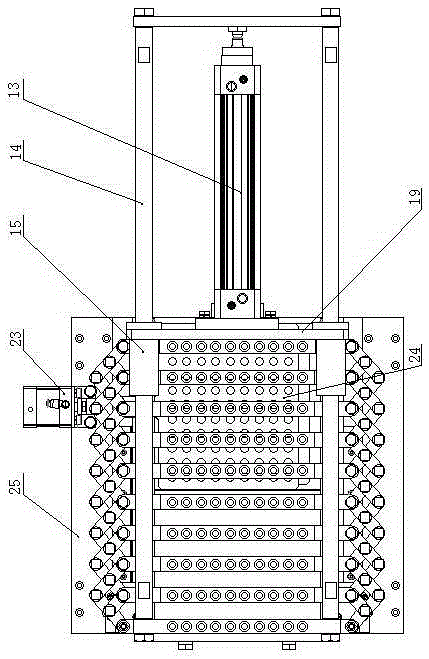

[0018] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

[0019] see figure 1 and figure 2 As shown, in the automatic production equipment for connecting rod type detonator vertical box receiving of the present invention, the detonator mold 10 is automatically transferred to the workbench and positioned by the die-drawing mechanism 1, and the detonator in the detonator mold 10 is sent to the transition through the pipe-jacking mechanism 3. In the collecting block 2, the transitional collecting block 2 is translated by the translation mechanism 4 to the top of the retracting device 6 that converts the spacing of the detonators, and the detonators in the transitional collecting block 2 are sent into the retracting device 6 through the tube feeding mechanism A5, and the detonators after the converted spacing are passed through the tube feeding device. Mechanism B7 is sent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com