Display device and 2D display mode realization method

A technology of a display device and a realization method, which is applied in the field of 2D/3D display, can solve the problems such as the electro-optic refractive index is not strictly phased, achieve the effect of alleviating the high requirements of the manufacturing process, overcome the lens residue, and achieve good 2D display effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

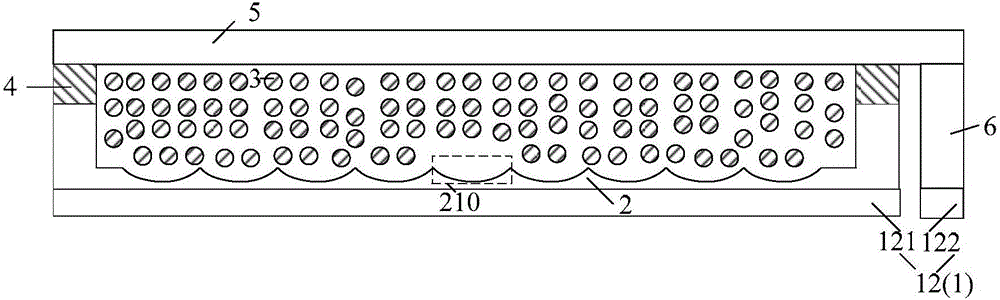

[0042] The structure of the display device is as figure 1 As shown, wherein, the lenticular lens film is a concave lens film, the material of the film has a refractive index n, the electro-optic material is a liquid crystal molecule, and the minimum and maximum values of the refractive index are respectively n o (i.e. n 1 ) and n e (i.e. n 2 ), where n-n o e -n.

[0043] The voltage applied to the display device is 0V, ie V OFF =0V, at this time, the direction of the optical axis of the liquid crystal molecules is parallel to the polarization direction of the image light, so that the refractive index of the liquid crystal molecules is felt by the abnormal light refractive index n e , when the image light passes through the concave lens in the plano-concave lens film, it feels the effect of the convex lens to realize 3D display.

[0044] The applied voltage of the display device is adjusted so that the effective refractive index of the liquid crystal molecules is strict...

Embodiment 2

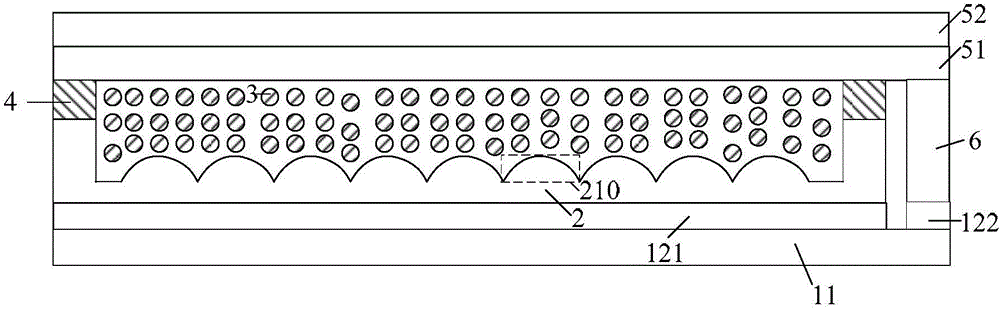

[0046] The structure of the display device is as figure 2 As shown, wherein the lenticular lens film is a convex lens film, the material of the film has a refractive index of n, the electro-optical material is a liquid crystal molecule, and the minimum and maximum values of the refractive index are respectively n o (i.e. n 1 ) and n e (i.e. n 2 ), where n e -no .

[0047] The voltage applied to the display device is V, ie V ON , at this time, the direction of the optical axis of the liquid crystal molecules is parallel to the thickness direction of the first substrate, while the polarization direction of the image light is still perpendicular to the paper surface, and the direction of the optical axis of the liquid crystal molecules is perpendicular to the polarization direction of the image light, so that the liquid crystal molecules The refractive index of ordinary light is felt as the refractive index n e , when the image light passes through the convex lens in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com